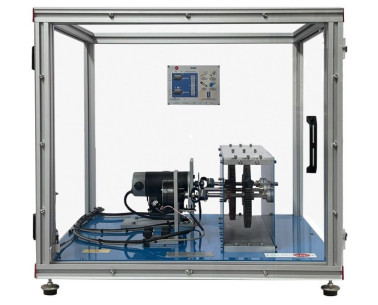

The Dynamic Multistage Gear Train Analysis Unit, "DMGT", has been designed by EDIBON to study the dynamic behavior of a multistage spur gear system, as well as the influence of inertia and motion.

The multistage system consists of an input shaft and 3 drive shafts each with two gears. The possibility of coupling the different shafts independently through the gears themselves makes the "DMGT" unit perfect for analyzing the geometry and dynamics of gears and studying their efficiency in transmitting a given torque.

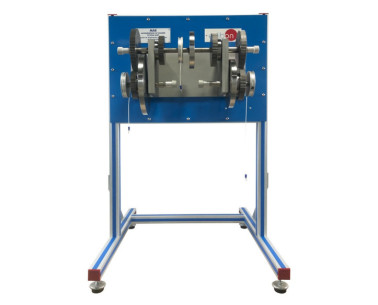

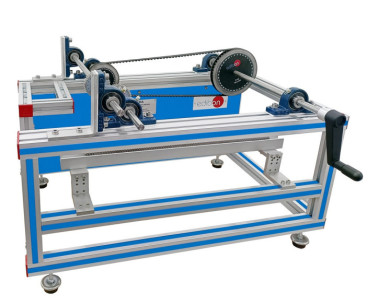

The unit consists of two very recognizable assemblies. On the one hand, the gear system, and on the other hand, the lifting system with crank and weight pulley. To optimize space, the unit is designed in the form of a rectangular box. At the top is the gear system, and below it is a space large enough to allow the weight to be lifted and lowered without any problems.

The lowering of the weight is what allows the transmission of torque, that is, the rotation of the input shaft, and this gives way to the rotation of the rest of the shafts connected to it. As already mentioned, the flexibility of the unit thanks to the possible coupling or decoupling of all the gears is what gives it great efficiency when studying the efficiency in the transmission of power, as well as the study of the forces acting on the different gears.

The unit includes different weights to be able to study the difference produced in the transmission and forces using different input torques, which again provides more versatility in the analysis.

Настройки cookie

Настройки cookie