At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

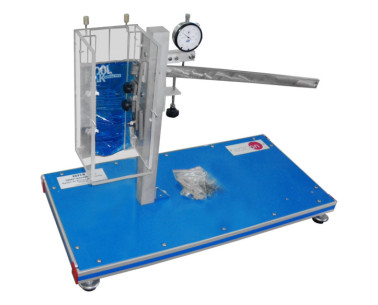

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of Photoelasticity and learn about #elasticity, #fracturemechanics and #materialtesting. #DiscoverEdibon #Engineering.

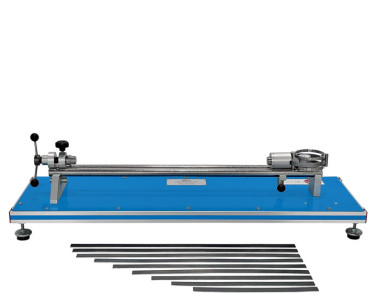

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of 12 days of material resistance and learn about #energy theorems. #DiscoverEdibon #Engineering

Contact us for further information!

Preferências de cookies

Preferências de cookies