PLGC Gaswäscheranlage, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Gas Washing Processing Plant, "PLGC", designed by EDIBON, allows to evaluate the operation of a gas washing plant, analyzing its efficiency.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

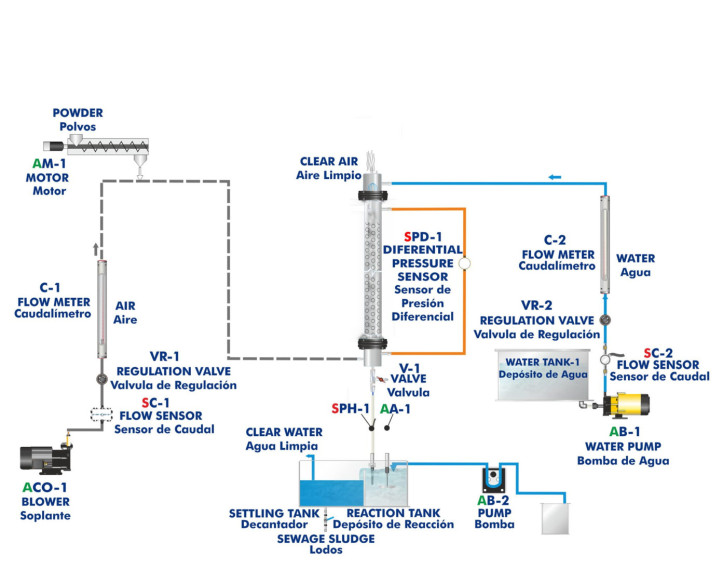

The Computer Controlled Gas Washing Processing Plant, "PLGC", designed by EDIBON, has a water feed tank, from which and by means of a water pump, the water is pumped to the upper part of a column. The solids are added by means of a solid dosing system to the air current, which is introduced in the column by its lower part. The water pumped to the upper part of the column is pulverized, by means of showers, to drag the added solids in the air current.

This column has Raschig rings, which increase the surface of interchange between the water and the polluted air current.

The plant has two flow sensor and flowmeters: one to measure the water flow and the other one to measure the air current.

The water current that flows through the bottom of the column goes to a reaction tank. This tank has an stirring system and a pH sensor.

The current is mixed with the flocculant. It will produce the later sedimentation of particles and their decantation. Thus, we can separate a sludge current and a clean current.

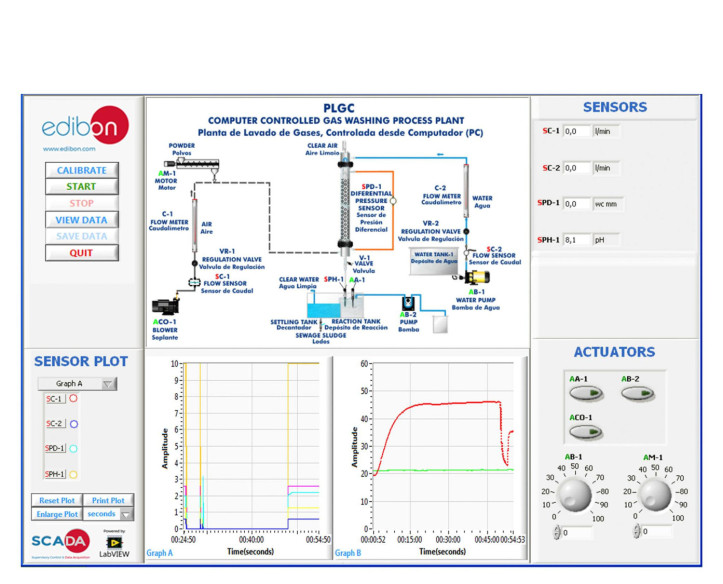

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Familiarization with a gas washing plant.

- Study of the water flow influence on the gas washing plant efficiency.

- Study of the air flow influence on the gas washing plant efficiency.

- Study of the introduced dust mass influence on the gas washing plant efficiency.

- Determination of the gas washing plant efficiency related to the quantity of solids introduced into the air current with the quantity of sedimented solids.

- Best quantity of floculant to produce the dust particles precipitation.

- Determination of the best pH for the solid particles sedimentation which go together with the water.

- Study of the best pH to obtain biggest purity in settled water.

- Study of the floculant presence influence on the pH variation in the reaction-settling tank.

- Pressure losses in the gas washing plant.

- Sensors Calibration

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PLGC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PLGC unit process.

ERGÄNZENDE AUSRÜSTUNG

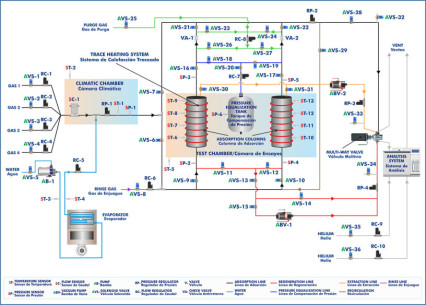

Gerät für Gasabsorptionssäule

Gerät für Gasabsorption mit Doppelsäule

Gerät für Dünnschicht-Gasabsorptionssäule, computergesteuert (PC)

Gerät für Laborversuche mit Druckwechseladsorption

Gerät für Adsorption mit festem Bett, computergesteuert (PC)

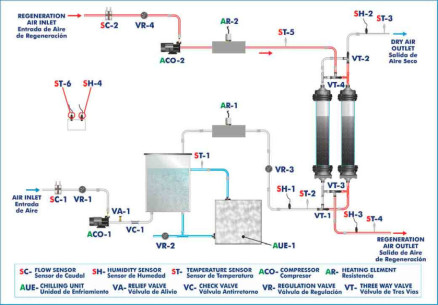

Gerät zur Lufttrocknung durch Adsorption, computergesteuert (PC)

Gerät für das Studium des Flusses in Füllstoffsäulen, computergesteuert (PC)

Gerät für Adsorption, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen