EMMC Оборудование для изучения приливной энергии, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

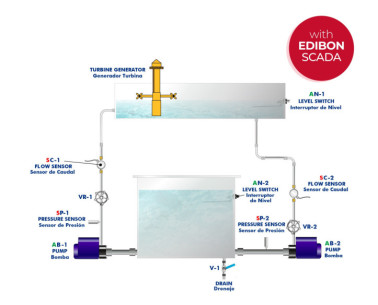

The Computer Controlled Tidal Energy Un"EMMC", is designed for simulating this energy generation system, allowing the study and tests of the operation and performance of a tidal barrage system for energy generation.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

Tidal energy is another way to generate electricity extracting energy from the sea. Twice a day big volumes of water rise and fall with the tides.

A Tidal Barrage make use of the potential energy in the difference in height (or head) between high and low tides.

This system is based on constructing a dam which dams the water entering by a tide into an estuary or pool. Practicing an entry on the dam wall, the water is obliged to enter through it, increasing its speed and, therefore, allowing to use it by turbines for energy generation.

The Computer Controlled Tidal Energy Un"EMMC", is designed for simulating this energy generation system, allowing the study and tests of the operation and performance of a tidal barrage system for energy generation.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Electrical energy generation with different type of tides.

- Measures and controls.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EMMC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EMMC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Оборудование для Морской Гидрокинетической Энергии (Течения), Управляемая компьютером (ПК)

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie