TRCC Gerät für Kühlsysteme mit offenem Kompressor, computergesteuert (PC)

INNOVATIVE SYSTEME

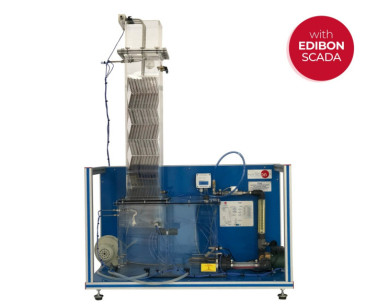

The Computer Controlled Refrigeration Unit with Open Compressor, "TRCC", has been designed to carry out basic tests for the study of a vapor-compression refrigeration cycle with an open compressor driven by an electric motor.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

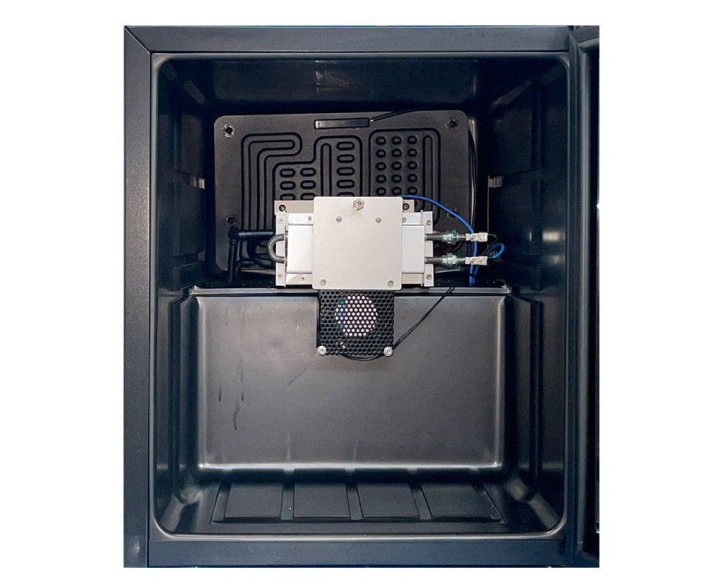

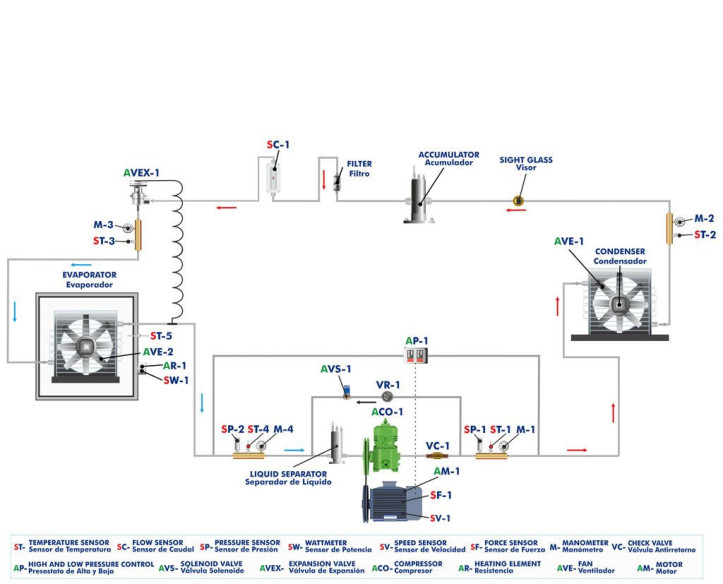

The Computer Controlled Refrigeration Unit with Open Compressor is arranged in a clear way and represents a typical compression refrigeration system with open compressor:

The main elements of the unit are:

- Open compressor activated by an electric motor.

- Condenser with fan.

- Expansion valve.

- Evaporator with fan.

The low pressure saturated refrigerant vapor, coming from the evaporator, is compressed in an open compressor driven by an electric motor though a V-belt. Therefore, its pressure increases, involving a temperature increment too. It causes the transformation of the workingfluid from saturated steam to superheated steam.

The number of revolutions of the electric motor is adjustable, allowing the study of the cycle at different degrees of compression. In addition, the electric motor is suspended as a pendulum, having a force sensor to determine the torque.

The high pressure superheated steam from the compressor flows inside an air condenser, where the working fluid, in vapor phase, transfers heat to atmospheric air (hot source) whilepassing through the tubes. Therefore, the working fluid undergoes a phase change, to liquid state, through a condensation process.

At the outlet of the condenser the cooling liquid passes through an expansion valve , whose function is to control the flow of refrigerant in liquid state entering the evaporator.

The low pressure cooling liquid coming from the expansion valve is introduced into an evaporator, where there is a heat transfer from the coldsource (atmospheric air) to the cooling liquid, producing a phase change of the working fluid until it becomes saturated steam. This process is isobaric (P = constant).The evaporator is located inside a refrigeration chamber, which includes a heating element with adjustable power to simulate a change in the conditions of the system and create different thermal loads.

The temperature and pressure can also be measured in the circuit at key points of the cycle. Besides, the circuit includes a sight glass to observe the state of the working fluid, a filter, a storage vessel to ensure a proper flow of refrigerant in the circuit, and a liquid separator to prevent liquid from entering the compressor.

As a safety measure, the circuit includes a combined high and low pressure switch and a bypass circuit with solenoid valve.

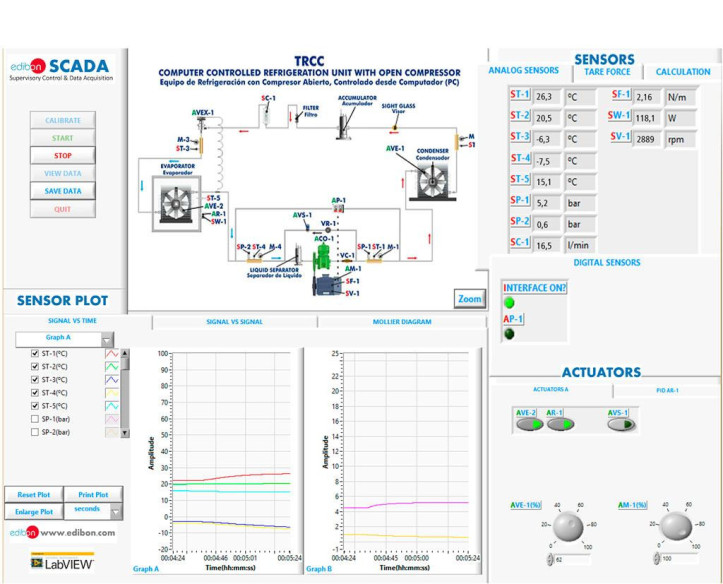

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the fundamentals of a refrigeration system.

- Study of the operation, structure and elements of a vaporcompression refrigeration system.

- Study of an open compressor: number of revolutions and torque.

- Study of the activation of an open compressor using an electric motor.

- Influence of the compressor flow rate in the refrigeration circuit.

- Influence of the evaporator temperature change in the refrigeration circuit.

- Determination of the refrigeration system features: performance of the compressor, refrigeration power, compressor power, compression ratio, volumetric efficiency and representation of the thermodynamic cycle in a log p-h diagram.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Study of the evaporator, condenser, expansion valve and pressure switch.

- Measurement of the mechanical power of the electric motor.

- Relationship between pressure and temperature.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TRCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TRCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Tisch-Kühlturm

Gerät zur Demonstration des Kühlzyklus, computergesteuert (PC)

Gerät zur Demonstration des Kühlzyklus

Gerät für Absorptionskühlung, computergesteuert (PC)

Gerät für Absorptionskühlung

Leistungsregelung und Fehlerüberwachung in Kälteanlagen, computergesteuert (PC)

Gerät für Kühlsysteme mit Vortex-Röhren, computergesteuert (PC)

Thermoelektrische Wärmepumpe, computergesteuert (PC)

Gerät für einen einfachen Kältekreislauf mit Kompression

Wärmepumpe + Klimaanlage + Umkehrkühlung mit 2 Kondensatoren und 2 Verdampfern (Wasser/Luft), computergesteuert

Wärmepumpe + Klimaanlage + Umkehrkühlung mit 2 Kondensatoren und 2 Verdampfern (Wasser/Luft)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen