AEQC Käseherstellungswanne, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Cheese Vat, "AEQC", reproduces a small scale cheese production system to study the whole process in a practical way.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Cheese Vat, "AEQC", is a small scale unit designed to reproduce industrial cheese making operations.

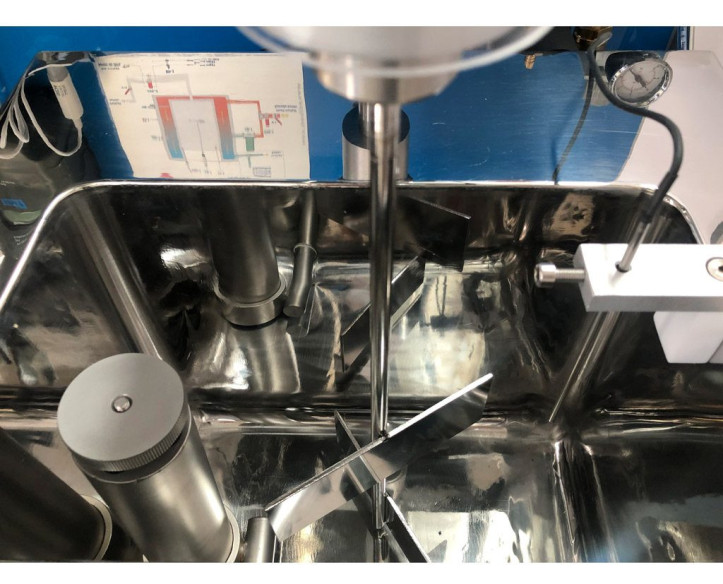

The main element is a hygienic vat made of stainless steel and mounted on a working frame.

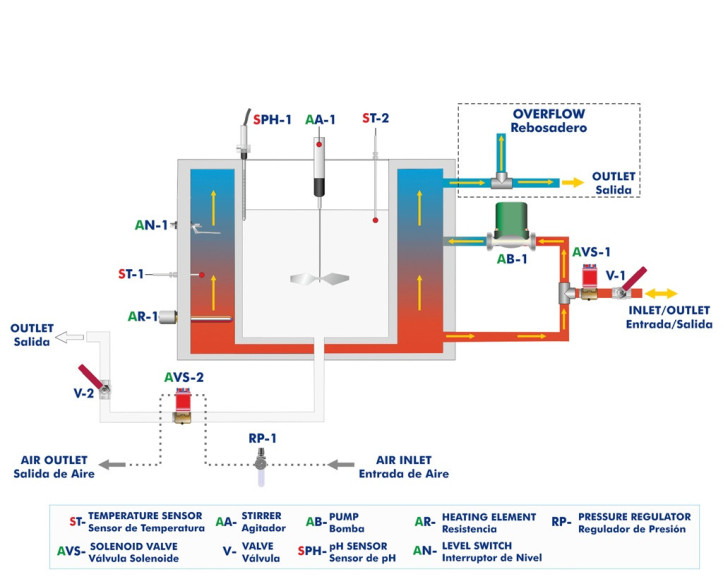

The vat has a jacket through which water heated by a heating element with thermostat flows. The water temperature is selected by a PID control and pumped by a variable speed circulation pump.

There is an agitator, which can be detached for easy cleaning. It consists of a variable speed motor that, by means of a duly protected coupling, drives the paddle agitator. It includes two types of stainless steel paddles.

Perforated stainless steel filter is placed at the outlet of the vat to separate the whey from the curd and drain the vat efficiently.

A temperature and a pH probe are immersed in the vat to monitor the process. The pH probe has a conical membrane that facilitates its introduction into semisolid products and allows a large contact area.

Both the heating jacket and the vat are automatically drained by solenoid valves.

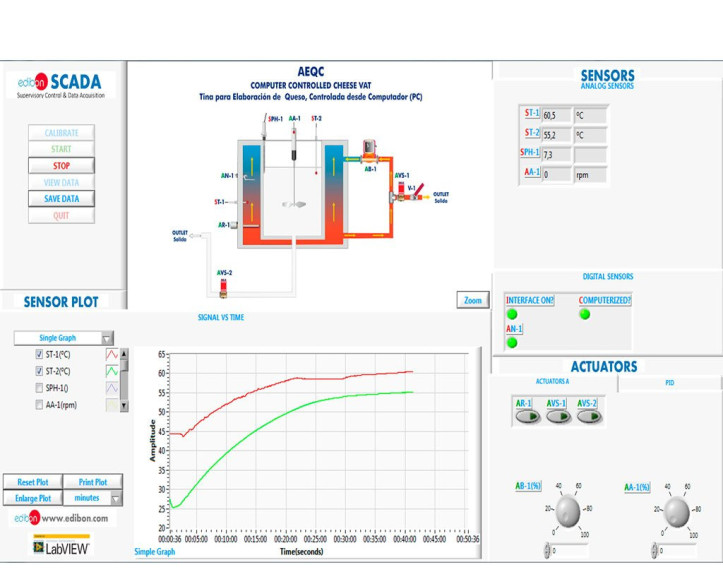

The Computer Controlled Cheese Vat, "AEQC", can be operated in manual or computerized way (performing the control and acquisition of data through the computer). The pump and the agitator speed, as well as the heating water temperature, are controlled. In addition, the pH and the temperature of the vat content and the agitator speed are monitored.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the cheese making process:

- Milk heating and agitation.

- Addition of starter culture and rennet.

- Coagulation.

- Curd cutting and heating.

- Precision curd heating and agitation to scald the curd.

- Curd settling.

- Whey draining.

- Curd milling.

- Addition of salt.

- Hard and soft cheese making.

- Study of the pressing process (the AEQC-A accessory is required).

- Acid testing (the AEQC-A accessory is required).

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously.To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the AEQC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the AEQC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

Niederländische Käseherstellungswanne (bis zu 50 Liter)

ERGÄNZENDE AUSRÜSTUNG

Didaktischer Rahmabscheider, computergesteuert (PC)

Didaktischer Rahmseparator

Gerät für Analoge Modulationen

Didaktisches Gerät zur Butterherstellung, computergesteuert (PC)

Gerät zur UHT, Computergesteuert (PC) und mit Touchscreen

Autonomer didaktischer Pasteurisierer, computergesteuert (PC)

Laborpasteurisator, computergesteuert (PC)

Didaktischer Gerinnungskessel, computergesteuert (PC)

Didaktische Käsepresse, computergesteuert (PC)

Niederländische Käseherstellungswanne (bis zu 50 Liter)

Didaktischer Joghurtinkubator, computergesteuert (PC)

Didaktischer Quarkbereiter, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen