MPCO Gerät zur Untersuchung der Druckverteilung in Lagern

INNOVATIVE SYSTEME

The Journal Bearing Unit, "MPCO", designed by EDIBON, allows to study the pressure distribution in sliding bearings.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

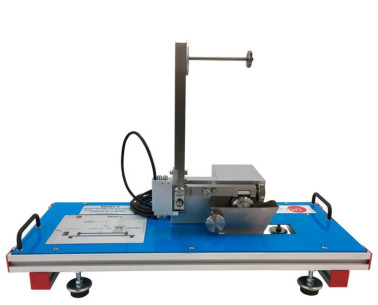

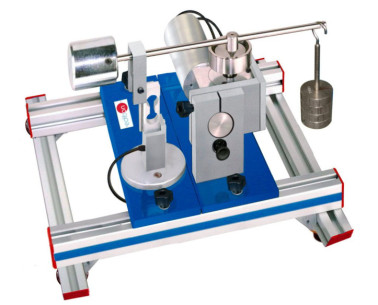

The Journal Bearing Unit, "MPCO", designed by EDIBON, allows to study the pressure distribution in sliding bearings. It illustrates the principle of hydrodynamic lubrication.

The unit is mounted on a metallic structure assembled on wheels for its mobility.

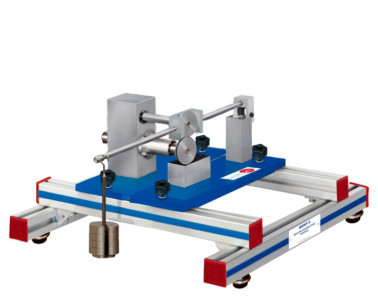

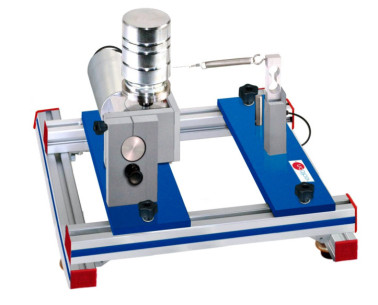

The sliding bearing consists of a journal bearing driven by an electrical motor and a freely moving bearing housing. The bearing can be loaded with different interchangeable weights. The journal bearing shifting and the oil film can be seen through a transparent bearing housing.

The distribution of pressure and the carrying capacity can be determined on a sliding bearing model at different bearing loads and speeds.

The radial and the axial distribution of pressure of the oil film in the sliding bearing can be recorded in the bearing gap at 12 equi-spaced pressure tappings around its perimeter and four along the length. All pressure tappings are connected by flexible plastic tubes to the rear multi-manometer panel with 16 tube manometers mounted on board, to show the pressure of oil at all 16 points at all times.

The loads are applied using a hanger and a weights set. The motor speed is controlled from an electronic console.

The unit includes an adjustable methacrylate tank to fill it with oil.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Demonstration of the principle of hydrodynamic lubrication.

- Relocation of the shaft journals in relation to speed.

- Determination of the pressure distribution in the bearing with constant load and at various speeds.

- Comparison of theoretical pressure profiles with practical results.

- Observation of oil wedge (film thickness) and hence eccentricity variations for different speeds and loads.

- Demonstration of the critical speed in relation to load.

- Demonstration of the critical speed and viscosity in relation to oil temperature.

- Demonstration of self-excited vibrations.

ERGÄNZENDE AUSRÜSTUNG

Gerät zur Untersuchung der Reibung

Modulares Gerät für Tribologie

Gerät für Antriebsversuche in der Tribologie

Radiale Druckverteilung in einem Gleitlager

Dynamische Reibung eines Zylinders auf einer Walze

Dynamische Reibung eines Bolzens auf einer Scheibe

Rollreibung bei Rädern

Elastohydrodynamische Schmierung

Reibungsschwingung

Gerät für einen dünnwandigen Zylinder

Gerät zur Untersuchung der Reibung in Lagern

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen