EGAC Gerät für Wasserschlag, computergesteuert (PC)

INNOVATIVE SYSTEME

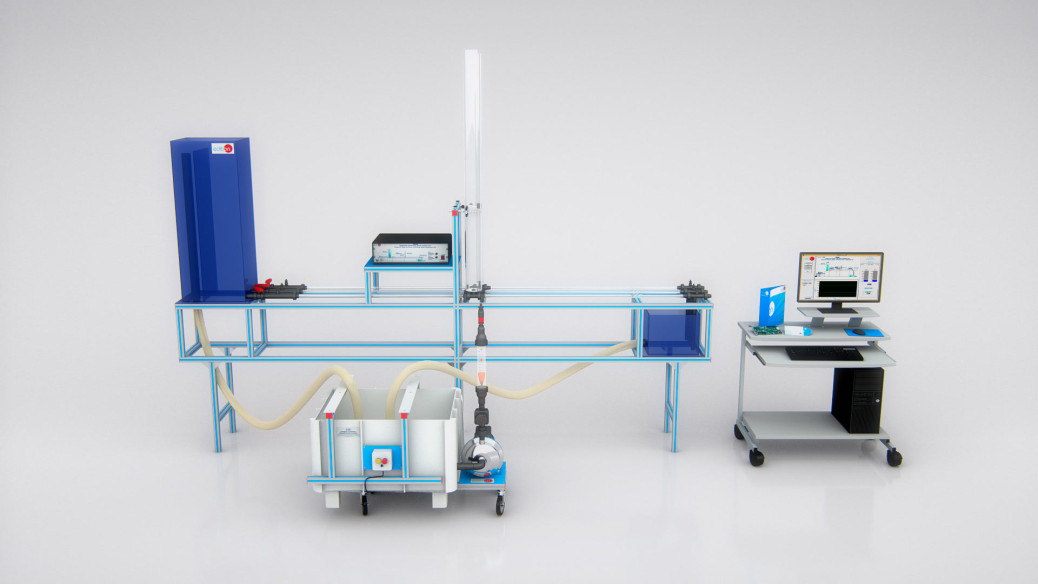

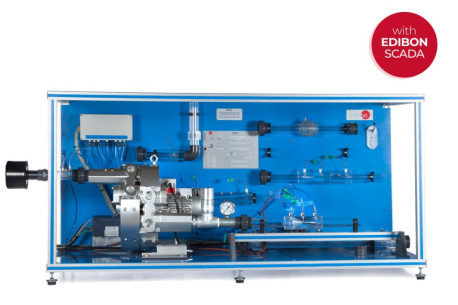

The Computer Controlled Water Hammer Unit, "EGAC", has been designed by EDIBON to demonstrate the effects of an instantaneous variation of the speed of a fluid. It is possible to study the water hammer, which is the consequence of a quick change in a fluid speed.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

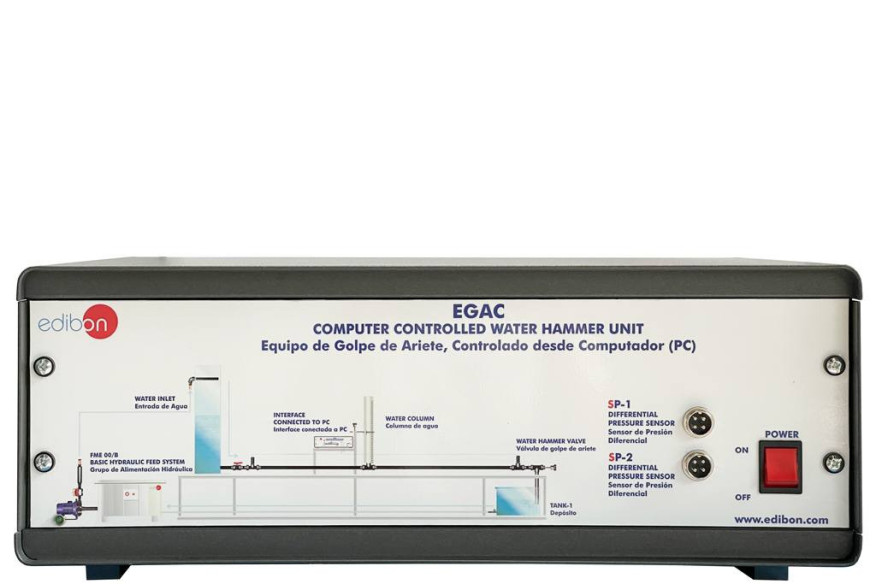

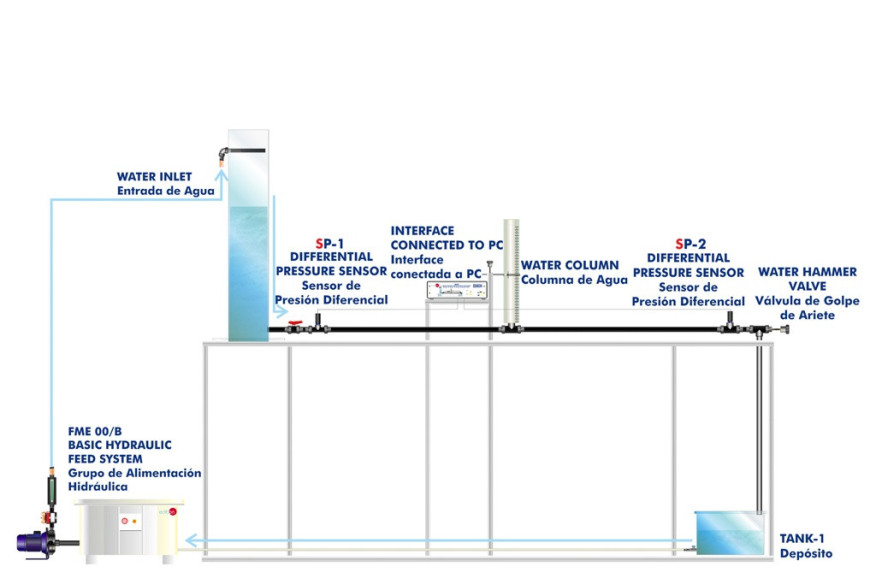

The Computer Controlled Water Hammer Unit, "EGAC", is designed to demonstrate the effects of an instantaneous variation of the speed of a fluid. It is possible to study the water hammer, which is the consequence of a quick change in a fluid speed.

Besides, damping of water hammer effects by using surge tanks can also be demonstrated.

The unit includes a hydraulic system with a centrifugal pump, which transfers water from the tank of the hydraulic system to the a constant level tank. This last tank supplies three different circuits to carry out the practical exercises. It can keep a constant pressure level at the three outlets by means of an inner wall. Besides, there is a valve that makes it possible to control the reflux from the hydraulic system to the constant level tank. A variable area flow meter is included to measure the reflux.

There are four testing circuits made of several materials and with different diameters to study their influence and to compare the results from every circuit. Each circuit has a quick-closing impact valve that generates the characteristic over-pressure of the water hammer. They also guarantee a quick closing without vibrations that could affect the measurements.

It also includes a discharge tank used to calm the water. Moreover, it provides the means of checking visually that the circuit under study is working.

Finally, there are three surge tanks which can be adapted to nine points of the system. They make it possible to study the conversion of the kinetic energy, released during the abrupt stopping of the water mass, into potential energy. Furthermore, the generated pressure vibrations can be analyzed by placing both pressure sensors at any of the twelve points of the circuits.

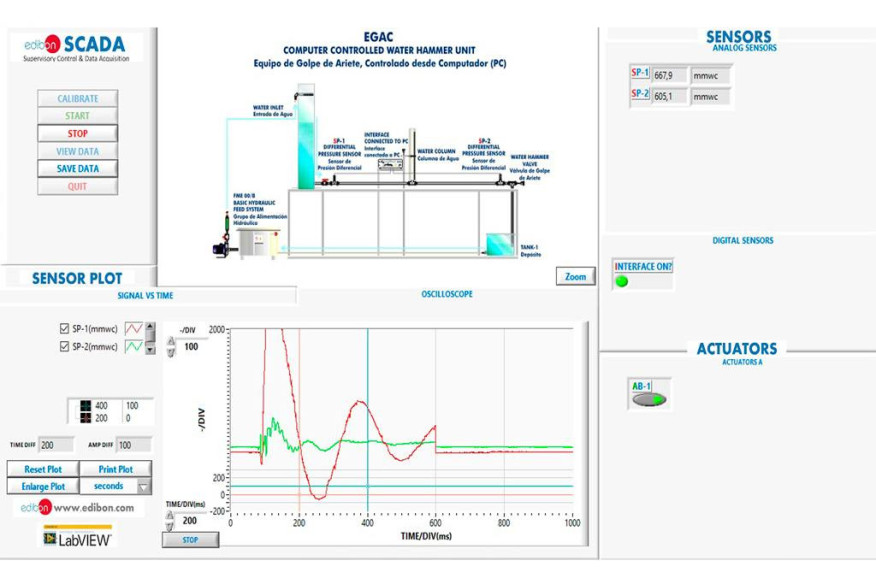

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Characterization of the water hammer phenomenon in pipes.

- Subduing the water hammer effects.

- Calculation of energy losses in pipes.

- Influences of the pipe diameter on the speed propagation.

- Subduing of the effects of the water hammer through abrupt expansions.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EGAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EGAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

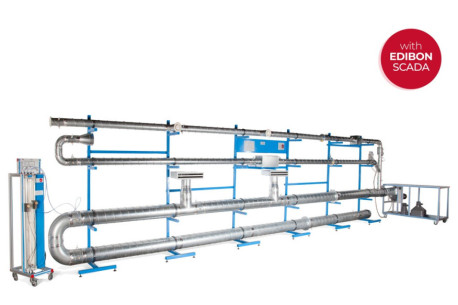

Gerät für Reibung in Rohrleitungen mit Hydraulikbank (FME00)

Gerät für Reibung in Rohrleitungen mit Hydraulikgruppe (FME00/B)

Gerät zur Reibung in Rohrleitungen

Gerät zur Siebung in Rohrleitungen, mit Hydraulikbank (FME00), Computergesteuert (PC)

Gerät zur Siebung in Rohrleitungen, mit Hydraulikbank (FME00)

Gerät zur Siebung in Rohrleitungen, mit Hydraulikgruppe (FME00/B)

Gerät zur Siebung in Rohrleitungen

Gerät zur Untersuchung des Druckverlustes von kompressiblen Flüssigkeiten in Rohrleitungen

Gerät für kompressible Strömungen, computergesteuert (PC)

Gerät für Prozesse nichtstationärer Entwässerung in Speichertanks, computergesteuert (PC)

Gerät für Luftkanalsysteme, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen