EDPAC Evaporador de Película Ascendente de Duplo Efeito, Controlado por Computador (PC)

SISTEMAS INOVADORES

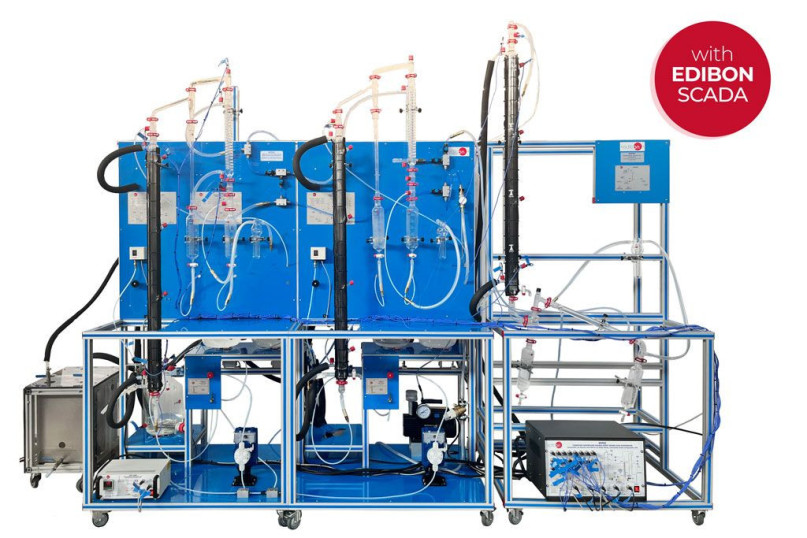

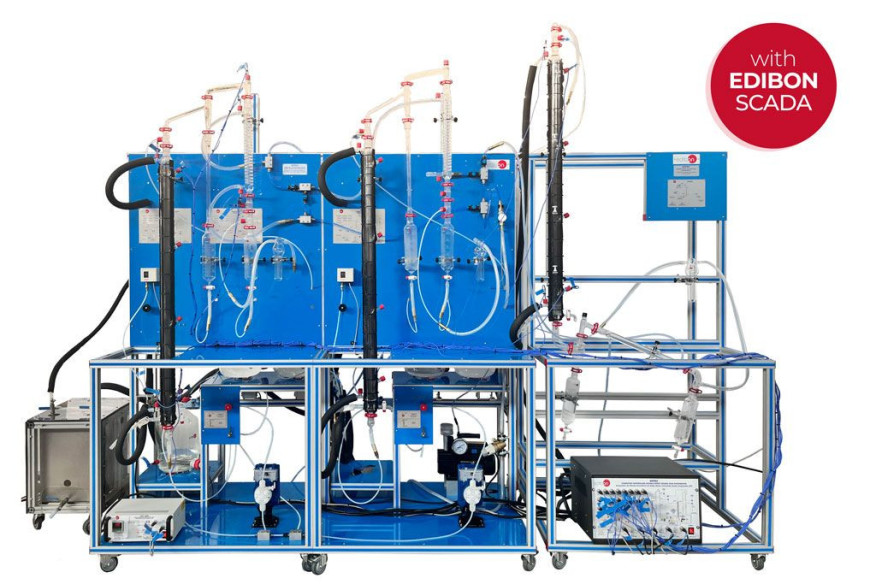

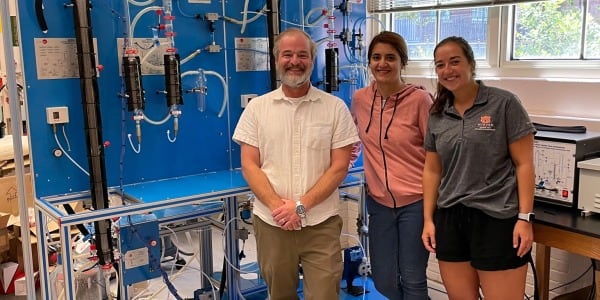

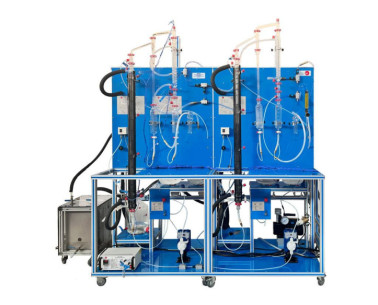

The Computer Controlled Double Effect Rising Film Evaporator, "EDPAC", designed by EDIBON, allows to observe and control a serial, parallel or double effect evaporation process.

Expansões

LABORATÓRIOS

NOTÍCIAS RELACIONADAS

Descrição Geral

The Computer Controlled Double Effect Rising Film Evaporator, "EDPAC", designed by EDIBON, allows to observe and control a serial, parallel or double effect evaporation process.

The unit consists of two evaporators with a single glass tube, allowing the student to observe all the processes that take place in the unit.

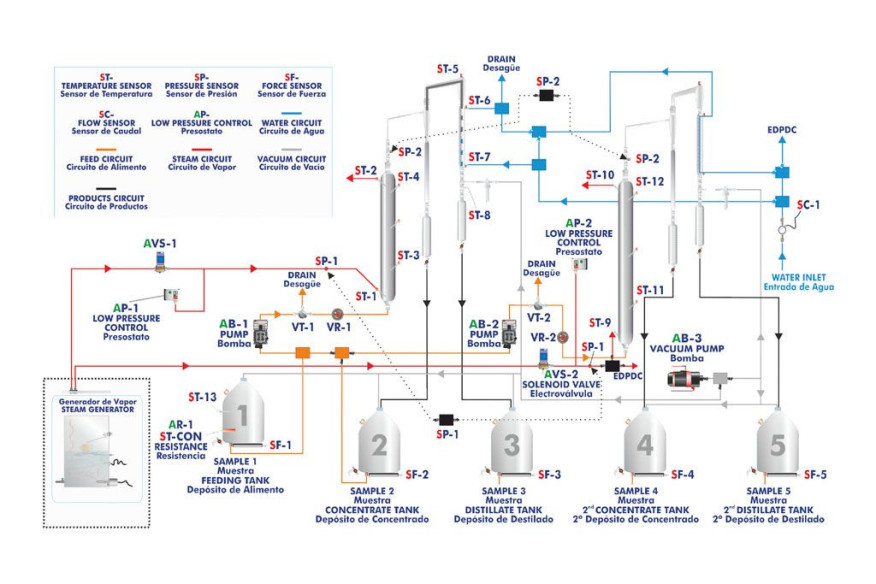

The solution to be concentrated enters the evaporator and, as it flows along the tube, it is progressively evaporated since an annular flow or rising film flow is generated internally, keeping that film thanks to the friction induced by the vapour nucleus, which moves at high speed with regard to the liquid film. The supply enters the rising tube in liquid state for a short distance, receiving heat from the steam.

Steam introduced in the first evaporator can be introduced again in the second evaporator (serial operation mode) or either two different steam flows can be introduced (parallel operation mode).

The unit also allows the steam generated in the first evaporator to be introduced as heating medium in the second evaporator and the concentrated product obtained can be used as supply for the second column. Thus, one of the main premises of a double effect evaporator, which is the economy of the heat employed, can be evaluated.

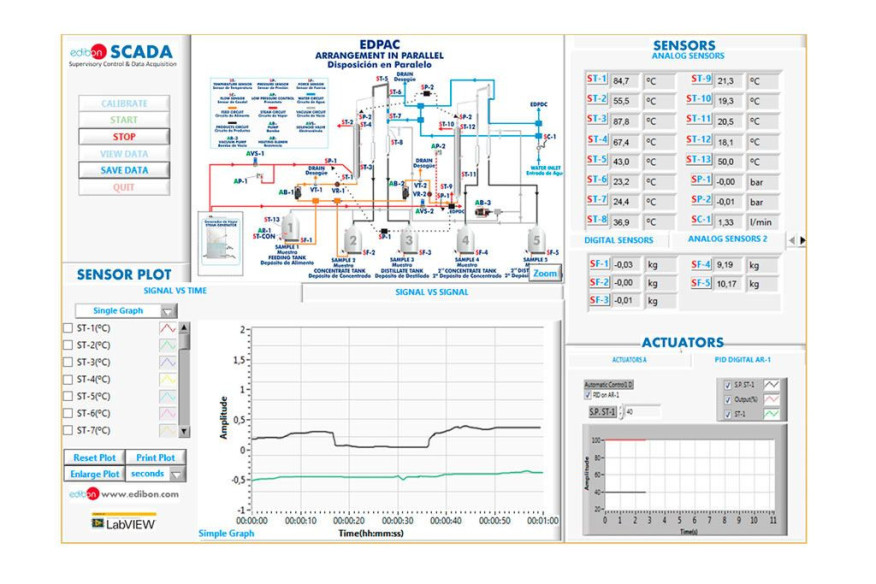

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

EXERCÍCIOS E PRÁTICAS GUIADAS

EXERCÍCIOS PRÁTICOS GUIADOS INCLUÍDOS NO MANUAL

- Heating efficiency calculation.

- Sugared solution concentration.

- Evaporation velocity determination.

- Study of the evaporation velocity in function of the working conditions.

- Study of the relation between condensed and evaporated product.

- Study of the mass balance of the solute.

- Study of the mass balance of the solvent.

- Energy balance of the evaporation unit.

- Energy balance of the tubular refrigerator.

- Heat transfer global coefficient determination.

- Heat transfer coefficient determination of a tubular refrigerator.

- Study of the mass balance of the solute in one column.

- Fruit juices and vegetable extracts concentration.

- Concentrated milk obtaining.

- Efficiency determination of the steam used in the process.

- Steam generator efficiency determination.

- Investigation of effect of varying process parameters such as: vacuum, flow rate, temperature, recycle rate.

- Sensors calibration.

EXERCÍCIOS MAIS PRÁTICOS A SEREM FEITOS COM A UNIDADE

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EDPAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EDPAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

EQUIPAMENTOS SIMILARES DISPONÍVEIS

Rising Film Evaporator

Double Effect Rising Film Evaporator

Evaporador de Película Descendente, Controlado por Computador (PC)

EQUIPAMENTOS COMPLEMENTARES

Evaporador de Filme Ascendente, Controlado por Computador (PC)

Rising Film Evaporator

Evaporador de Película Descendente, Controlado por Computador (PC)

Double Effect Rising Film Evaporator

Evaporador de Película Fina, Controlado por Computador (PC)

Qualidade

Serviço pós-venda

Preferências de cookies

Preferências de cookies