CEAB Gerät für Anwendungen mit Feldbus

INNOVATIVE SYSTEME

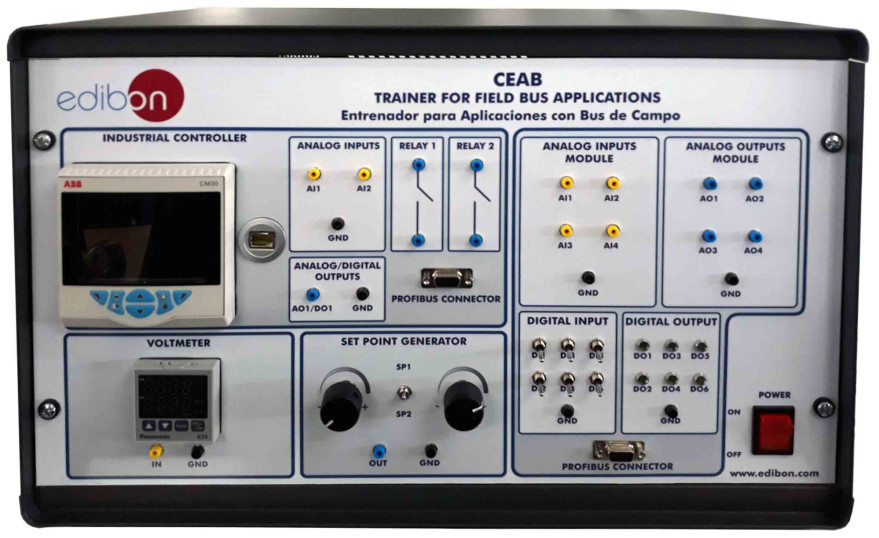

The Trainer for Field Bus Applications, "CEAB", provides the components to conform a real Profibus DP Network where the PC is the master device and different components included with the unit are the slave devices.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Trainer for Field Bus Applications, "CEAB", provides the components to conform a real Profibus DP Network where the PC is the master device and different components included with the unit are the slave devices. The "CEAB" unit also allows to study protocols conversion through a gateway device, with an example of conversion from Modbus RTU to Profibus DP.

The "CEAB" unit is based on a modular design structure whose functionality is divided into different modules to allow the student a better understanding of the unit. The modules provided with the unit are: Industrial controller, Analog Inputs Module, Analog Outputs Module, Digital Voltmeter, Set Point Generator, Digital Inputs Module, Digital Outputs Module, and the Interface Card.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the transfer function.

- Familiarize with the Set Point Generator, generation of a square signal using two analog signals.

- Familiarization with the operation with an industrial controller (operator page screen, trend display screen, etc).

- Operation and function of a digital industrial controller.

- Setting alarms and diagnosis generation.

- Familiarization with the Fieldbuses and the stations connected.

- Familiarization with the device master file "DMF".

- Network layout of the Profibus DP Fieldbus.

- Communication protocols.

- Installation, connection and familiarization with the software.

- Configuration of the Profibus DP network.

- Input/output mapping of the Industrial Controller and the digital and analog input and output device.

- Communication parameters configuration and reading the Profibus DP variables.

- OPC server configuration and creation of tags with an OPC client.

- Reading and writing the signal of the Digital and Analog Input and Output Profibus DP module with the OPC server.

- Setting the PID control parameters of an industrial controller with the front panel of the device.

- Setting the PID control parameters of an industrial controller with the OPC server.

ÄHNLICHE VERFÜGBARE GERÄTE

Industrielle Steuerungsnetzwerke

Gerät zur Einstellung von Reglern, computergesteuert (PC)

ERGÄNZENDE AUSRÜSTUNG

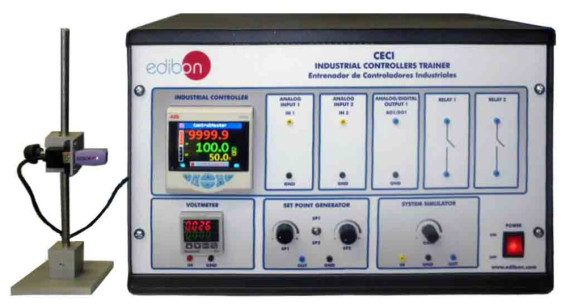

Gerät für Industrielle Regler

Industrielle Steuerungsnetzwerke

Gerät zur Einstellung von Reglern, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen