At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-ALT Estação de Armazenagem Buffer

SISTEMAS INOVADORES

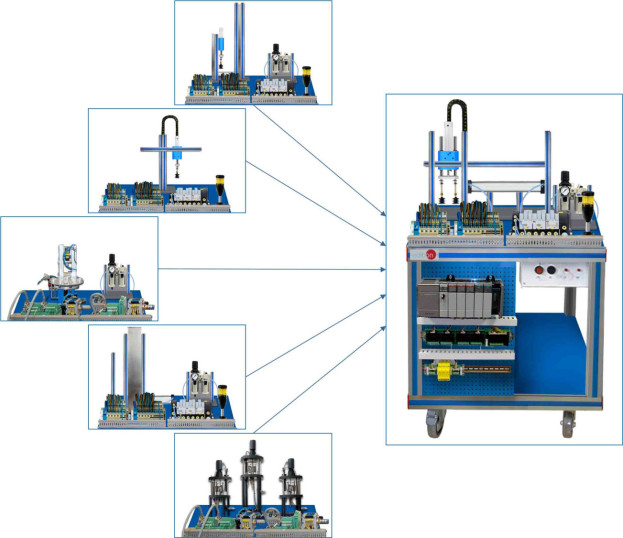

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece.

NOTÍCIAS RELACIONADAS

Descrição Geral

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece. The buffering function is used in many situations in the real industry for security or between different manufacturing stages.

The "AE-PLC-ALT" storage pieces temporarily, till the unit receive a signal that confirm that the next station required another piece.

The "AE-PLC-ALT" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by an AE-PLCB (with HMI devices, analog and digital input/output, etc.) unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, the filters and regulators to assure the appropriate working of the unit.

- The workstation: is composed by real industrial components used by the industrial buffers systems such as reed sensors, a conveyor system with DC motor, IR beam detectors, etc.

The "AE-PLC-ALT" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

EXERCÍCIOS E PRÁTICAS GUIADAS

EXERCÍCIOS PRÁTICOS GUIADOS INCLUÍDOS NO MANUAL

- Introduction to computer-integrated manufacturing (CIM).

- Introduction to pneumatics and electro-pneumatics.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Study an automatic buffer system.

- Change the parameters of the buffering process.

- Optimize the process time.

- Study the faults inserted in the process with the fault generation module.

EQUIPAMENTOS SIMILARES DISPONÍVEIS

6.2.5.8.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE ARMAZENAMENTO

AE-PLC-AL

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three...

6.2.5.8.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE ARMAZENAMENTO

AE-PLC-ALB

Estação de Armazenagem para Garrafas

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup...

6.2.5.8.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE ARMAZENAMENTO

AE-PLC-ALV

Estação de Armazenagem Vertical

The Vertical Storage Workstation, "AE-PLC-ALV", designed by EDIBON, is an automatic storage workstation commanded by a PLC that checks material and dimensions of the incoming pieces to sort in a vertical storage.The "AE-PLC-ALV" uses two electric...

EQUIPAMENTOS COMPLEMENTARES

6.2.5.8.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE ARMAZENAMENTO

AE-PLC-AL

Estação de Armazenagem

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three...

6.2.5.8.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE ARMAZENAMENTO

AE-PLC-ALB

Estação de Armazenagem para Garrafas

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup...

6.2.5.8.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE ARMAZENAMENTO

AE-PLC-ALV

Estação de Armazenagem Vertical

The Vertical Storage Workstation, "AE-PLC-ALV", designed by EDIBON, is an automatic storage workstation commanded by a PLC that checks material and dimensions of the incoming pieces to sort in a vertical storage.The "AE-PLC-ALV" uses two electric...

Qualidade

Serviço pós-venda

Preferências de cookies

Preferências de cookies