EOMC Оборудование для изучения энергии волн, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

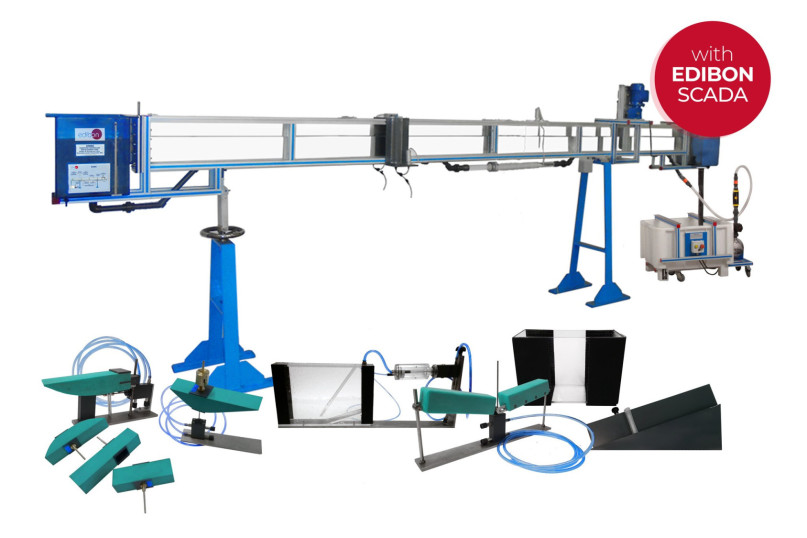

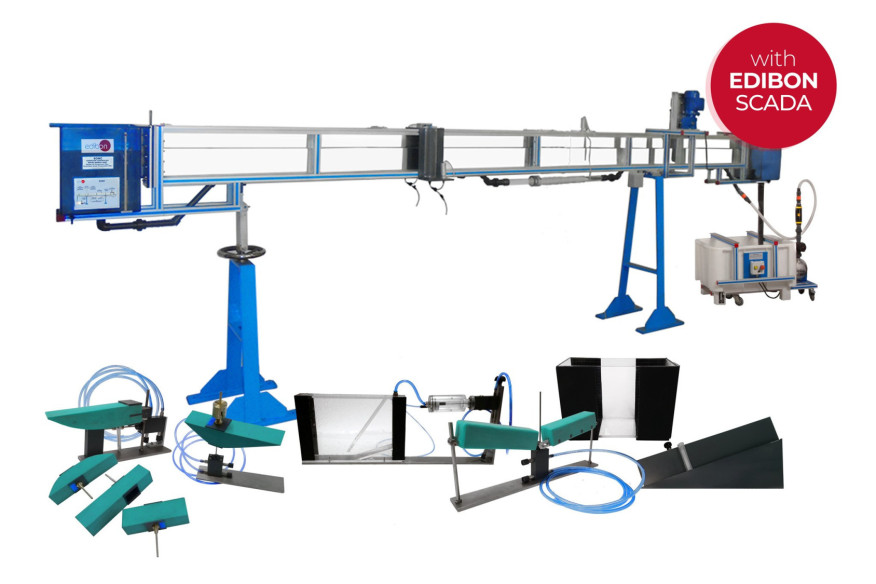

The Computer Controlled Waves Energy Unit, "EOMC", has been designed by EDIBON to study the wave energy and the influence of several variables. The unit consists of a Base Service Unit and Waves Generator "EOMC-UB" and several modules to be used with the "EOMC-UB", which allow to study the conversion from the waves energy into mechanical energy.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Waves Energy Unit, "EOMC", has been designed by EDIBON to study the wave energy and the influence of several variables. The unit consists of a Base Service Unit and Waves Generator "EOMC-UB" and several modules to be used with the "EOMC-UB", which allow to study the conversion from the waves energy into mechanical energy.

The minimum supply consists of two main elements: the Base Service Unit and Waves Generator, "EOMC-UB", and at least one of the required elements described below.

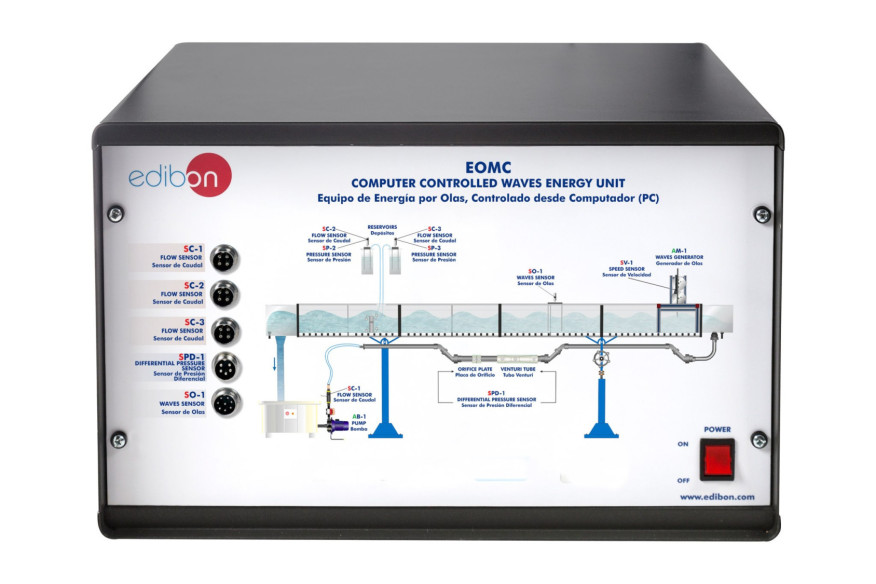

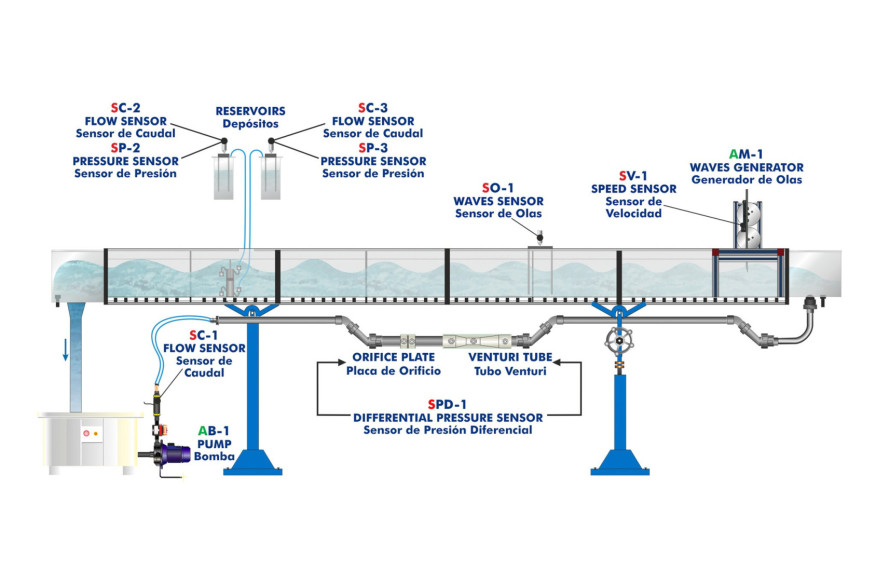

The "EOMC-UB" unit mainly consists of a flow channel and a waves generator:

- CF80/5. Flow Channel (section: 80 x 300 mm), length: 5 m.

- CFGO-K1. Mechanical Wave Generation Elements Kit.

The flow channel consists of a rectangular section with transparent walls through which water is made to circulate. Water is taken from the storage tank by means of a hydraulic pump (computer controlled) and it is driven to the inlet tank through the pipe, where the flow is quietened. Afterwards it circulates through the channel that discharges in the reception tank, returning finally to the storage tank. Thus, the closed circuit is complete. A waves sensor situated on the flow channel allows to measure the height and the frequency of the waves.

To regulate the water flow through the channel, there is a regulation valve at the output of the pump. A flow sensor is situated in the pump outlet to measure the water flow. A differential pressure sensor is used to measure the pressure drop in the orifice plate or in the Venturi tube situated in the water outlet of the pump.

The waves generator produces different types of waves. It is based on a blade that pulls the water, producing the waves. The waves frequency is modified by changing the blade rotating speed. The blade rotating speed can be regulated (computer controlled). The waves size changes according to the displaced amount of water. The amount of water displaced is modified by changing the water level in the tank or adjusting the blade in order to introduce it deeper into the channel. A speed sensor measures the blade rotating speed.

Required elements (at least one) (Not included):

- EOMC-1. Floating Buoy Module.

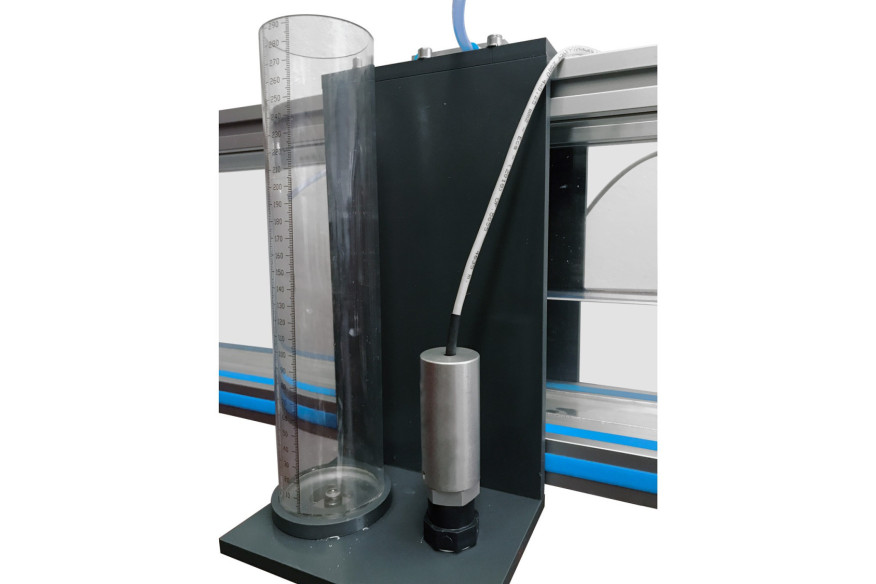

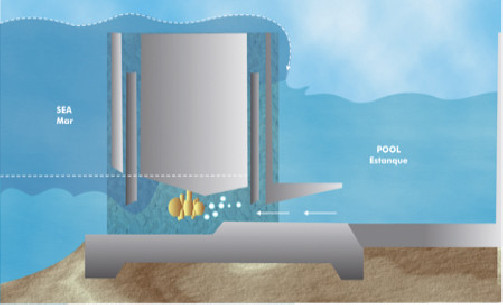

- EOMC-2. Oscillating Water Column Module.

- EOMC-3. Pelamis Module.

- EOMC-4. Tapered Channel Module.

- EOMC-5. Salter's Duck Module.

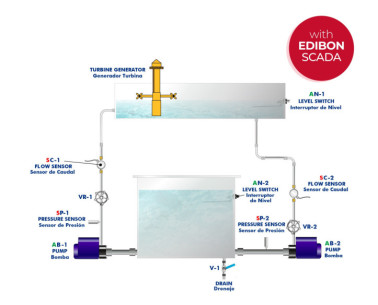

The EOMC-1, EOMC-2, EOMC-3 and EOMC-5 modules include a double acting water pump, able to extract a variable amount of water due to the up thrust of the wave and the down force of gravity. The outlet pipes are routed to two reservoirs mounted on a support. The amount of water collected over a number of wave cycles can be measured. They include two pressure sensors to measure the water height in the reservoirs and two flow sensors to measure the impelled water flow by the Modules.

The Computer Controlled Waves Energy Unit, "EOMC", includes the following elements:

- Base Service Unit and Waves Generator, "EOMC-UB".

- Floating Buoy Module, "EOMC-1".

- Oscillating Water Column Module, "EOMC-2".

- Pelamis Module, "EOMC-3".

- Tapered Channel Module, "EOMC-4".

- Salter’s Duck Module, "EOMC-5".

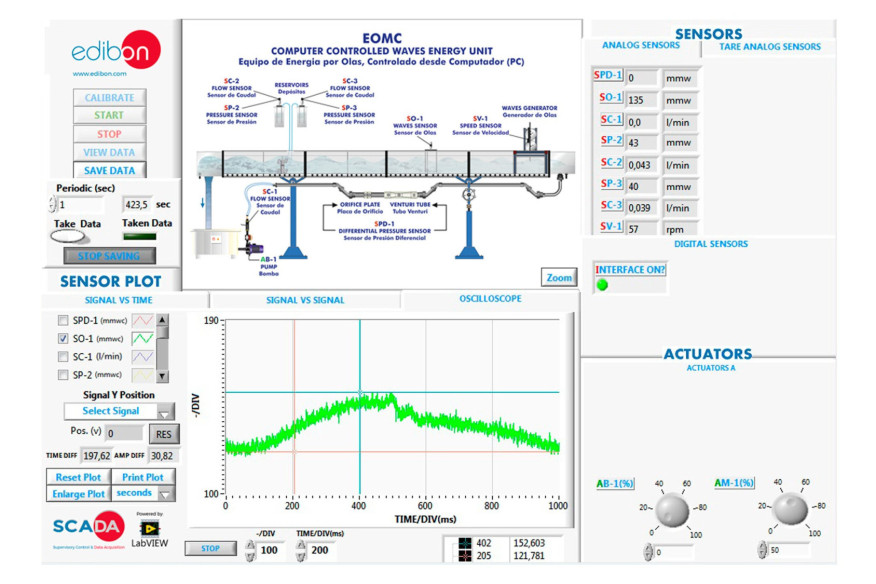

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

Practices to be done with the Base Service Unit and Waves Generator, "EOMC-UB":

- Study of the characteristic parameters of waves.

Practices to be done with the Floating Buoy Module, "EOMC-1":

- Determination of the extracted energy with a floating buoy module.

- Study of the influence of the float shape in the extracted energy with a floating buoy module.

Practices to be done with the Oscillating Water Column Module, "EOMC-2":

- Determination of the extracted energy with an oscillating water column module.

Practices to be done with the Pelamis Module, "EOMC-3":

- Determination of the extracted energy with a Pelamis module.

Practices to be done with the Tapered Channel Module, "EOMC-4":

- Determination of the extracted energy with a Tapered Channel module.

- Study of the effect of slope on the extracted energy with a Tapered Channel module.

- Study of the effect of width contraction on the extracted energy with a Tapered Channel module.

Practices to be done with the Salter’s Duck Module, "EOMC-5":

- Determination of the extracted energy with a Salter’s Duck module.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Measurement of flow using Venturi tube.

- Measurement of flow using orifice plate.

- Study of the different wave’s energy generation systems.

- Study of the operation and performance of the different wave’s energy generation systems.

- Study of the energy available from a wave.

- Study of the Archimedes and buoyancy principles.

- Study of the relationship between wave form and buoyancy.

- Determination of the potential energy in a fluid.

- Study of the float shape in determining energy extraction.

- Study of the compression of air.

- Study of the pneumatic/hydraulic pistons.

- Study of the effect of wave shape on its breaking characteristics.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EOMC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EOMC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Оборудование для Морской Гидрокинетической Энергии (Течения), Управляемая компьютером (ПК)

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie