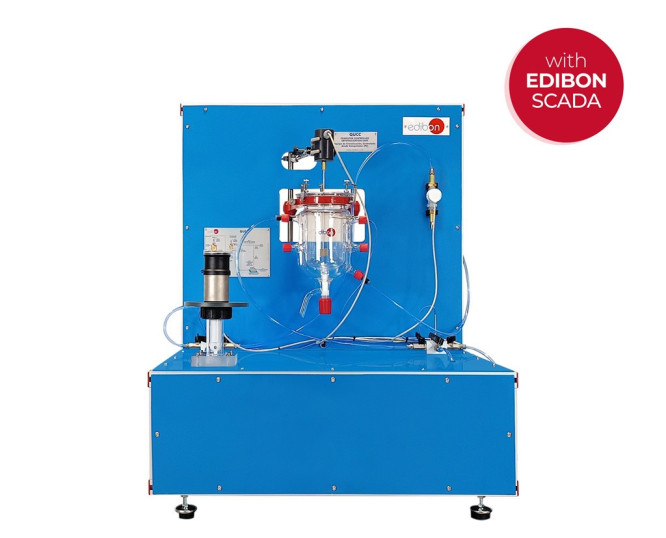

QUCC Computer Controlled Crystallization Unit

創新系統

The Computer Controlled Crystallization Unit, "QUCC", designed by EDIBON, is a cooling crystallization unit. Therefore, it is suitable to perform crystallization experiments with those constituents whose solubility changes according to the temperature.

扩展

化验室

相關新聞

一般說明

The Computer Controlled Crystallization Unit, "QUCC", is a unit for the study of the cooling crystallization process. EDIBON has designed this unit to study the crystallization reaction of those constituents whose solubility changes with the temperature.

This unit is devised to perform batch crystallization, that is, the crystallizer is filled once with the solute and solvent until the supersaturated solution is obtained and crystals are obtained from that solution.

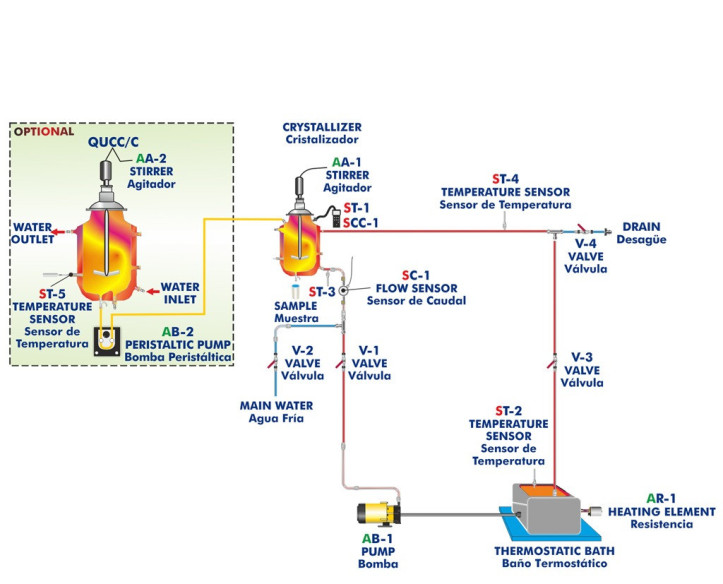

The "QUCC" unit includes a crystallizer, which is basically a jacketed chemical reactor. There is a bath outside the crystallizer, through which the reaction temperature is controlled. The solution is stirred by a stirrer located at the upper side of the crystallizer. Besides, there is a temperature sensor at the upper side of the crystallizer to know the temperature of the solution inside at any moment.

The unit also includes a conductivity sensor to know the conductivity of the solution when it is required.

To obtain the supersaturated solution, it must be heated so that it is able to dissolve a higher concentration of solute at high temperatures. There is a thermostatic bath to supply water to the crystallizer's jacket. Its control is done through the software by means of a PID.

Once a supersaturated solution at a high temperature is obtained, the crystallization stage starts. For that purpose introduce cold or room temperature water. The unit includes a pressure regulation valve kept to the minimum pressure.

A sample of the collected product is analyzed with the filters set provided with the unit. The size of generated crystals can be obtained thus.

With the additional recommended element Computer Controlled Continuous Feed Unit, "QUCC/C", this unit becomes a continuous crystallization unit.

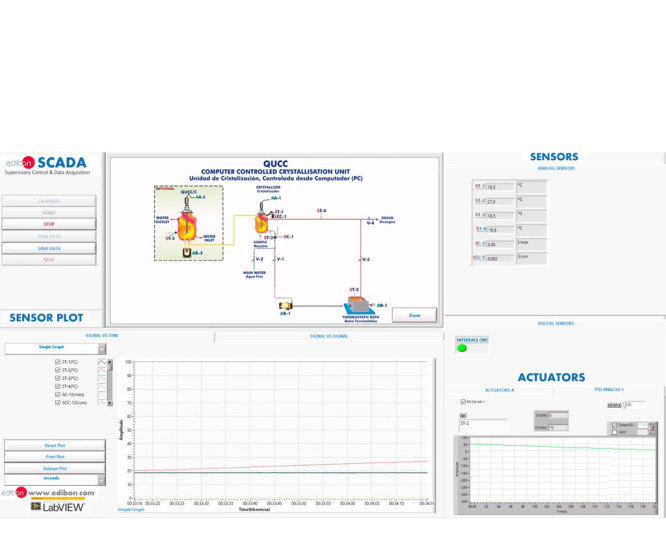

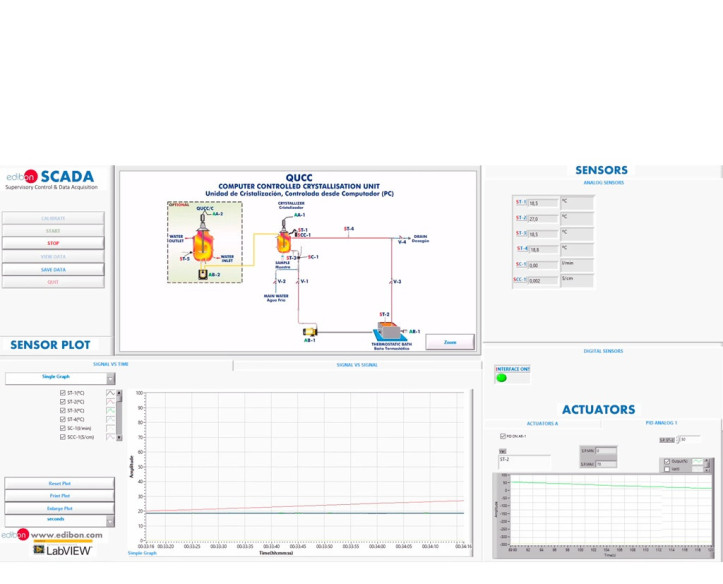

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

練習和指導練習

手册中包含的指导实践练习

- Understanding the principles of solution cooling crystallization.

- Study of crystal size distribution.

- Batch operation.

- Obtaining crystals by the cooling method.

- Demonstration of the effects of varying the following parameters on the crystallization process:

- Concentration of solute.

- Stirring level.

- Cooling temperature.

- Solute supply flow ("QUCC/C" is required).

与该单位进行更多实际操作

- Sensors calibration.

- Mass and energy balances.

- Evaluation of crystallization efficiency and crystallization kinetics.

- Operation in continuous ("QUCC/C", is acquired).

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QUCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QUCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user

可用的类似设备

Advanced Crystallization Unit

计算机控制的高级结晶设备

配套设备

Crystallization Unit

计算机控制的高级结晶设备

Advanced Crystallization Unit

Computer Controlled Pyrolysis Unit

質量

售後服務

Cookies首选项

Cookies首选项