DSNC Didaktischer Rahmabscheider, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Teaching Cream Separator, "DSNC", designed by EDIBON, is a unit that provides a practical training in the separation technique of the different phases of a liquid, according to the density of each part.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Teaching Cream Separator, "DSNC", allows the study of the separation of a dense phase liquid from a lighter phase liquid, in particular the separation of the cream from the milk in a disk stack centrifuge.

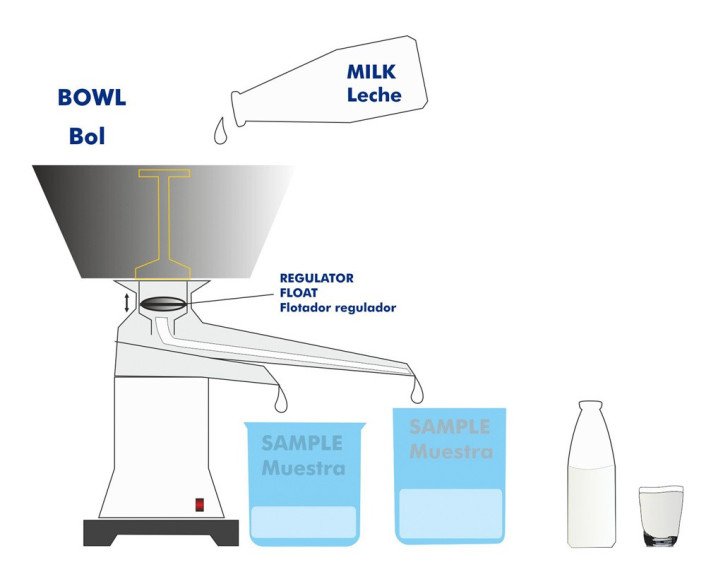

The system is mounted on a table base on which the integral elements of the unit are located.

The milk supply tank is located over the centrifuge and can be filled in continuously.

The separating bucket consists of a vertical rotation axis and discs or conical plates. They are arranged one on top of another in an inverted manner and separated by very little distance. In addition, the discs have small holes that allow the flow of material through them.

This set of discs is surrounded by a casing and sealed by a rubber gasket to avoid possible losses. All these elements are contained in a polypropylene bucket or vessel that includes two outlet ducts, one for the cream and another for the skimmed milk.

The motor is directly coupled to the separator vessel and vertically mounted in a casing. It makes the plates rotate at high speed and, therefore, it is the element that creates the centrifugal force.

Besides, the unit has a control panel that contains the speed regulator. It allows to control and vary the turning speed of the motor, so that the density of the cream to be obtained is controlled.

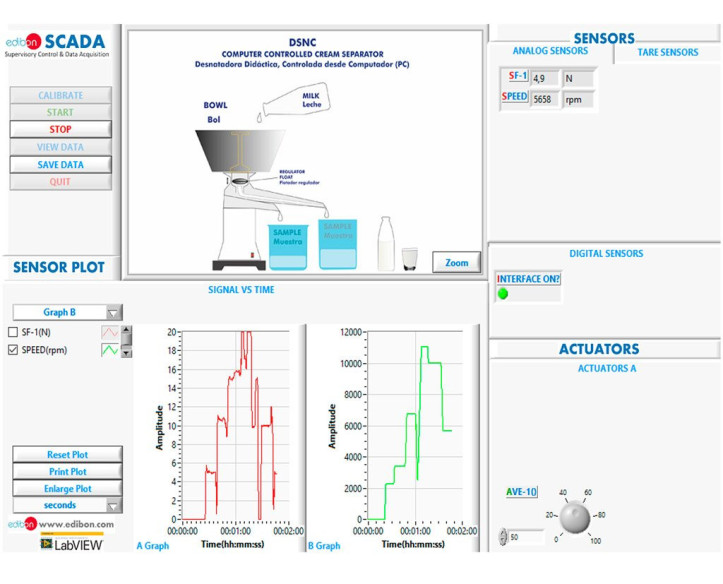

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the separation of different density liquids.

- Demonstration of the effect of the temperature in the separating process.

- Demonstration of the effect of the speed in the separating process.

- Production of different types of cream by using milks with different greasy matter contents, (11 % to 55 %).

- Production of a range of skimmed milks with different contents of greasy matter.

- To show the importance of cleanness and hygiene in food processing.

- Understanding the operation mode of this type of centrifuge, using instructive diagrams and ease of strip down the component parts.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the DSNC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the DSNC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

ERGÄNZENDE AUSRÜSTUNG

Didaktischer Rahmseparator

Gerät für Analoge Modulationen

Didaktisches Gerät zur Butterherstellung, computergesteuert (PC)

Gerät zur UHT, Computergesteuert (PC) und mit Touchscreen

Autonomer didaktischer Pasteurisierer, computergesteuert (PC)

Laborpasteurisator, computergesteuert (PC)

Didaktischer Gerinnungskessel, computergesteuert (PC)

Didaktische Käsepresse, computergesteuert (PC)

Niederländische Käseherstellungswanne (bis zu 50 Liter)

Didaktischer Joghurtinkubator, computergesteuert (PC)

Didaktischer Quarkbereiter, computergesteuert (PC)

Käseherstellungswanne, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen