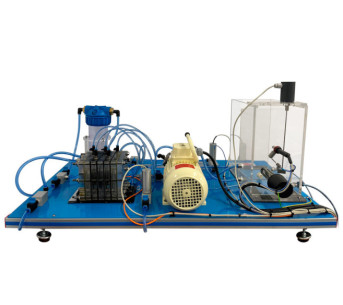

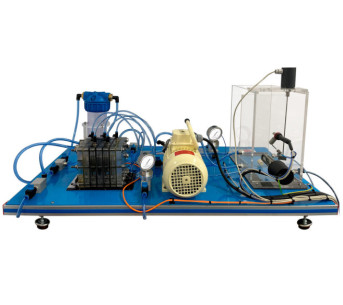

AFPMC Platten- und Rahmenfilterpresse, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Plate and Frame Filter Press, "AFPMC", has been designed to demonstrate the filtration and clarification processes suitable for chemical, pharmaceutical, food and beverage industries, etc.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Plate and Frame Filter Press, "AFPMC", has been designed to study the filtration and clarification processes using a filter press in which the number of frames and the type of filter cloths can change.

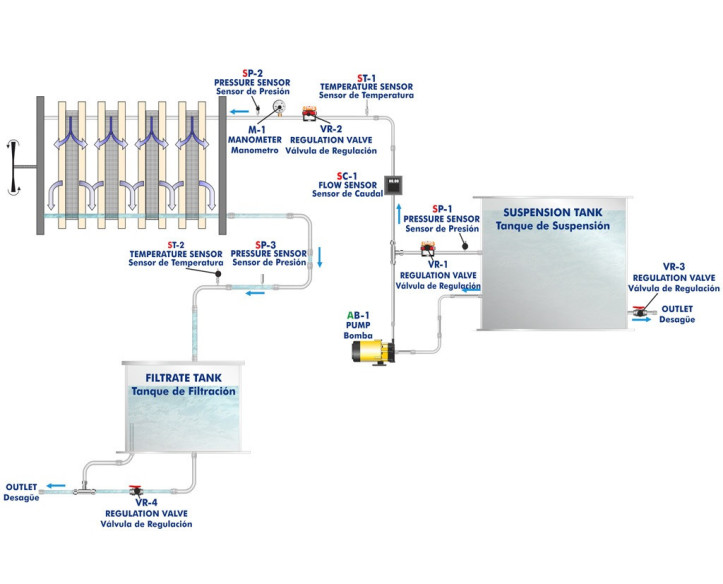

A suspension is prepared in a feed tank and is transferred through a computer controlled centrifugal pump into the plate and frame press. This pump ensures that the solids remain suspended and do not settle.

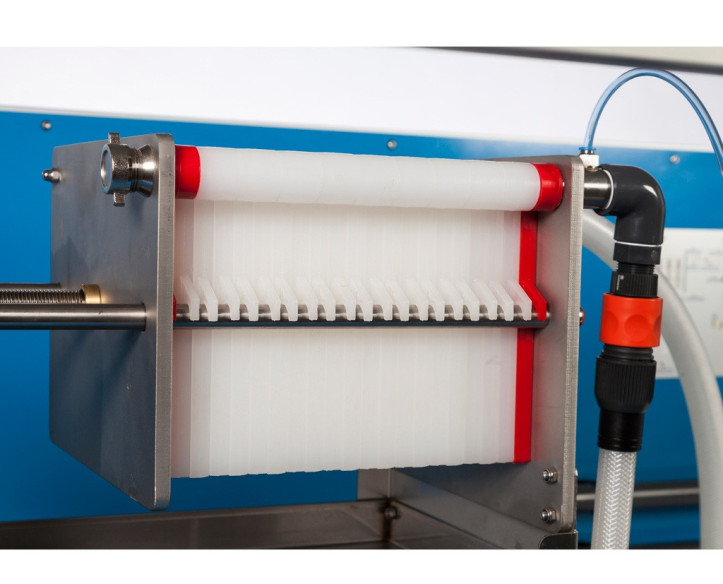

The filter plates are grooved and covered over with filter cloths. Filter cloth (or filter media) retains the solid particles of the suspension, which fills the frame plates, whilst the filtrate passes through the filter media or filter cloth. The filtrate flows through the collecting pipe and is collected in the filtrate tank. The solid material is separated off from the filter cloth, where it forms a growing filter cake. The unit includes several types of filter cloths.

The suspension passes through three pressure sensors and one flow sensor on its way. Besides, the initial temperature of the suspension and the final temperature of the filtrate can be recorded with two temperature sensors.

A turbidity meter allows the solid concentration of the filtrate to be determined.

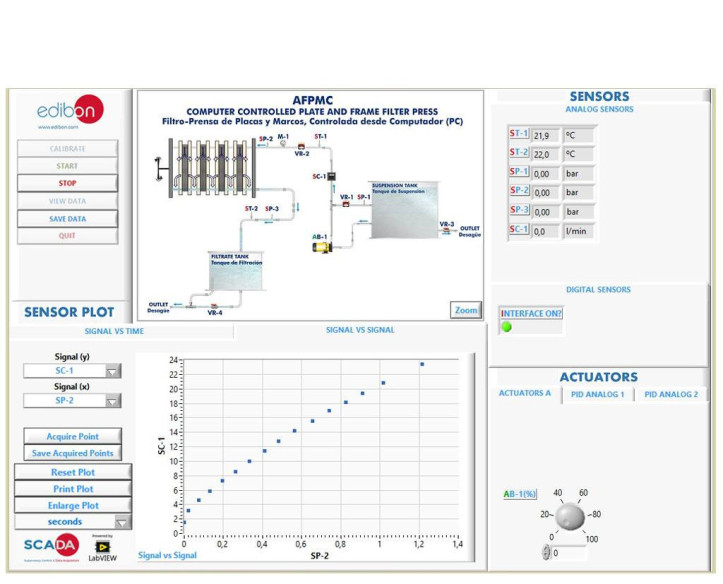

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Learning the fundamental principle and operation method of a plate and frame filter press.

- Study of filtration and clarification processes.

- Demonstration of pre-coat filtration.

- Production of a suspension.

- Formation of a cake.

- Fundamentals of cake filtration. Demonstration of Darcy’s Law.

- Turbidity versus concentration calibration straight line.

- Study of the plate and frame filter press at constant pressure.

- Study of the plate and frame filter press at constant flow.

- Variation in time of filtrate quantity and solid concentration in filtrate.

- Mass of filter cake in function of filtrate quantity.

- Determination of medium and cake resistance.

- Filter cake washing and dewatering.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Sensors calibration.

- Influence of the number of frames and filters in the filtration process.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the AFPMC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the AFPMC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

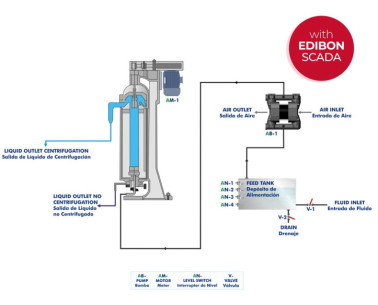

Halbkontinuierlicher Zentrifugalseparator von 1000 l, gesteuert vom Computer (PC) und Touchscreen

Gerät für kontinuierliche und diskontinuierliche Filtration, computergesteuert (PC)

Gerät für kontinuierliche und diskontinuierliche Filtration

Gerät für Tiefenbettsfiltration, computergesteuert (PC)

Gerät für Tiefenbettsfiltration

Gerät für die Sedimentationsstudie

Sedimentationsbehälter, computergesteuert (PC)

Sedimentationsbehälter

Filter- und Drainagebehälter, computergesteuert (PC)

Filter- und Drainagebehälter

Gerät für Umkehrosmose/Ultrafiltration, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen