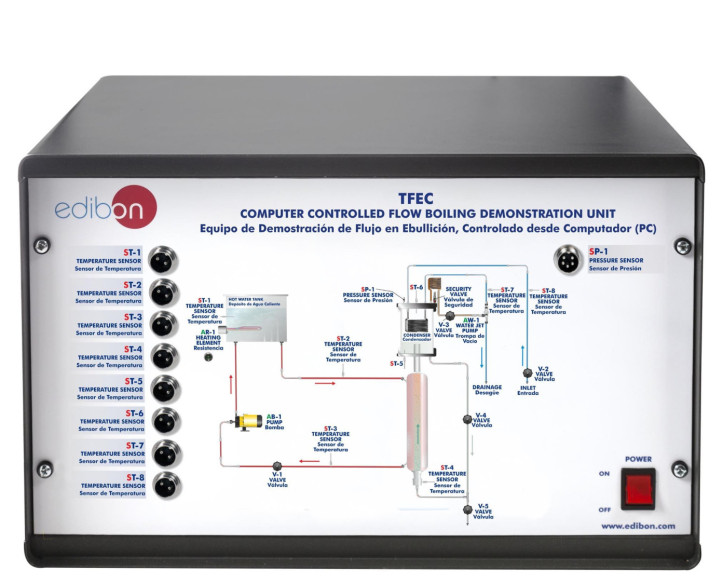

TFEC Оборудование для демонстрации потока при кипении, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

The Computer Controlled Flow Boiling Demonstration Unit, "TFEC", has as main component an experimental tube made of two glass concentric tubes.This unit has been designed for using SES36 refrigerant gas, free of CFC´s, compatible with the Environment.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Flow Boiling Demonstration Unit, "TFEC", has as main component an experimental tube made of two glass concentric tubes. In these tubes two fluids flow crosscurrent: refrigerant, which flows by convection and in an ascendant way through the internal tube, and hot water, which flows in a descendant way through the external tube. This unit has been designed for using SES36 refrigerant gas, free of CFC´s, compatible with the Environment.

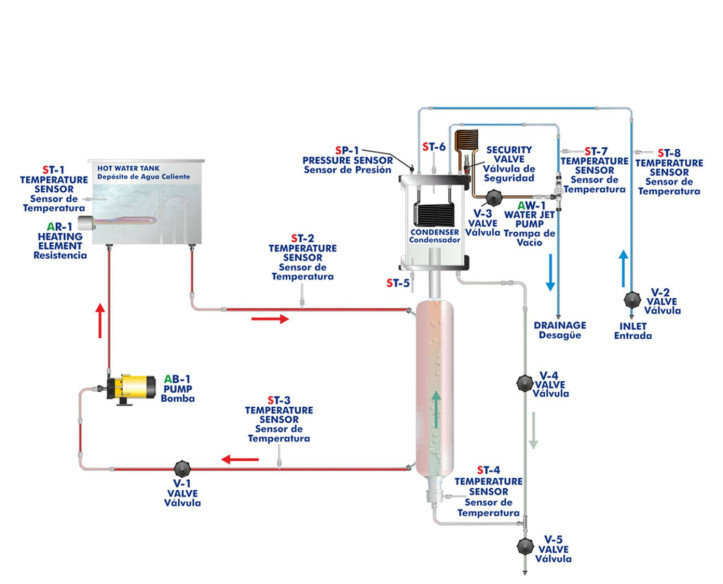

Refrigerant circuit:

The main circuit will be where the different stages of the two-phase flow will be visualised by student.

This circuit is composed of:

- Internal glass concentric tube, where the refrigerant liquid flows.

- Regulation valve for the input flow to the experimental tube.

- Condensing chamber, that is complemented with an absolute pressure sensor which allows to determine the presence of air in the system, a security valve to protect it from possible over pressure. With a temperature sensor the refrigerant temperature into the tank will be visualized. Other temperature sensor shows the temperature of the saturated vapour in the condensing chamber.

Heating circuit:

Basically, this second circuit is composed of:

- External glass concentric tube, through which hot water flows to transfer the hot to the internal tube fluid.

- Thermostatic bath, with a resistance of 600 W. It heats the water in the tank.

- Centrifugal pump for recirculation.

The electric power consumed by the resistance is controlled, from the computer, by PID over the bath temperature.

The heat transfer can be valued because there are two temperature sensors in the refrigerant liquid, in the input and in the output of the concentric tubes.

Finally the condensing chamber has a security valve. It also can be used if we want to carry out the refrigerant charge operation.

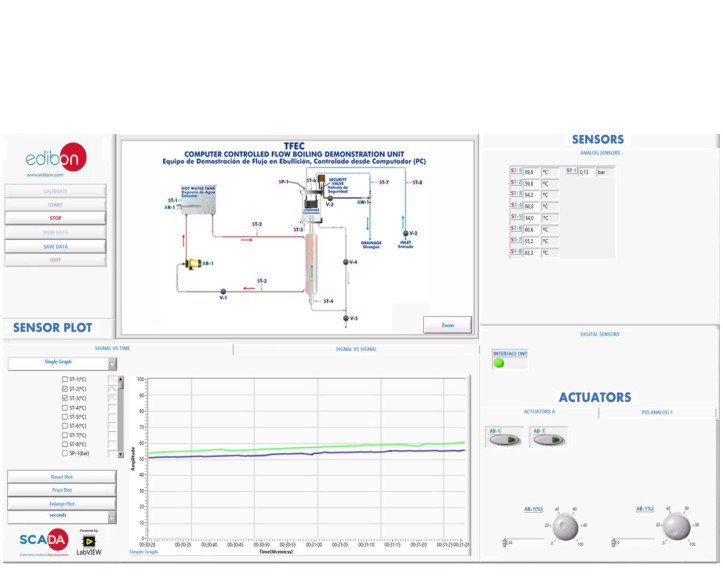

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Visual demonstration of the different types of boiling flow.

- Relationship between pressure and temperature.

- Film condensation.

- Observation of:

- Single-phase liquid flow.

- Sub-cooled boiling.

- Bubbly flow.

- Slug regime.

- Annular flow.

- Film boiling.

- Drop flow (mist).

- Single-phase vapour flow.

- Demonstration of a heating process accompanied by vapour formation within a tube, including:

- Circulation promoted by natural convection.

- Nucleation in sub-cooled and saturated liquid.

- Convective heat transfer to sub-cooled liquid.

- Slugging.

- Droplet entrainment.

- Annular flow.

- Complete dry out to superheated vapour.

- Demonstration of effect of air in condensers.

- Demonstration of two phase flow with increasing vapour content.

- Effect of flow rate on the evaporation process.

- Effect of temperature on the evaporation process.

- Effect of pressure on the evaporation process.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TFEC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TFEC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Оборудование для теплопередачи при кипении, управляемое компьютером (ПК)

Оборудование для теплопередачи при кипении

Оборудование для демонстрации потока при кипении

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie