At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

ADSG 驱动、轴和齿轮对准设备

創新系統

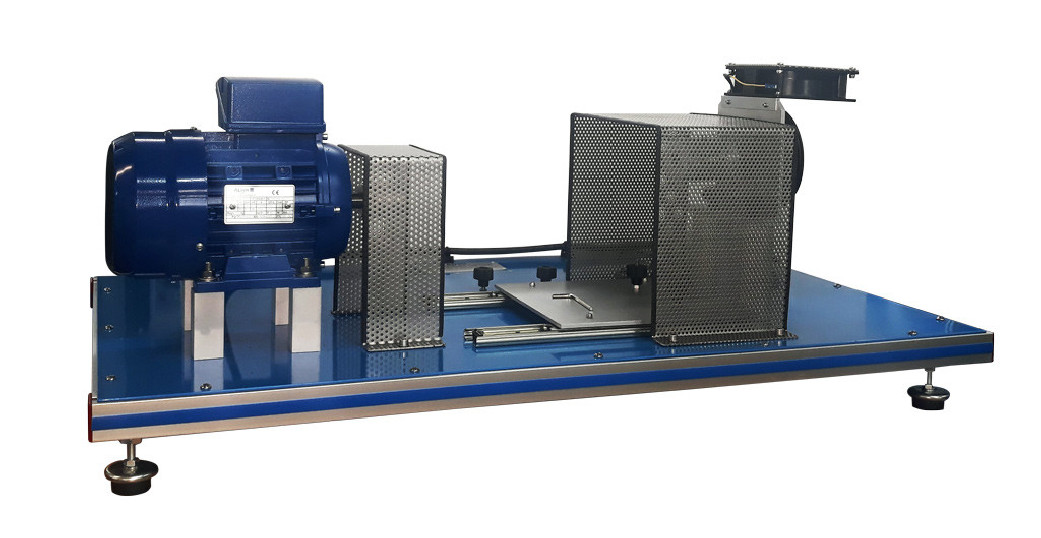

The Drive, Shaft, and Gear Alignment Unit, "ADSG", allows for studying the coupling and uncoupling, maintenance, repair of the related units and checking the operation.

相關新聞

一般說明

The Drive, Shaft, and Gear Alignment Unit, "ADSG", allows for studying the coupling and uncoupling, maintenance, repair of the related units and checking the operation with the following units:

- CGA. Combined Gear Assembly Unit.

- SGA. Spur Gear Assembly Unit.

- SJBA. Unit to Study a Shaft with Journal Bearings Assembly.

Any of the elements included in those three units will be correctly mounted in this unit in order to align the elements, mount the system and check the operation. Heat generation, vibrations during operation and possible leaks can also be assessed.

The unit includes a rigid bench with aluminum profile. The single-phase asynchronous drive motor with metal bellows coupling and the driving element to be checked are located on that bench.

It is possible to change the mounting space, by adapting it to the size of the drive element. It also has a magnetic particle brake with adjustable braking torque regulated by a potentiometer.

The drive element is coupled to the motor and the brake through two couplings protected by removable guards. The objective of the student will be to perform the element-brake and element-motor alignments.

The excitation current of the magnetic brake, indicated in a display, is used to measure the braking torque. The magnetic brake includesa fan.

練習和指導練習

手册中包含的指导实践练习

- Assembly and alignment of gears (it requires the required element "CGA").

- Testing the final operation of a spur gear with worm gear (it requires the required element "CGA").

- Familiarization with gear components and their functions (it requires the required element "CGA").

- Checking the gear behavior when working with a variable load (it requires the required element "CGA").

- Study and assessment of vibrations and noise during the operation of the gear with a variable load and checking for leaks (it requires the required element "CGA").

- Study and analysis of the gear function assembled with a test load (it requires the required element "CGA").

- Assembly and alignment of a shaft with journal bearings (it requires the required element "SJBA").

- Testing the final operation of a shaft with journal bearings (it requires the required element "SJBA").

- Familiarization with gear components and their functions (it requires the required element "SJBA").

- Checking the sliding quality of the journal bearing.

配套设备

7.4.3.- 安装和维护惯例

MDUC

The Computer Controlled Machine Diagnosis Unit, "MDUC", of EDIBON, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The Computer...

7.4.3.- 安装和维护惯例

MDU

机器诊断

The family of Machine Diagnosis Unit, "MDU", of EDIBON, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The MDU Base Unit, "MDU-UB",...

7.4.3.- 安装和维护惯例

MDU-MLB

MDU设备移动结构

The Mobile Structure for MDU, "MDU-MLB", is a robust structure designed to quickly and easily assemble the various elements of the MDU Base Unit, "MDU-UB" or the Computer Controlled Machine Diagnosis Unit, "MDUC", and thus assemble a mobile test...

7.4.3.- 安装和维护惯例

MDU-SM

MDU设备桌面结构

A bench-top structure consisting of a slotted table with anodized aluminum frames of 1100 x 770 x 820 mm.It has a transparent protective cover that protects against the rotating parts and allows us to observe the different experiments. The cover...

7.4.3.- 安装和维护惯例

MDU-SSC

MDU设备的软件、传感器和控制

The aim of the vibration analyzer is to assess the machine diagnosis testing with the different kits related to the vibration interface technology.The system consists of two acceleration sensors, a speed sensor, a measuring amplifier with...

7.4.3.- 安装和维护惯例

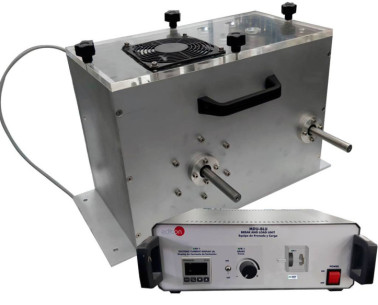

MDU-BLU

制动和负载设备

The Break and Load Unit, "MDU-BLU", of EDIBON is a magnetic particle brake, a display unit and an electrical control. It is possible to precisely adjust the braking moment. The excitation current is used as a measurement of the braking moment and...

7.4.3.- 安装和维护惯例

MDU-SES

弹性树套装

The Set of Elastic Shaft, "MDU-SES", of EDIBON allows to study the behavior of an elastic rotor subjected to imbalance and balance of elastic rotors in operation. It is possible to study the resonance and the phenomena occurred in subcritical and...

7.4.3.- 安装和维护惯例

MDU-SRS

裂纹轴套装

It is important that fissures resulting from material fatigue in rotating machines are detected in good time before the breakage occurs, which usually leads to fatal consequences.The Set of Rotating Shaft with Crank, "MDU-SRS", consists of two...

7.4.3.- 安装和维护惯例

MDU-SRBF

轴承缺陷套装

To determine the remaining life cycle of a roller bearing and decide on its replacement, the slow variation of the vibration spectrum is analyzed. The spectral distribution will enable to draw accurate conclusions about the type of defect and its...

7.4.3.- 安装和维护惯例

MDU-SCO

连接件套装

The Set of Couplings, "MDU-SCO", allows to compare the properties of different couplings such as curved tooth, bolt, flange and claw couplings.The vibrational behavior of the different types of couplings is important to draw conclusions about...

7.4.3.- 安装和维护惯例

MDU-SBD

皮带传动套装

The belt drives are noiseless drive devices, have a long life and require little maintenance provided that its design, assembly and adjustment are correct.The Set of Belt Drive, "MDU-SBD", allows to study the conditions that cause vibrations or...

7.4.3.- 安装和维护惯例

MDU-SSDG

齿轮缺陷套装

The Set to Study Damage in Gears, "MDU-SSDG", allows to study the vibrational behavior of gears with typical defects.For that purpose, gears with tooth defects and gears without defects are included, so a comparative study can be carried out. The...

質量

售後服務

Cookies首选项

Cookies首选项