VPMC Mehrzweckverarbeitungsbehälter, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Multipurpose Processing Vessel, "VPMC", developed by EDIBON, is a type batch equipment, suitable to demonstrate the different mixing processes in the alimentary industry.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Multipurpose Processing Vessel, "VPMC", has all the necessary to:

- Mix.

- Emulsify.

- Heat.

- Pasteurise.

- Incubate.

- Cool.

- Chill.

- Cure.

As well as the preparation of food products for further processing, it allows to produce finished products in batch sizes from 5 up to 30 lmaximum.

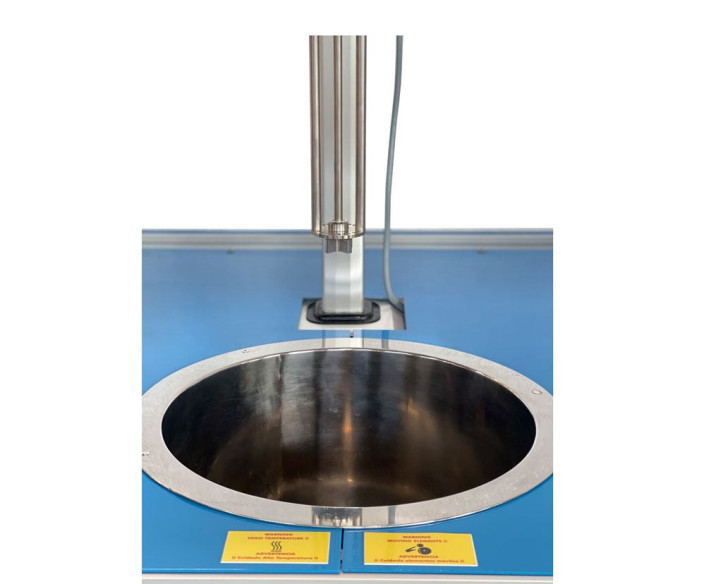

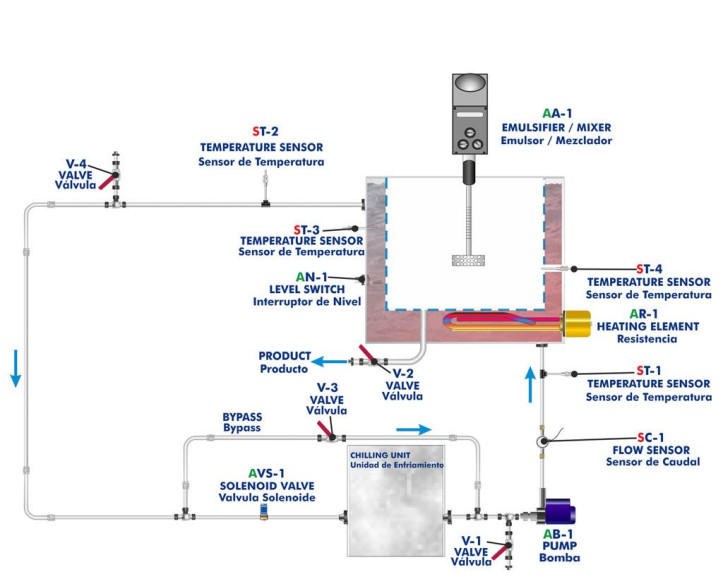

This unit consists of a cylindrical-shaped jacketed vessel, into which different tests are carried out. Outside of the vessel, a water bath, whose temperature is controlled, is disposed. To heat the vessel content, an electric heating element is mounted. When a chilling of the products in the vessel is required there is a chilling unit, which supplies water in a continuous way to the vessel jacket.

The mixing stage is carried out by a mixer, which has a high speed motor and with an emulsifier/mixer head adjustable in height. Four different type of heads, suitable for different elaboration processes, are supplied.

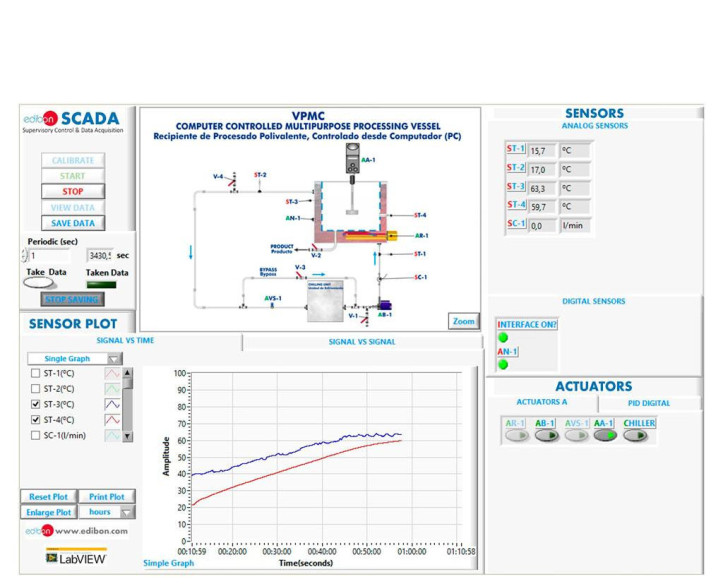

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of different process, with their adequate instrumentation, using heating and cooling systems.

- General emulsion study.

- Mayonnaise production.

- Yogurt production.

- Batch pasteurization of milk.

- Processing of fermented milk products.

- Preparation and curing of ice cream mix.

- Preparation of margarine and soft spread emulsions.

- Heat transfer measurement.

- Heat transfer calculations.

- Study of general heating, cooling and chilling.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the VPMC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the VPMC unit rocess.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Sprühtrockner, computergesteuert (PC)

Sprühtrockner

Gerät für Sprühtrocknung und -kühlung, computergesteuert (PC)

Gerät für Umkehrosmose/Ultrafiltration, computergesteuert (PC)

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Gerät zur Hydrierung, computergesteuert (PC)

Gerät zur Desodorierung, Computergesteuert (PC)

Fortschrittliches Gerät zur Desodorierung, Computergesteuert (PC)

Anlage zur kontinuierlichen Herstellung von Öl, computergesteuert (PC)

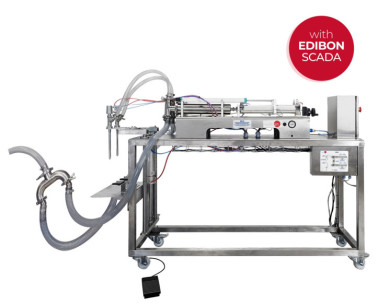

Didaktisches Gerät für die Abfüllung von Flüssigkeiten, computergesteuert (PC)

Didaktisches Gerät für die Verpackung von Feststoffen, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen