QCDIC Scheibenzentrifuge, computergesteuert (PC)

INNOVATIVE SYSTEME

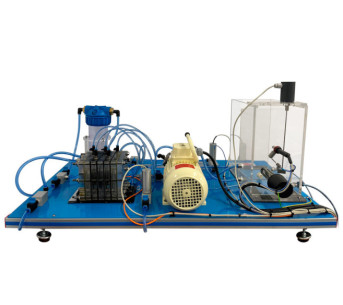

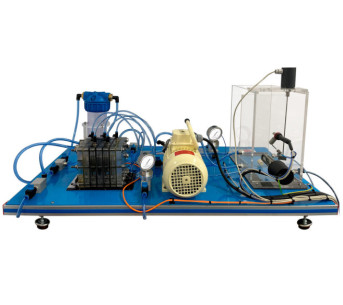

The Computer Controlled Disc Centrifuge, "QCDIC", has been designed by EDIBON to provide an experimental study of emulsion separation through centrifugal force.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

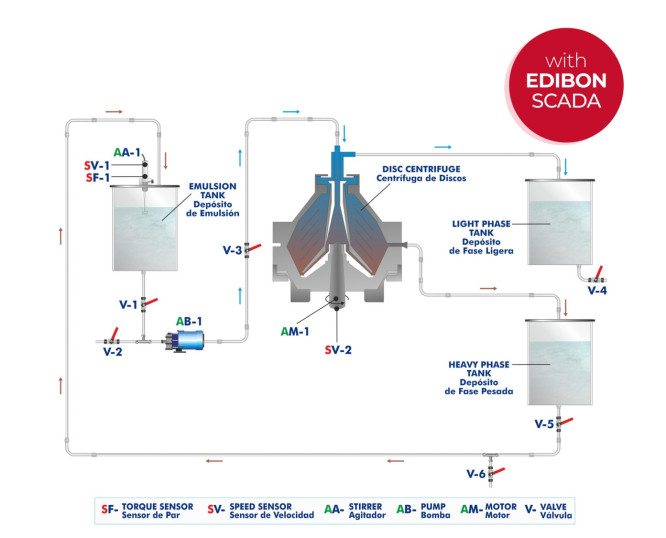

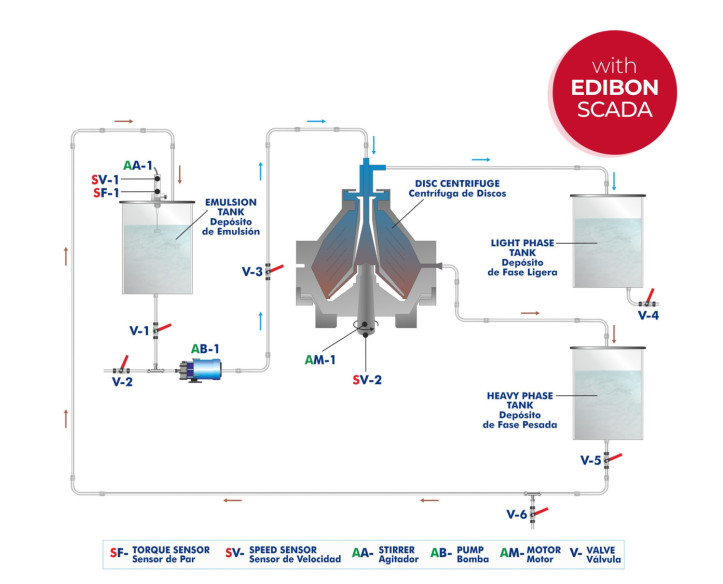

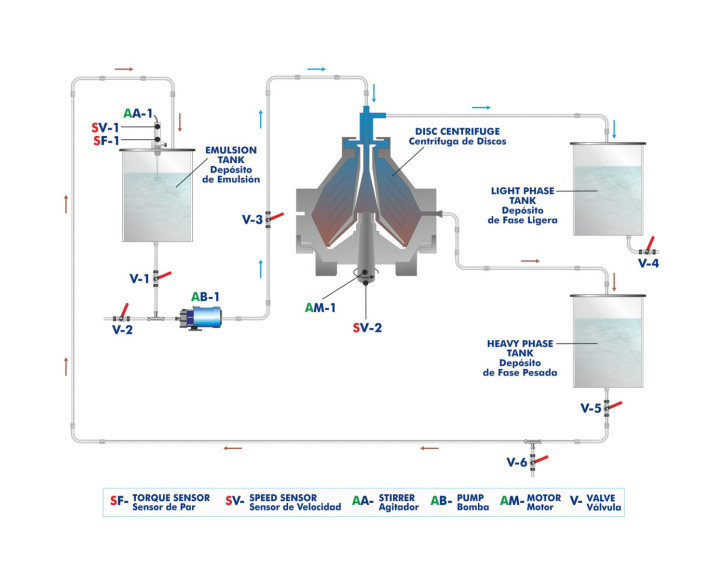

The Computer Controlled Disc Centrifuge, "QCDIC", designed by EDIBON, allows a complete study of the emulsion separation process by centrifugation, accurately reproducing the operating principles of industrial centrifuges. Its configuration integrates all the necessary elements to generate, feed, and separate a biphasic mixture. In this way, the unit enables practical analysis of accelerated sedimentation phenomena, the influence of angular velocity and feed flow rate, as well as the behavior of emulsions under a centrifugal field.

The process begins in the agitation tank, where two immiscible liquids, such as water and oil, are poured. A motor-driven agitator, controlled from the software, mixes the two phases uniformly and reproducibly. This actuator makes it possible to study how the agitation intensity affects emulsion stability, reducing the average droplet size and prolonging its homogeneity before the separation process.

Next, the emulsion is pumped by a computer-controlled pump to the disc centrifuge. This second actuator regulates the feed flow, allowing the analysis of the influence of flow rate and residence time on the separation efficiency.

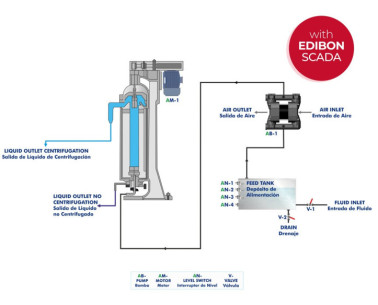

The emulsion enters the centrifuge from the top and is internally distributed through the bottom of the distributor. Inside, the inclined channels between the discs shorten the sedimentation path and accelerate the phase separation, causing the denser particles to move outward while the lighter ones remain near the center. The separated liquids flow through independent outlet channels and are collected in separate tanks. The disc centrifuge, driven by the third actuator of the unit, allows adjustment of the rotational speed from the computer to analyze its direct effect on separation efficiency.

Throughout the process, three sensors record in real time the fundamental variables: the rotational speed of the agitator, the centrifuge speed, and the torque. This continuous monitoring allows evaluation of the relationship between operating conditions and separation efficiency, providing accurate information on the dynamic behavior of the process.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the centrifugation process in disc centrifuges.

- Tune-up operations and control of a disc centrifuge.

- Observation of the influence of different stirrers in the produced emulsion.

- Tune-up of the unit with different initial proportions for the production of the emulsion.

- Study the influence of the initial flow in the separation result.

- Variation of the final separation depending on the stirrer mechanisms speed.

- Study of the concentration of the mix depending on the stirring time (requires photometer).

- Maintenance and cleaning functions.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QCDIC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QCDIC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Halbkontinuierlicher Zentrifugalseparator von 1000 l, gesteuert vom Computer (PC) und Touchscreen

Gerät für kontinuierliche und diskontinuierliche Filtration, computergesteuert (PC)

Gerät für kontinuierliche und diskontinuierliche Filtration

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Gerät für Tiefenbettsfiltration, computergesteuert (PC)

Gerät für Tiefenbettsfiltration

Gerät für die Sedimentationsstudie

Sedimentationsbehälter, computergesteuert (PC)

Sedimentationsbehälter

Filter- und Drainagebehälter, computergesteuert (PC)

Filter- und Drainagebehälter

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen