At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

Today, we can announce the setting up of a complete installation, including the Linear Heat Conduction Module TXC/CL, TXC/CC, TTEC, MINI-EEE, EEU/20KN or EBVR, among others, at the University of Sebha, in Libya. We are confident that this new equipment will allow students to test empirically the...

We are very pleased to continue with our expansion and installation of equipment in different universities. This time, we are happy to equip the Al-Balqa' Applied University - Financial & Administrative Sciences . The students will be able to continue learning with the EBVR, that allows...

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of Photoelasticity and learn about #elasticity, #fracturemechanics and #materialtesting. #DiscoverEdibon #Engineering.

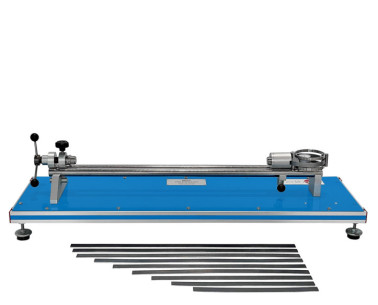

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of 12 days of material resistance and learn about #energy theorems. #DiscoverEdibon #Engineering

Contact us for further information!

Настройки cookie

Настройки cookie