PHCC Оборудование для Гидроциклона, Управляемая компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

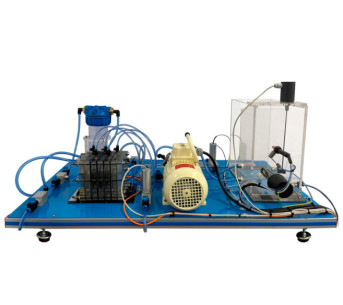

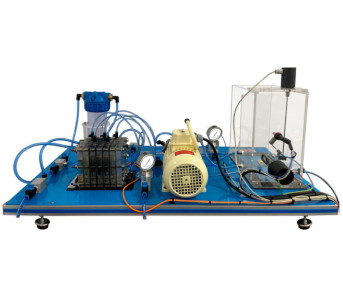

The Computer Controlled Hydrocyclone Unit, "PHCC", has been designed by EDIBON to reproduce on a laboratory scale the operation of industrial hydrocyclones, allowing experimental analysis of the influence of inlet pressure, flow rate, and solids concentration on separation efficiency, as well as observation of the behavior of particles of different sizes under controlled turbulent-flow conditions.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Hydrocyclone Unit, "PHCC", designed by EDIBON, allows the complete study of the solid-liquid separation process by centrifugal action. This laboratory unit accurately reproduces the operating conditions of hydrocyclones used in water treatment, mining, petrochemical, or food industries, providing an educational and research tool for analyzing hydraulic efficiency and particle distribution.

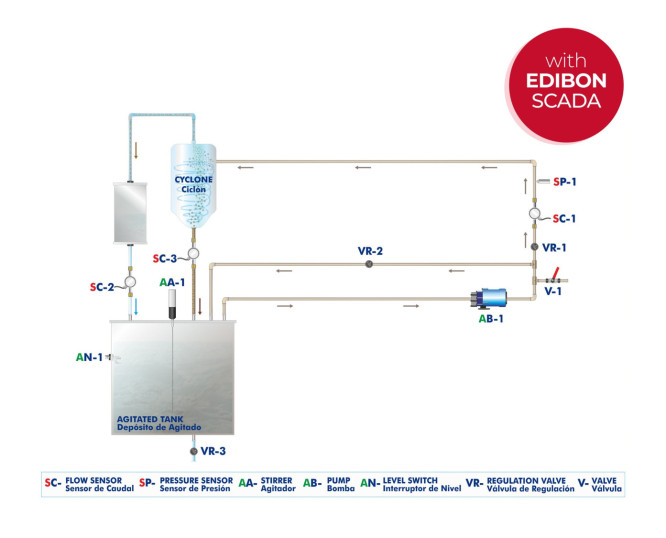

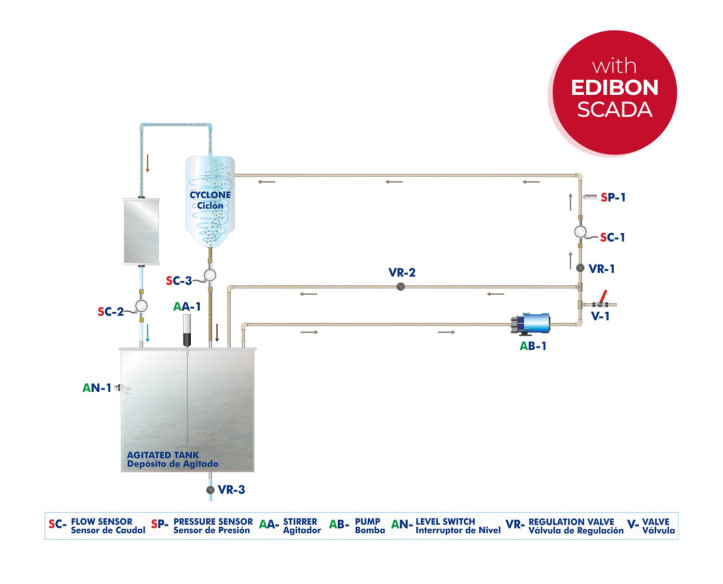

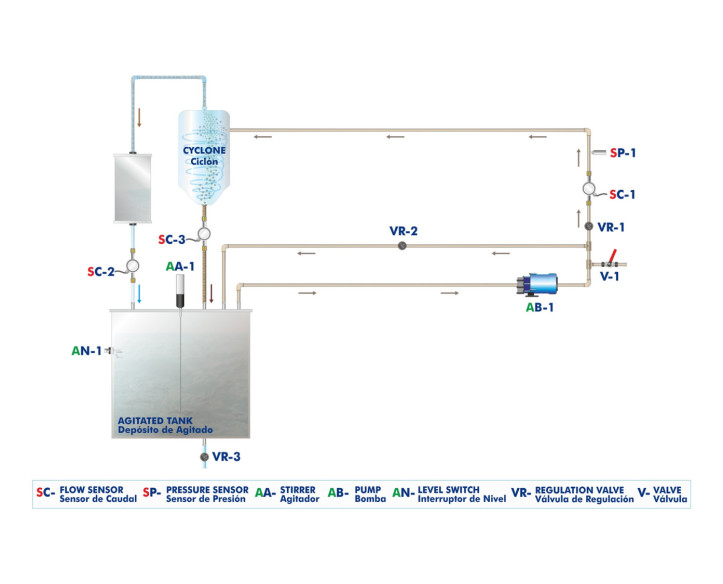

The process begins in a main tank where the suspension of solids in water is prepared. A stirrer, computer-controlled, keeps the mixture homogeneous to prevent the sedimentation of dense particles. A hydraulic pump, also controlled by software, drives the fluid toward the hydrocyclone through the feed circuit. The flow rate can be adjusted by means of a valve and a bypass circuit, allowing precise control of operating conditions.

At the cyclone inlet, pressure and flow sensors record the main process variables, whose values are monitored in real time through the software. This design allows simultaneous control of the pump and stirrer speeds, ensuring stable and reproducible operation.

Inside the hydrocyclone, the centrifugal acceleration generates a high-velocity vortex, in which the coarser particles move toward the internal wall and descend to the lower outlet, where they are discharged. The geometry of the lower part of the cyclone produces a central upward flow that carries the finer particles and clarified liquid toward the upper outlet. A stable air core is formed along the cyclone axis, helping to maintain the structure of the vortex and the separation between the descending and ascending flow zones. In this way, two differentiated streams are obtained: one rich in concentrated solids and the other with clarified liquid, both collected in separate tanks.

The upper part of the cyclone is made of transparent material, allowing direct observation of the flow and vortex formation, which facilitates visual interpretation of the separation process and the analysis of internal flow phenomena.

Both streams can return to the main tank, allowing the process to be repeated in order to study the influence of operating conditions on separation efficiency. The tank includes a level indicator and sampling points at the solid and liquid outlets, facilitating experimental analysis. By studying the collected samples, it is possible to determine the separation efficiency, calculate the cut diameter, and plot the classification curve of the hydrocyclone.

The unit is supplied with test materials quartz sand and diatomaceous earth which make it possible to compare the behavior of particles of different densities and sizes, and to evaluate their influence on process performance.

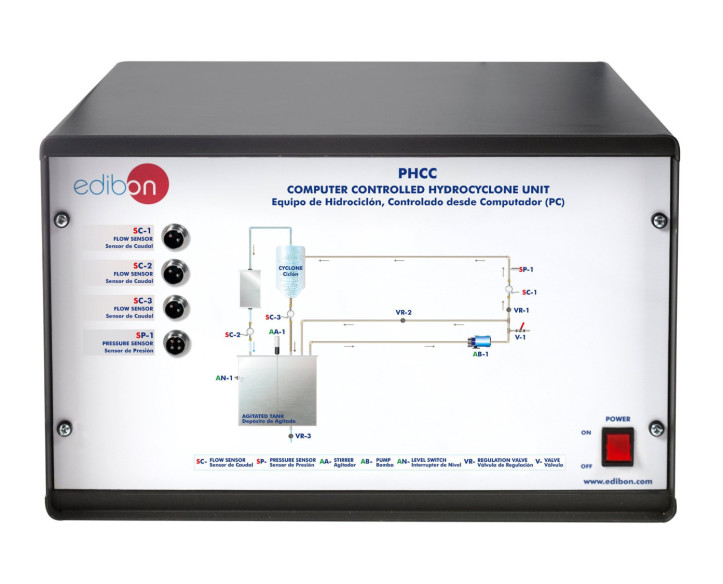

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Study of the operation of a hydrocyclone.

- Measurement of the solids flow rate at key points.

- Measurement of the liquid flow rate at key points.

- Calculation of the hydrocyclone separation quality.

- Pressure drops depending on the initial flow rate.

- Relationship between the pressure drops at the key points and the density of the solid substance.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PHCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PHCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Полуконтинентальный центробежный сепаратор объемом 1000 л, управляемый с ПК и сенсорного экрана

Оборудование для непрерывной и прерывистой фильтрации, управляемое компьютером (ПК)

Оборудование для непрерывной и прерывистой фильтрации

Фильтр-пресс с пластинами и рамами, управляемый с компьютера (ПК)

Оборудование для фильтрации в глубоком слое, управляемое компьютером (ПК)

Оборудование для фильтрации в глубоком слое

Оборудование для изучения осаждения

Отстойный резервуар, управляемый с ПК

Отстойный Резервуар

Дренаж и накопительный бак, управляемый с ПК

Дренаж и накопительный бак

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie