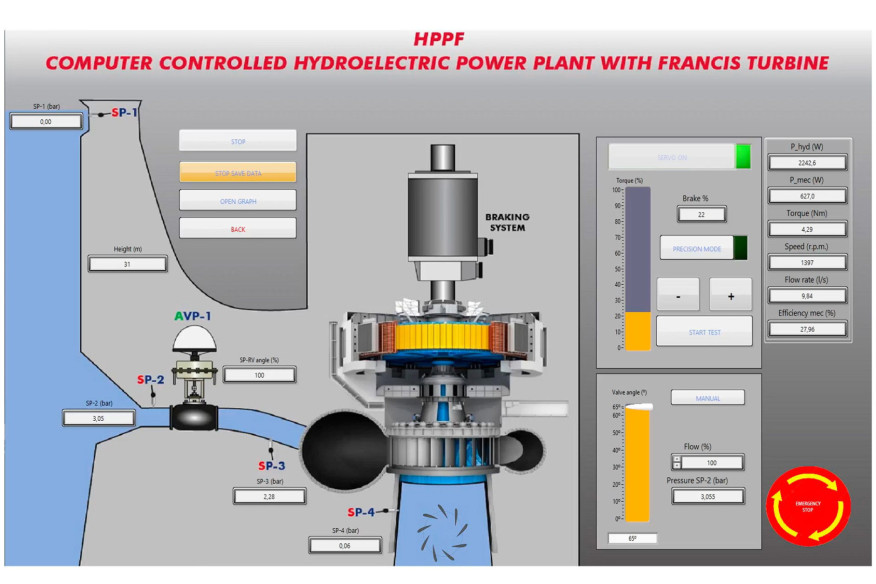

The Computer Controlled Hydroelectric Power Plant with Francis Turbine "HPPF", has been designed by EDIBON with the aim of reproducing, at laboratory scale, the real behavior of an industrial hydroelectric power plant. It allows the user to study, in an integrated way, the process of converting hydraulic energy into electrical energy (requires the recommended accessory HPPF-CR).

Unlike small-scale units, the "HPPF" provides an advanced didactic experience based on real parameters of flow, pressure, and power, achieving an optimal balance between experimental accuracy, robustness, and operational realism.

This approach makes the "HPPF" a high-level teaching tool, intended for university and research training, as well as for technical and professional education, enabling users to analyze the performance, regulation, and control of a complete hydroelectric installation under realistic operating conditions.

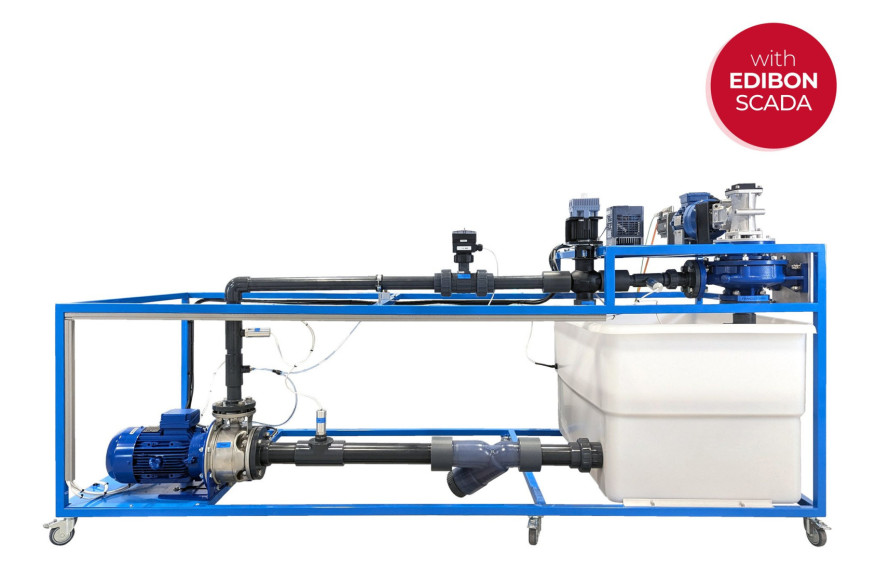

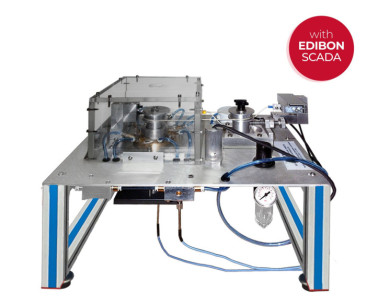

The "HPPF" accurately reproduces the main components and essential principles of a hydroelectric power plant equipped with a Francis turbine. It includes a pressurized hydraulic circuit, a SCADA control and monitoring system, and an electrical generation unit with both analog and digital instrumentation (not included).

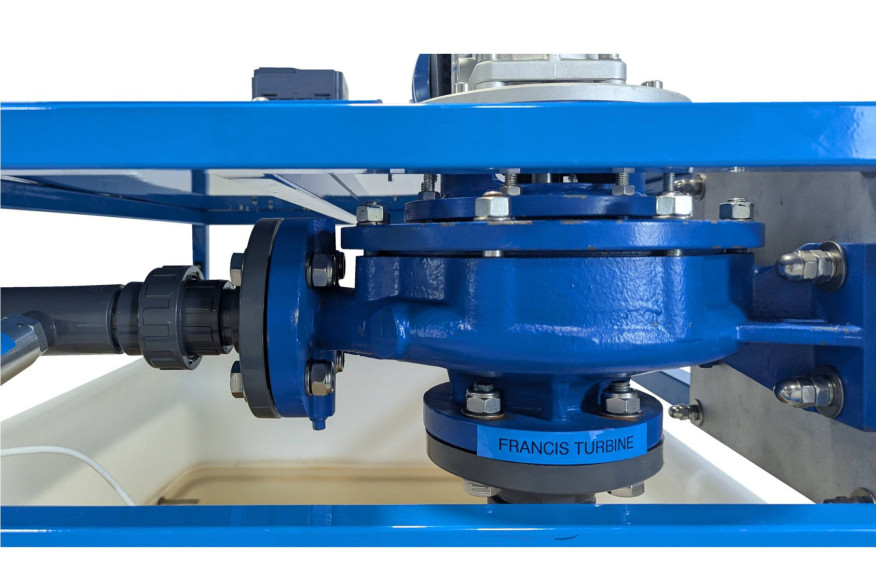

The unit consists of a real Francis turbine (0.75 kW) coupled to a three-phase generator of equal power, a 4 kW centrifugal pump providing the required hydraulic head, and a 400-liter tank acting as the main reservoir.

The hydraulic circuit, made of stainless steel and high-strength PVC, allows pressures of up to 3 bar and flow rates up to 8 L/s, ensuring a stable and controllable flow that enables precise studies of turbine efficiency, regulation, and dynamic behavior.

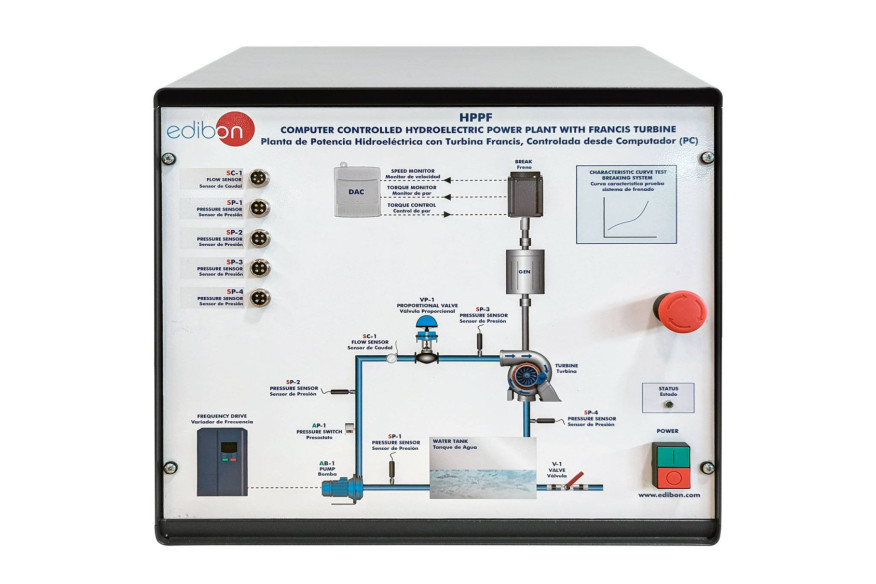

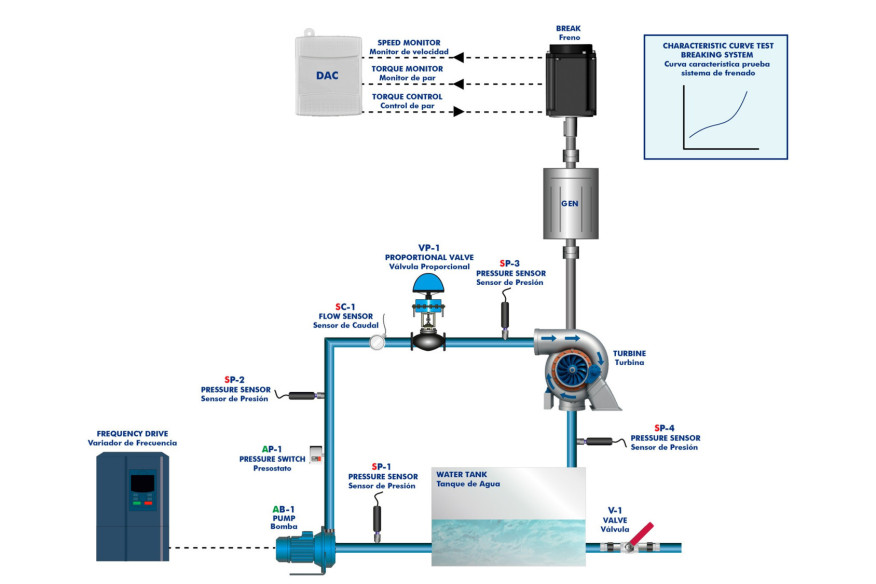

The "HPPF" integrates a complete instrumentation system with flow, pressure, torque, and speed sensors, allowing precise measurement of the main hydraulic and mechanical variables of the process.

For dynamic characterization of the turbine, the plant incorporates a precision servomotor equipped with an incremental encoder, which provides an accurate measurement of the angular speed. Simultaneously, the same servomotor acts as a torque transducer, providing a direct reading of the torque transmitted by the turbine shaft. This configuration enables highly reliable acquisition of power, efficiency, and dynamic performance curves.

For the study of the complete water–turbine–generator–load cycle, the unit can be complemented with the following recommended element.

Additional recommended elements (Not included):

- HPPF-CR: Control and Regulation Unit, which includes automatic control of the turbine and generator, as well as multifunction protection features.

- This unit allows an in-depth study of the electrical phenomena associated with grid synchronization, load analysis, and generator protection.

- The entire set has been designed to provide a realistic and modular experience, which can be configured according to the user’s needs:

- As a pure hydraulic plant, focused on flow and turbine performance analysis (water–turbine cycle).

- As a complete hydroelectric power plant, including electrical generation, control, and synchronization, allowing the study of the full water–turbine–generator–load cycle (requires the HPPF-CR reference).

Thanks to this flexibility, the "HPPF" can be adapted to university laboratories, technical training centers, and research institutions requiring an advanced experimental platform for studying modern hydroelectric systems.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Preferensi cookie

Preferensi cookie