EESTC Gerät für Thermische Solarenergie, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Thermal Solar Energy Unit, "EESTC", is a system that transforms solar energy into usable thermal energy. It uses the thermosiphon solar system to heat water or the traditional pumping system.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

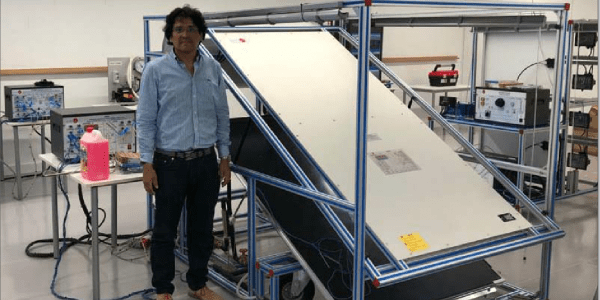

The Computer Controlled Thermal Solar Energy Unit, "EESTC", is a system that transforms solar energy into usable thermal energy. It uses the thermosiphon solar system to heat water or the traditional pumping system. In both cases, the absorbed thermal energy is given by the simulated solar radiation, in our case, it is done using a panel with powerful luminous sources.

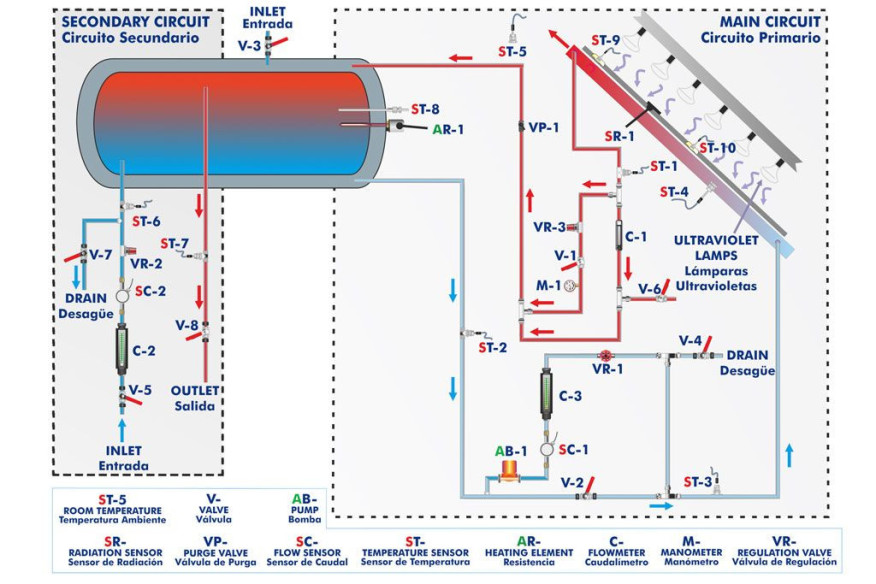

The EESTC unit mainly consists of the following elements:

- Thermal solar collector.

- Accumulator tank.

- Solar simulator.

- Pumping system.

The solar collector is mounted on an aluminum frame and the fluid (water) flows through cooper tubes. It has been developed in such a way that the geometrical shape of the surface allows the most efficient absorption.

The accumulator tank is protected with an anti-corrosive material. It has a computer controlled heating element with a safety device to prevent over-temperatures.

Lamps of the solar simulator emit radiation similar to the sun radiation, which is measured by a radiation sensor. The light is converted into heat in the solar collector and transferred to the heat transfer fluid. Three different configurations can be simulated with the solar simulator: all the lamps are turned on, half of the lamps are turned on in zigzag, or only one lamp is turned on.

Besides, the unit includes a computer controlled pump to perform a forced convection of the heat transfer fluid through the accumulator tank.

The unit is fitted with sensors and meters to record the relevant parameters (temperature, flow and radiation) and are included safety valves for overpressure protection.

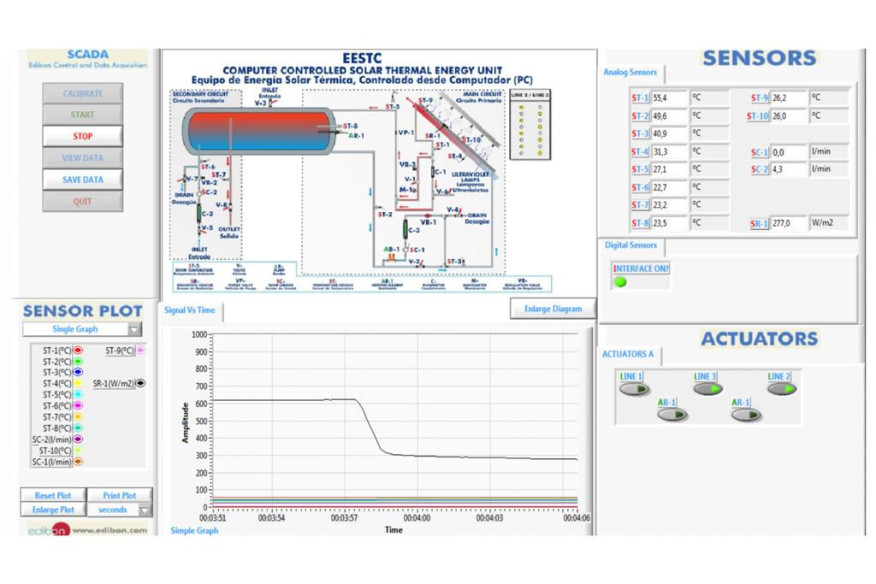

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the thermosiphon operation.

- Study of the luminosity profile of the lamps.

- Study of the efficiency of the solar panel.

- Study of the influence of the tilt angle of the lamps panel on the unit efficiency.

- Study of relation between the flow and the temperature.

- Study of energy balance of the solar collector.

- Study of energy balance of the accumulator tank.

- Determination of the experimental efficiency.

- Study of the influence of the angle of incidence on the temperature.

- Sensors calibration.

- Flowmeter calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EESTC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EESTC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Gerät für Thermische Solarenergie

Grundgerät für Solarthermie

Solarenergie-Kollektor, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen