CPIC Industrielles Prozessleitsystem, computergesteuert (PC)

INNOVATIVE SYSTEME

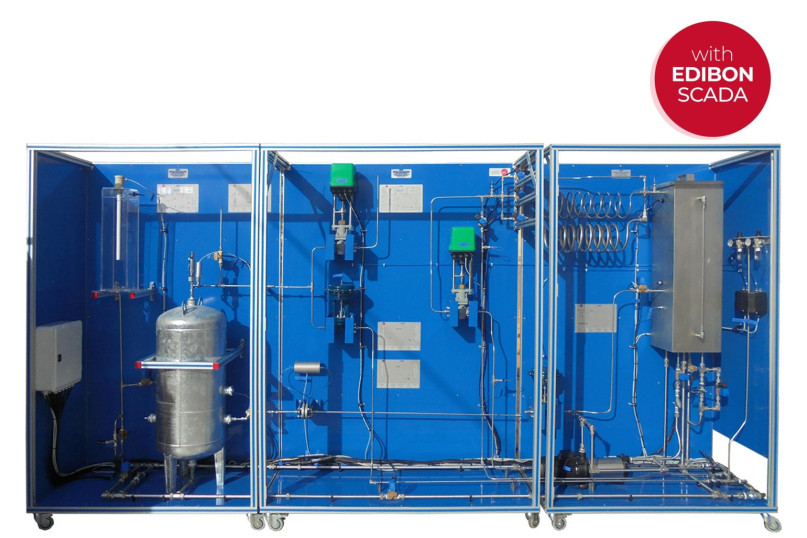

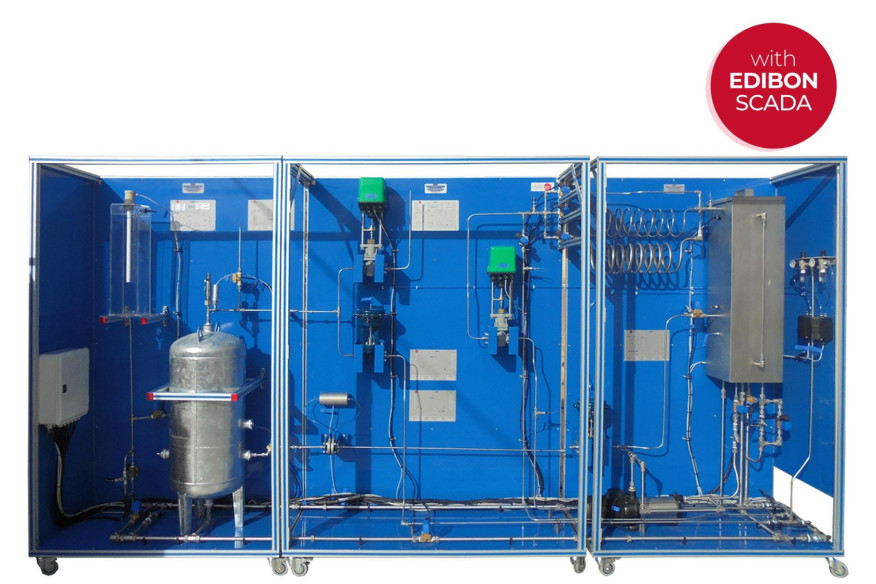

The The Computer Controlled Industrial Process Control Plant, "CPIC", designed by EDIBON, allows users to understand the complexity of industrial automation, observe the interaction between different variables, and analyze how changing a setpoint affects process stability, bringing them closer to the reality of industrial plants.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The The Computer Controlled Industrial Process Control Plant, "CPIC", designed by EDIBON, allows users to understand the complexity of industrial automation, observe the interaction between different variables, and analyze how changing a setpoint affects process stability, bringing them closer to the reality of industrial plants.

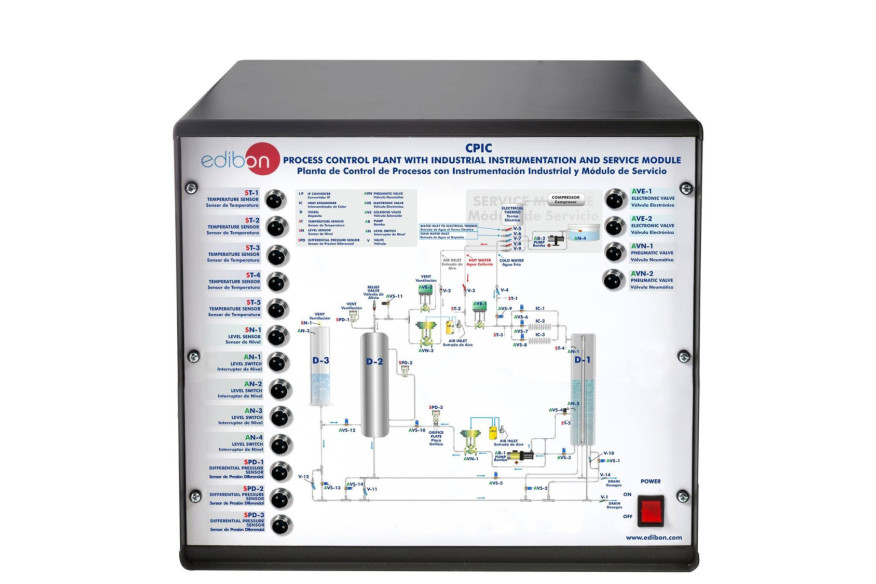

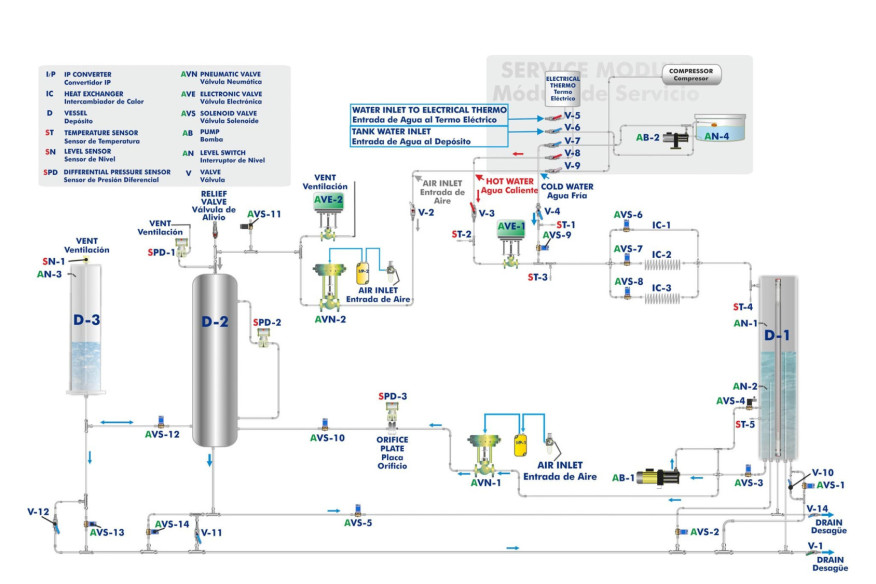

The "CPIC" is composed of a service module and a main unit:

- The service module supplies the necessary resources for operation: cold water, hot water, and compressed air. It includes a compressor that regulates air pressure, a cold-water tank with level control, a booster pump, and a tank with a heating element to provide hot water. In this way, the "CPIC" faithfully reproduces the auxiliary service infrastructure present in any industrial facility.

- The main unit integrates three tanks with different characteristics, enabling control experiments:

- The first tank, open to the atmosphere, is used for the temperature control loop, with different water inlet and outlet points that allow the study of the mixing effect of cold and hot flows.

- The second tank, pressurizable up to 4 bar, is used for flow, pressure, and level control loops, thanks to a differential pressure sensor that ensures operational safety.

- Finally, the third tank, transparent and open to atmospheric pressure, is equipped with level sensors and an automatic safety drain system, making it possible to study level control under real and visible conditions.

To regulate the variables, the "CPIC" incorporates electronic control valves working with PID controllers, as well as fast-acting pneumatic valves, allowing the simulation of common maneuvers in industrial processes. The unit also includes flow, pressure, level, and temperature sensors, which transmit real-time data to the control system.

The configurable design of the "CPIC" allows the study of up to five different control loops: temperature, flow, pressure, and tank levels.

This flexible configuration makes the "CPIC" a comprehensive solution for learning from basic fundamentals to more advanced control situations.

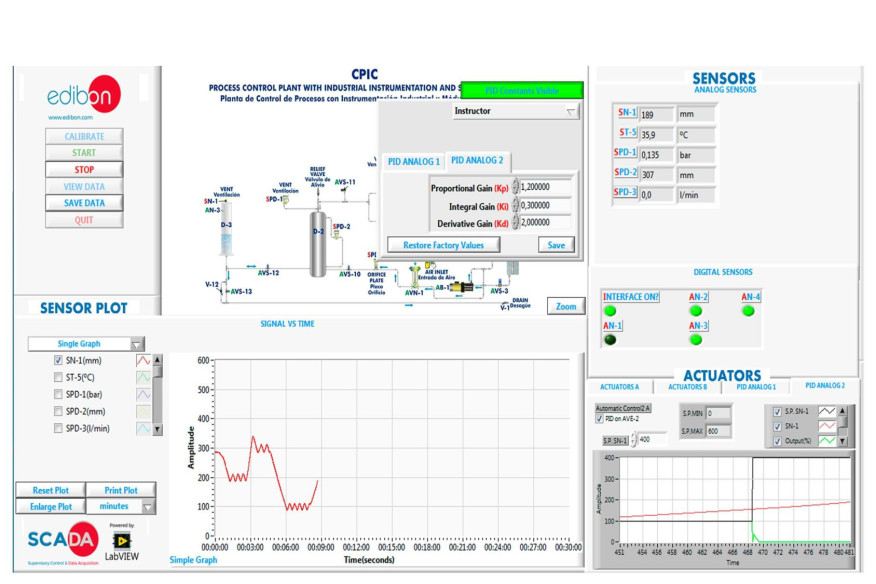

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Zubehör

Industrielles Prozesskontrollsystem (nur Temperatur), computergesteuert (PC)

Industrielles Prozessleitsystem (nur Level), computergesteuert (PC)

Industrielles Prozessleitsystem (nur Druck),computergesteuert (PC)

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Familiarization with the different components of the system and their symbolic representation. Identification of components and description of their functions.

- The auxiliary systems: air and hot water supply.

- Flow sensors calibration.

- Temperature sensors calibration.

- Level sensor calibration.

- I/P converter calibration.

- Flow control loop (on/off).

- Flow control loop (proportional).

- Flow control loop (P+I).

- Flow control loop (P+D).

- Flow control loop (P+I+D).

- Adjust of the flow controller constants (Ziegler-Nichols).

- Adjust of the flow controller constants (reaction curves).

- Search of simple shortcomings in the loop of flow control.

- Temperature control loop (on/off).

- Temperature control loop (proportional).

- Temperature control loop (P+I).

- Temperature control loop (P+D).

- Temperature control loop (P+I+D).

- Adjust of the temperature controller constants (minimum area or reduction rate).

- Adjust of the temperature controller constants (minimum disturbance criterion).

- Adjust of the temperature controller constants (minimum width criterion).

- Study of the retards for speed/distance, exemplified through the temperature control loop.

- Study of the energy lost in the temperature control loop.

- Search of simple shortcomings in temperature control loop.

- Level control loop (on/off).

- Level control loop (proportional).

- Level control loop (P+I).

- Level control loop (P+D).

- Level control loop (P+I+D).

- Adjust of the level controller constants (minimum area or reduction rate).

- Adjust of the level controller constants (minimum disturbance criterion).

- Adjust of the level controller constants (minimum width criterion).

- Search of simple shortcomings in level control loop.

- Pressure control loop (on/off).

- Pressure control loop (proportional).

- Pressure control loop (P+I).

- Pressure control loop (P+D).

- Pressure control loop (P+I+D).

- Adjust of the pressure controller constants (minimum area or reduction rate).

- Adjust of the pressure controller constants (minimum disturbancecriterion).

- Adjust of the pressure controller constants (minimum width criterion).

- Search of simple shortcomings in the pressure control loop.

- The use of the controllers in cascade, exemplified with the level/flow control loop.

- Adjust of cascade control constants (minimum area or reduction rate).

- Adjust of cascade control constants (minimum disturbance criterion).

- Adjust of cascade control constants (minimum width criterion).

- Search of simple shortcomings in cascade control loop.

- Practical operation of the control plant to some wanted specific values: transfers without interferences.

- Calculation of the fluid flow in function of the differential pressure sensor.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the CPIC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the CPIC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Gekoppeltes Tanksystem, gesteuert über Computer (PC)

Prozesssteuerung (elektronisches Ventil), computergesteuert (PC)

Prozesssteuerung (pneumatisches Ventil), computergesteuert (PC)

Prozesssteuerung (Frequenzumrichter), computergesteuert (PC)

Prozesssteuerung (elektrisches + pneumatisches Ventil und Frequenzumrichter), computergesteuert (PC)

Gerät für Prozesssteuerung zur Untersuchung von Druck (Luft), computergesteuert (PC)

Industrielles Prozessleitsystem (nur Durchfluss), computergesteuert (PC)

Industrielles Prozesskontrollsystem (nur Temperatur), computergesteuert (PC)

Industrielles Prozessleitsystem (nur Level), computergesteuert (PC)

Industrielles Prozessleitsystem (nur Druck),computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen