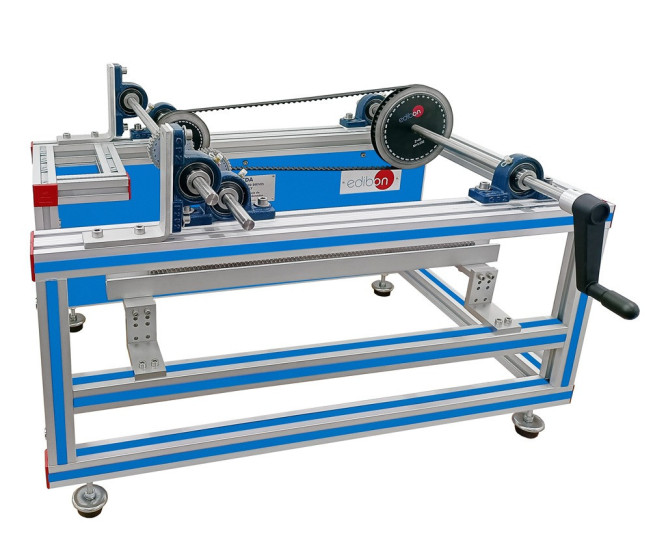

The Unit to Study Combined Drives Assembly, "MCDA", designed by EDIBON, allows carrying out advanced exercises and provides an understanding of the significant components and arrangements of the mechanical drive technology.

With this unit, practices can be carried out to ensure the learning of six simple forms of drive in different combinations. Through these six simple forms of drive, different configurations can be made putting your own ideas into practice.

Some configurations that can be carried out are: a combined drive of a worm and bevel gears, a combined drive of a spur gear and a worm, a combined drive of spur and bevel gears, a double-belt drive, a double spur gear, a rack gear with spur gear drive and chain drive, and a spur gear drive.

The steps that need to be followed to ensure an appropriate learning are:

- Approach to tasks and understanding of diagrams.

- Part assembly and adjustment, gear calibration and verification.

- Carrying out relevant calculations.

The unit drive will be carried out through a flywheel. A high level of precision will be obtained in gear adjustment thanks to the anodized aluminum frame.

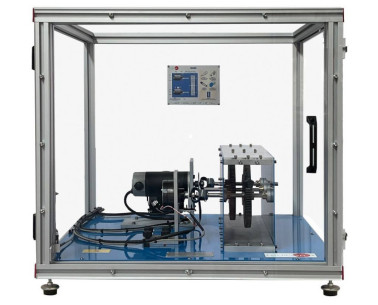

A carrying case will be provided to facilitate the transport and ensure the protection of the components required for the assembly and learning.

Cookie-Präferenzen

Cookie-Präferenzen