PDSC Sedimentationsbehälter, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Sedimentation Tank, "PDSC", is a teaching unit, designed by EDIBON, to demonstrate the sedimentation process and to familiarize with the settling principle of discrete particles settling into a tank.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

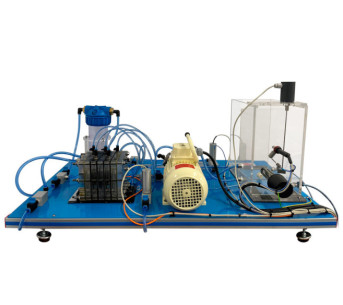

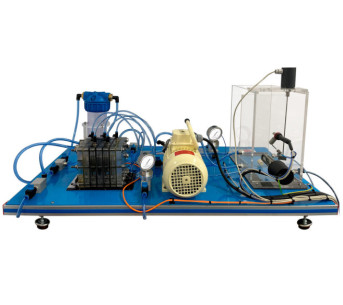

The Computer Controlled Sedimentation Tank, "PDSC", is a teaching unit, designed by EDIBON, to demonstrate the sedimentation process and to familiarize with the settling principle of discrete particles settling into a tank. It will also allow to study the hydraulic characteristics of a rectangular sedimentation tank which works in continuous.

As it is a laboratory unit, it allows to obtain valid conclusions about its operation and to apply them to the operation of a real scale unit.

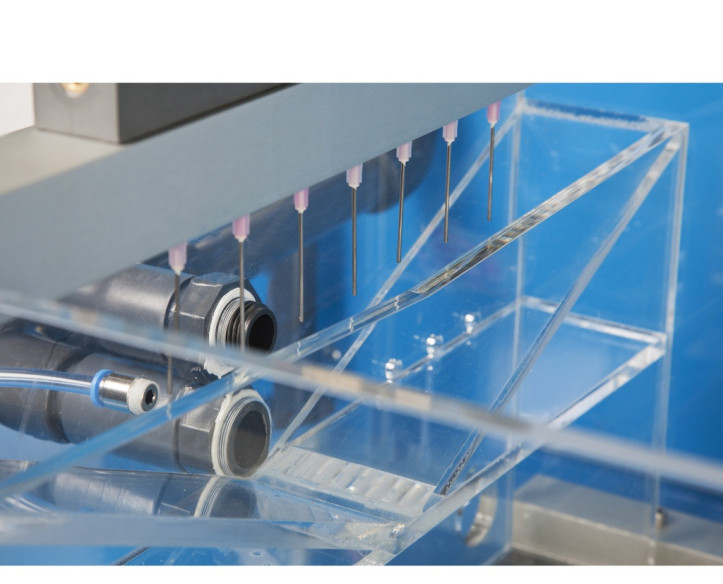

The great advantage of the "PDSC" unit is that its sedimentation tank is made of transparent material. So, this allows the student to understand the sedimentation principles. This fact allows to carry out several practices, as well as to make easier the comprehension of the different variables influence on the process.

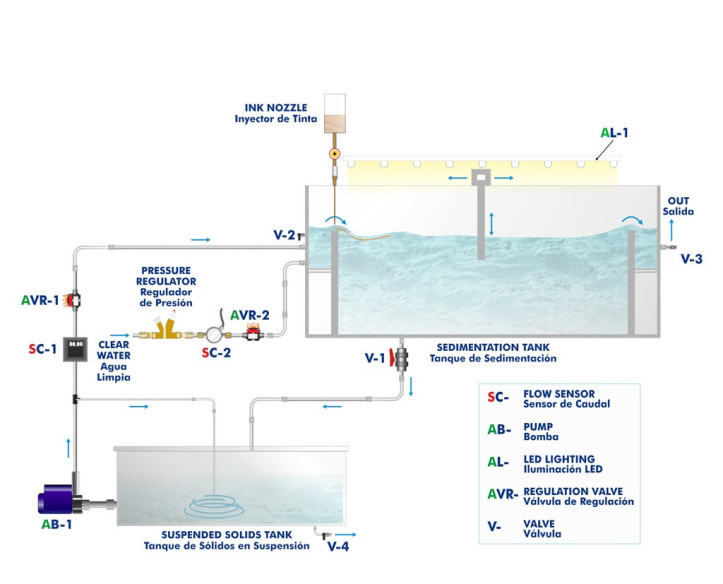

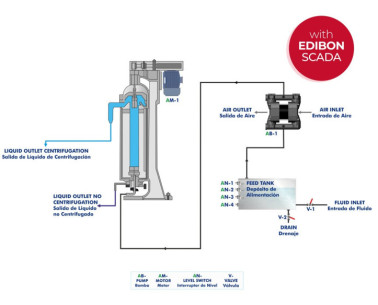

The practical exercises start preparing a suspension in the suspension tank, placed at the unit lower part. A computer controlled pump drives the suspension from the suspension tank to the sedimentation tank with a flow selected by using a computer controlled regulation valve and measured with a flow sensor. This suspension is mixed with clean water at the sedimentation tank inlet. The clean water flow is controlled by using a computer controlled regulation valve and flow sensor.

Once the fluids are mixed, the current is passed into the sedimentation tank through the inlet weir. Here, the solids in suspension settle at the bottom.

The clarified water outlet is done through the outlet overflow located at the opposite side of the tank. There are sampling valves both in the inlet overflow and outlet overflow that allow the student to analyze the water quality.

The unit has a dye injection and tracer system, which allows to study the fluid current lines into the sedimentation tank.

It also has two adjustable in height baffle plates, which can be placed at any point of the tank length, what makes easier for the student the possibility of changing the flow lines direction and its study.

There are led lights at the upper side of the sedimentation tank to facilitate the observation of the flow conditions.

As support to carry out the practical exercises, the following accessories are supplied: two Imhoff cones and a graduated test tube of 1 l.

The Lamellar Sedimentation Optimization Accessory, "PDS/LSO", enhances efficiency in water clarification and treatment processes. Its design with inclined lamellar plates increases the sedimentation surface, accelerating the separation of suspended solids and reducing the required space.

If desired, the Lamellar Sedimentation Optimization Accessory, "PDS/LSO" can be used to study its impact on the sedimentation process. The flow passes through the plates arranged in a zigzag weir configuration, improving the efficiency of suspended particle separation and optimizing the performance of the clarification process.

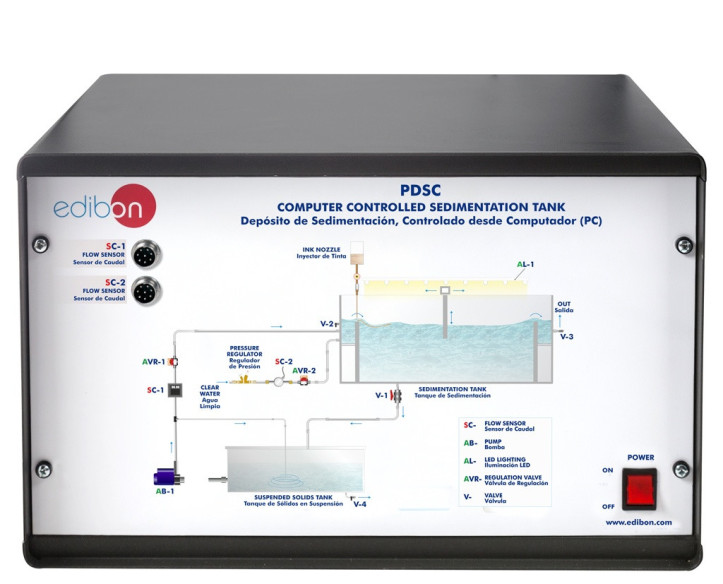

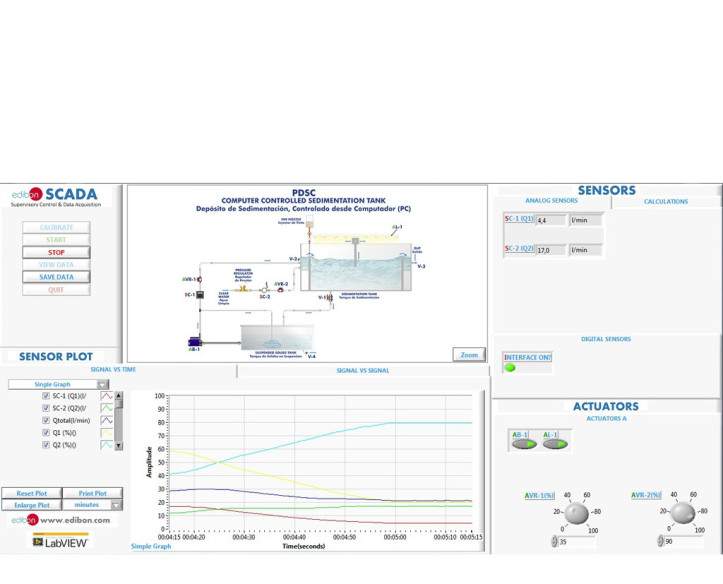

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Main elements of a system designed to separate solids in a sedimentation tank.

- Influence of the concentration of suspended solids on the separation process.

- Influence of the supply flow on the separation process.

- Influence of the position of baffle plates on the separation process.

- Determination of the surface hydraulic load for different concentration of solids in suspension.

- Research about the flow conditions, determination of flow short-circuits and dead spaces using an ink tracer.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Comparison of real flow regimes with idealised flow models.

- Sensors calibration.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PDSC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PDSC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

ERGÄNZENDE AUSRÜSTUNG

Halbkontinuierlicher Zentrifugalseparator von 60 l, gesteuert vom Computer (PC) und Touchscreen

Halbkontinuierlicher Zentrifugalseparator von 1000 l, gesteuert vom Computer (PC) und Touchscreen

Gerät für kontinuierliche und diskontinuierliche Filtration, computergesteuert (PC)

Gerät für kontinuierliche und diskontinuierliche Filtration

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Gerät für Tiefenbettsfiltration, computergesteuert (PC)

Gerät für Tiefenbettsfiltration

Gerät für die Sedimentationsstudie

Sedimentationsbehälter

Filter- und Drainagebehälter, computergesteuert (PC)

Filter- und Drainagebehälter

Gerät für Umkehrosmose/Ultrafiltration, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen