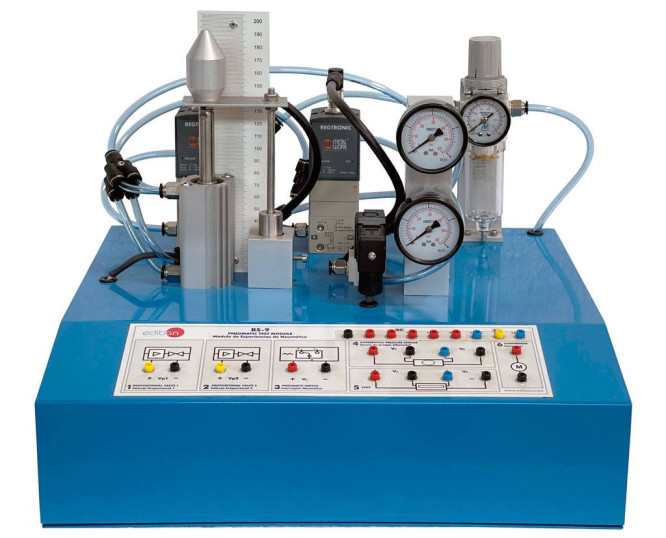

BS9 Modul Pengujian Pneumatik

SISTEM INOVATIF

The Pneumatics Test Module, "BS9", has been designed to teach techniques of control and handling of a pneumatic piston.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Pneumatics Test Module, "BS9", has been designed to teach techniques of control and handling of a pneumatic piston.

All connections of the different BS9 mechanisms will have output through a group of 2 mm. terminals. They are placed in the front panel of the test module with a diagram representing their functions.A double-action pneumatic piston is used to move a platform placed on the upper part of the piston axle. The control of the air inlet to the piston is carried out using two proportional electronic valves.

There is a differential pressure sensor is connected between both pneumatic piston air inlets. This way the pressure difference between both inlets can be obtained any time. At one of the air inlets to the piston there is connected in series a pneumatic switch that works as air output in the circuit.

An compressor, located inside the steel box, must provide the compressed air needed for this unit to operate. A LVDT sensor will indicate the displacement of the pneumatic piston axle. Included elements:

- Two Proportional valves.

- Differential pressure sensor.

- Pneumatic switch (2 positions).

- Linear displacement sensor (LVDT).

- Regulating filter with manometer.

- Manometer indicator of pressure in proportional valve 1.

- Manometer indicator of pressure in proportional valve 2.

- Air compressor (located inside the steel box).

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Proportional valves. To control electronically the vertical displacement of a double effect pneumatic piston using proportional valves.

- Differential pressure sensor. To use a pressure sensor for measuring the pressure difference between both pneumatic piston air inlets.

- Pneumatic switch. To deflect the air flow using a pneumatic switch.

- LVDT Linear Displacement Sensor. To measure pneumatic piston displacement using an excitation and DC output LVDT.

PERALATAN KOMPLEMENTER

Peralatan untuk Studi Pengolahan Sinyal Digital, Dikendalikan dari Komputer (PC)

Peralatan Konverter A/D dan D/A, Dikendalikan dari Komputer (PC)

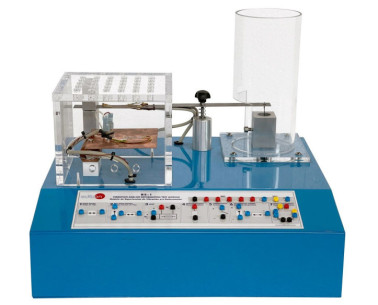

Sistem Modul Pengajaran Sensor

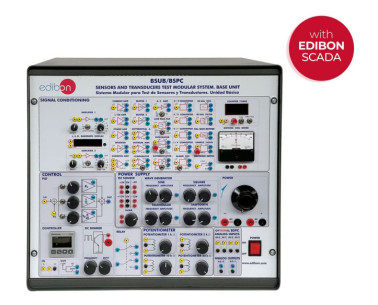

Unit Dasar untuk BS, Dikendalikan dari Komputer (PC)

Unit Dasar untuk BS

Modul Pengujian Getaran dan/atau Deformasi

Modul Pengujian Suhu

Modul Pengujian Tekanan

Modul Pengujian Aliran

Modul Pengujian Oven

Modul Pengujian Level Cairan

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie