EEFC Оборудование для испытания на усталость, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

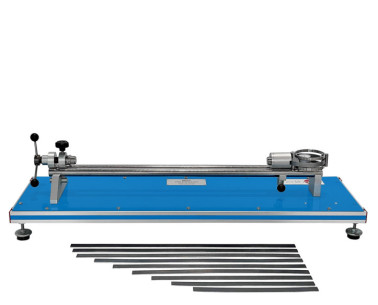

The Computer Controlled Fatigue Testing Unit, "EEFC", designed by EDIBON, allows to study the fatigue strength of the materials. For that purpose, fatigue tests are performed with different materials and notches.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Fatigue Testing Unit, "EEFC", designed by EDIBON, allows to study the fatigue strength of the materials. For that purpose, fatigue tests are performed with different materials and notches.

Optionally, with the additional recommended element Set of Small Specimens, "EEF-SSP", it is possible to study the influence of different rounding radii and surface qualities on fatigue strength.

The Computer Controlled Fatigue Testing Unit, "EEFC", is compatible with all available specimen sizes.

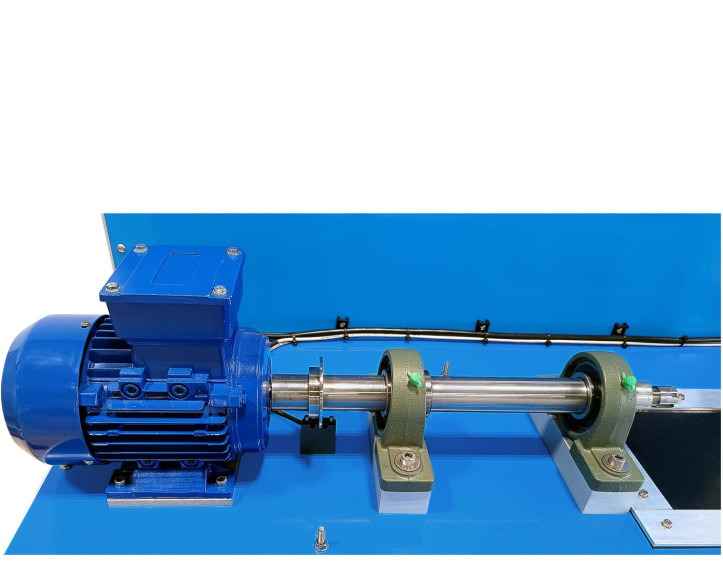

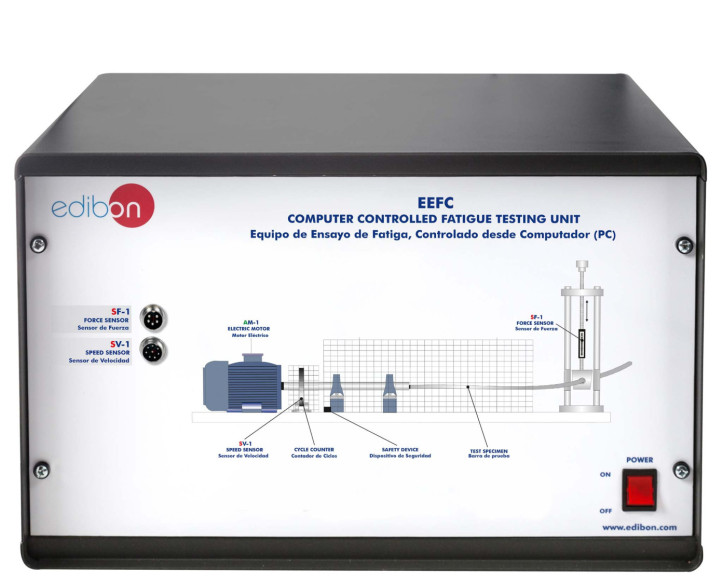

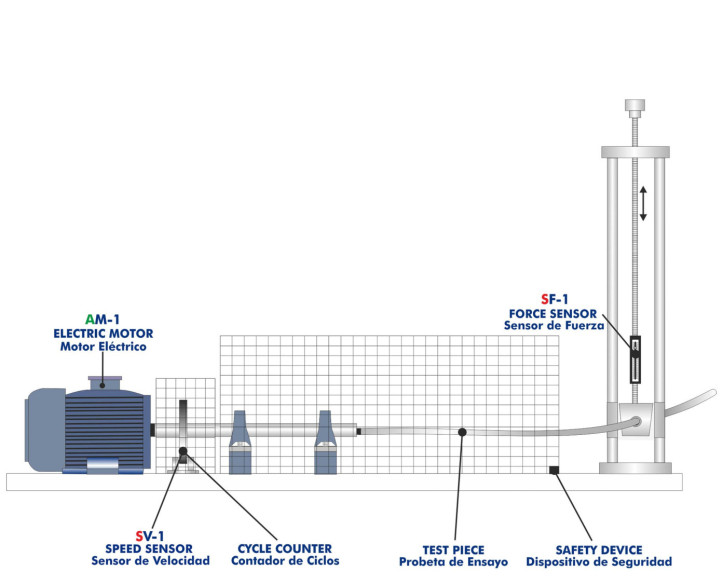

An electric motor is fixed to the lower panel of the unit. One end of the test piece is joined to the motor shaft by a coupling. A disc which will count the number of rotations of the motor thanks to a device and a speed sensor for the motor are also coupled to the shaft. The speed can be controlled and changed through the computer.

On the right side of the panel, it is placed the system with which the test piece is loaded. This system, with a load cell (force sensor), is joined to a threaded spindle by its upper end, while on its lower side it is joined to an articulated guided system to which the right end of the test piece is held. When turning the threaded spindle clockwise, an upward vertical force is transmitted to the test piece. The applied force can be measured with the load cell (force sensor).

In order to guarantee the force verticality, the system has two guides to avoid horizontal displacements during the transmission of stress.

Likewise, in order to assure the constant application of the load, besides of allowing the test piece rotation on its axial symmetry axis, the system also allows the alignment of the coupling with the test piece, due to the bending deformation it suffers.

Both the area where the test piece is located and the motor axis output are covered with a protection cage, without it the unit does not work, since it is provided with a safety system to avoid accidents.

Besides, it includes a control switch that detects when the test piece is broken and switches off the motor right away.

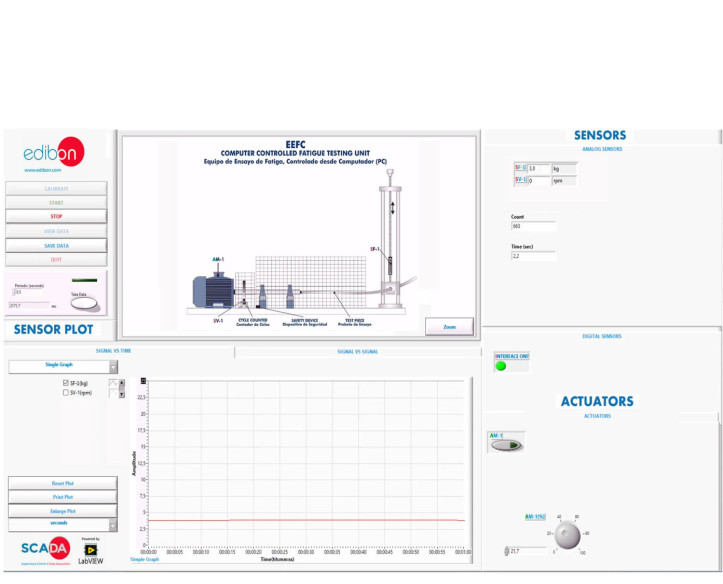

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Determination of the basic principles of fatigue strength testing.

- Influence of the material on fatigue strength.

- Influence of the notch effect on fatigue strength.

- Influence of the length of the notch on fatigue strength.

- Representation of Wöhler fatigue strength S-N curves.

- Physical analysis of the regions formed in the rupture of pieces in the fatigue test.

- Influence of different rounding radii and qualities of surface on fatigue strength (requires the additional recommended element "EEF-SSP").

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EEFC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EEFC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Универсальное оборудование для испытания материалов

Оборудование для испытания твердости "Бринелль"

Оборудование для испытания твердости "Бринелль", "Виккерс" и "Роквелл"

Оборудование для испытания ползучести

Оборудование для испытания на усталость

Оборудование для Испытаний на Ударную Вязкость по Шарпи и Изоду

Оборудование для Испытания на Удар по Методам Шарпи и Изода, 300Нм

Универсальное оборудование для испытания на изгиб

Оборудование для изучения изгиба стержней

Оборудование для изучения модов панелирования Эйлера

Оборудование для изучения кручения и изгиба

Оборудование для изучения кручения

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie