EFLPC Gerät für Tiefenbettsfiltration, computergesteuert (PC)

INNOVATIVE SYSTEME

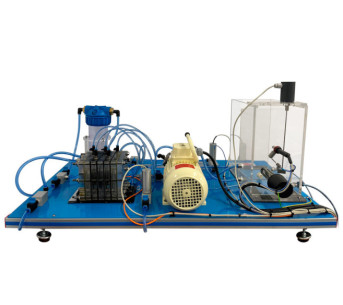

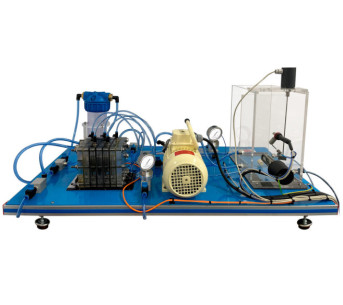

The Computer Controlled Deep Bed Filter Unit, "EFLPC", enables to study filtration in open and closed circuit, as well as to visualize the bed washing process.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Deep Bed Filter Unit, "EFLPC", allows us to filter a fluid in order to eliminate particles in suspension, to have it in more adequate conditions for its subsequent use or consumption.

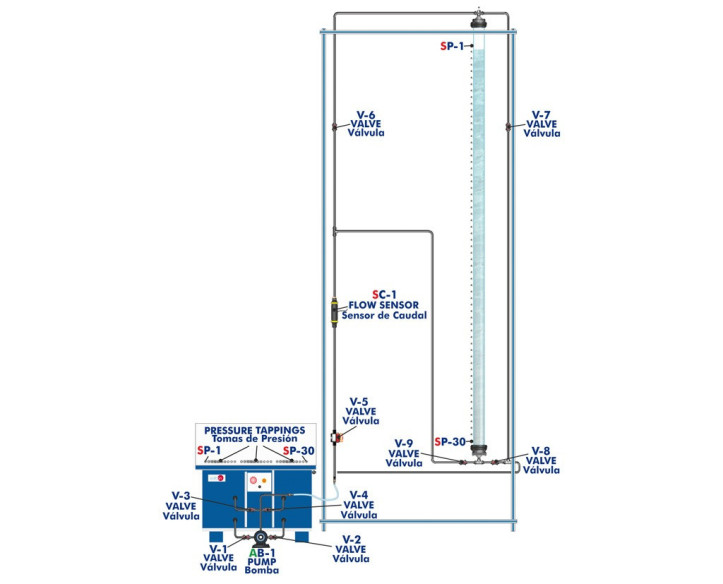

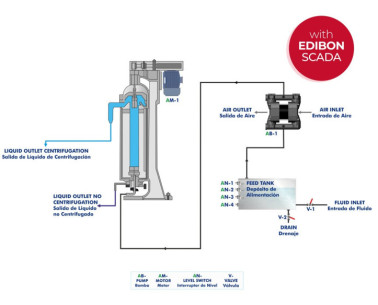

The pump takes raw water from one of the reservoirs of the unit and propels it towards the upper part of the column. That raw water passes through a diaphragm valve that controls the inlet flow rate of the column and a flow sensor that measures such flow rate.

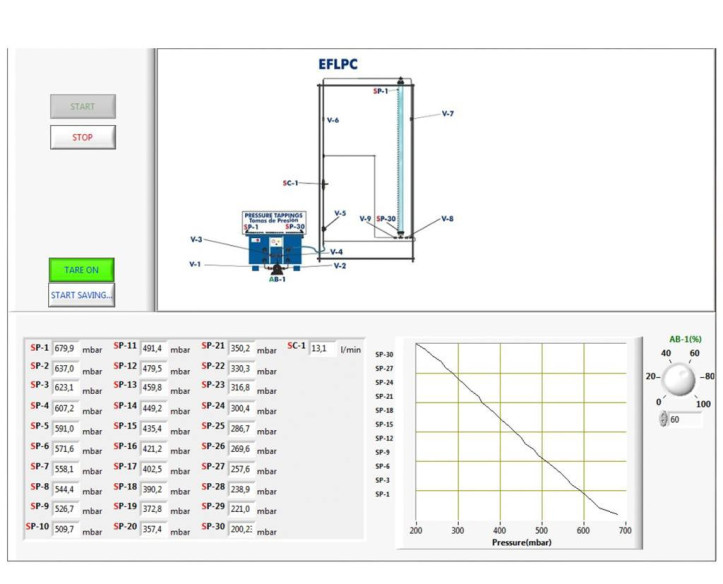

The liquid to be filtered goes down the column, crossing the filtering media settled as a bed and the pressure along the entire bed is measured at 30 points. It enables the measurement of the pressure drop that is visualized by the increase of the resistance that the filter opposes to the fluid.

The filtration process can be performed in closed or open circuit.

The solids settled in the filter can be removed by countercurrent washing.

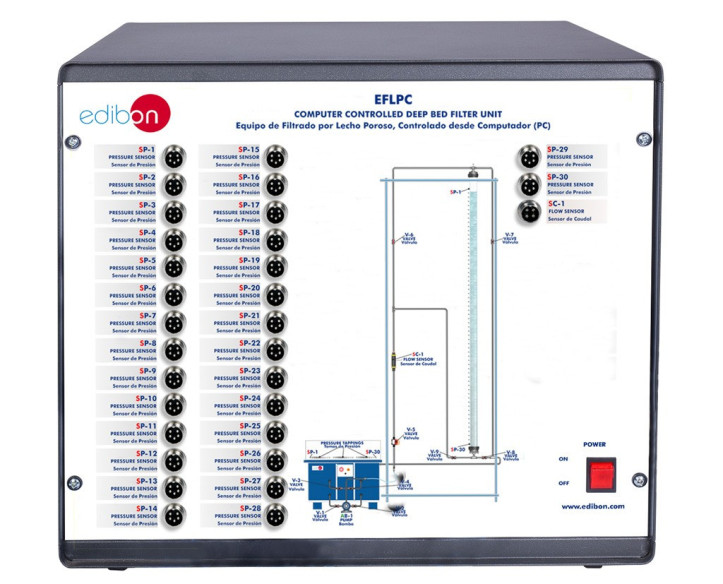

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Determination of the initial head loss of a deep bed.

- Evolution through time of the head loss of the deep bed.

- Measuring pressure drop profiles through the bed.

- Demonstration of reversed flow and backwashing fluidisation.

- Filtering in open and closed circuit.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

Additional practical possibilities:

- The column may be readily adapted for absorption and ion exchange studies.

- Measuring suspension concentration profiles through the filter bed.

- Filtration efficiency. Clarification.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EFLPC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EFLPC unit process.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

ERGÄNZENDE AUSRÜSTUNG

Halbkontinuierlicher Zentrifugalseparator von 60 l, gesteuert vom Computer (PC) und Touchscreen

Halbkontinuierlicher Zentrifugalseparator von 1000 l, gesteuert vom Computer (PC) und Touchscreen

Gerät für kontinuierliche und diskontinuierliche Filtration, computergesteuert (PC)

Gerät für kontinuierliche und diskontinuierliche Filtration

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Gerät für Tiefenbettsfiltration

Gerät für die Sedimentationsstudie

Sedimentationsbehälter, computergesteuert (PC)

Sedimentationsbehälter

Filter- und Drainagebehälter, computergesteuert (PC)

Filter- und Drainagebehälter

Gerät für Umkehrosmose/Ultrafiltration, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen