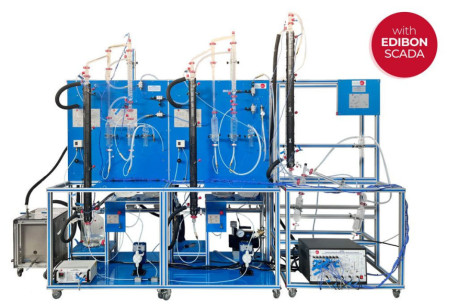

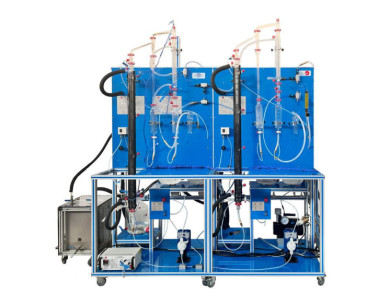

The Computer Controlled and Touch Screen 0.4 l/h Carver-Greenfield Evaporator, "CGE/0.4/CTS", is able to show, for further investigation and study, the removal of dissolved solids from a liquid stream composed of Gamma-Valerolactone (GVL) and furfural.

The unit is composed of a heating chamber with a heating element, a demister to prevent the outflow of thermal oil with the gas phase, two filters for the retention of solids present in the thermal oil, pumps and a cooling system. The unit has two storage tanks.

In the feed tank the mixture is introduced, which is pumped to the evaporation column by means of the pump action. This mixture is brought into contact with the thermal fluid inside the evaporator, which is at high temperature. In this process, the liquid evaporates and the solids are retained in the thermal oil.

The thermal fluid is constantly recirculated to create homogeneity, maintain the right temperature and eliminate as many solids as possible. The solids retained in the thermal oil are separated by filtration through the action of the filters arranged in the unit.

The evaporated stream in the column is condensed in an exchanger, thus obtaining a liquid stream free of solids that is stored in the product tank.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Настройки cookie

Настройки cookie