CA00 Пилотные заводы для мясной продукции, управляемые с помощью компьютера (ПК) и сенсорного экрана

ИННОВАЦИОННЫЕ СИСТЕМЫ

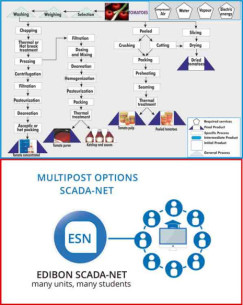

The Computer Controlled and Touch Screen Pilot Plants for the Production of Meat, "CA00", is a pilot plant to investigate the main processes of the meat industry, obtaining cured meat products, cooked meat products, sausages and pre-cooked products as final products.

ЛАБОРАТОРИИ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled and Touch Screen Pilot Plants for the Production of Meat, "CA00", is a pilot plant to investigate the main processes of the meat industry, obtaining cured meat products, cooked meat products, sausages and pre-cooked products as final products.

The "CA00" pilot plant is subdivided in several pilot plants with the purpose of covering and giving a detailed solution to all the industries involved in the treatment of meat. In each of the different pilot plants aimed at the treatment of meat products, it is possible to add a weighing platform and a scale to determine the weight of the product to be treated (a necessary step for any subsequent process). In addition, there is a meat reception cabinet in which the raw pieces are kept at the right temperature for their preservation before being treated.

Other accessories are also available to increase the possibilities of each of the pilot plants involved in the different processes.

- CA00/CUPS. Pilot Plant for the Production of Cured Pieces and Sausages. With this pilot plant, designed by EDIBON, we are able to obtain cured products from untreated meat following the following process:

First, the meat that has been weighed and cleaned of unwanted parts is fed into a mincer to obtain minced meat and then into a mixer in which the meat is mixed with the different additives (salt, spices, preservatives, etc.)

The next step is the stuffing of the meat already kneaded, for which a stuffing machine is used to facilitate the introduction of the product into the casing, whether natural or artificial.

The casing is then tied and fastened to seal the sausage, thus producing a fresh product.

Finally, by using a drying cabin in which the humidity and temperature conditions are controlled, we obtain a product with the desired properties.

This pilot plant also allows the production of whole cured pieces of meat undergoing a previous salting or marinating process. For this purpose, tanks suitable for the treatment of salted or marinated meat are supplied.

It is also possible to produce cured pork loin. The last step consists of storing the cured or salted pieces for a long enough period of time under the conditions indicated for each product.

For this pilot plant, the pieces produced can be vacuum-packed to guarantee greater durability and hygiene.

- CA00/COPS. Pilot Plant for the Production of Cooked Pieces and Sausages. With this pilot plant, designed by EDIBON, we are able to obtain cooked products from untreated meat, following the following process:

To prepare this type of product, the first step is to inject brine into the pieces of meat to eliminate the remains of blood and add flavor and juiciness to the final product.

Subsequently, we will use a maceration pump with a vacuum system to massage and achieve correct distribution of the brine throughout the piece.

From here and depending on the purpose, we follow two different ways:

- 1) If whole cooked pieces are going to be processed, the next step is to place the piece in an Electric Cooking Kettle and cook it.

- 2) On the other hand, if the final product is a cooked sausage, the massaged piece must be taken to a mincer, in which the blades will grind the meat until a very fine mass is obtained, at which time the additives are also added. Once the mass is ready, a vacuum filler must be used, since there can be no air inside the sausage during cooking. The sausage is then pressed and cooked in an Electric Cooking Kettle in water or steamed in a Forced Air and Steam Oven.

For this pilot plant, the pieces produced can be vacuum-packed to ensure greater durability and hygiene.

- CA00/PM. Pilot Plant for the Production of Precooked Meat Products. With this pilot plant, designed by EDIBON, it is possible to study and research in the elaboration of precooked food from meat products, mainly meatballs and croquettes. Meat processing is carried out in the following way:

Previously, the meat is prepared by kneading it in hot dough and mincing it.

The processed meat is then placed in a blast chiller to lower its temperature and avoid the proliferation of bacteria.

If we want to make hamburgers, the meat goes through a hydraulic press. If we want to make meatballs, the meat will go through a breading machine.

Once the meat has been treated, it goes through a fryer to cook it.

In addition, there are two types of sealers, a conventional thermosealing machine and another that introduces an inert gas inside the tray to ensure better preservation.

Finally, it is possible to label the containers using a scale with a labeler to indicate the weight of the product and its ingredients if the final product is to be marketed.

This computer controlled unit is supplied with the EDIBON Control System (SCADA), and includes: The unit itself + Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Study of the mincing process of raw meat.

- Study of the kneading of minced meat and the additives used.

- Study of the sausage making process in a conventional sausage maker.

- Study of the influence of the speed of operation on the sausage making process.

- Study of the sausage tying process.

- Study the stapling process using a manual stapler.

- Study of the stapling process of sausages using a pneumatic stapler.

- Study of the vacuum packing process.

- Injection of brine into meat pieces.

- Study of the massage process of meat pieces injected with brine.

- Study of the influence of brine injection on the final product.

- Study of the process and speed of mincing in a meat cutter.

- Study the sausage process using a vacuum filler.

- Study the differences between a traditional sausage and a vacuum sausage.

- Study the process of molding cooked pieces.

- Study of the cooking process of sausages and meat pieces. Influence of the time and temperature in cooking process.

- Cooking of steamed meat products.

- Study of the differences between cooking in kettle and steaming.

- Study of the salting process of meat pieces.

- Study of the marinating process of meat pieces.

- Study of the maturing process of meat products.

- Influence of the humidity and temperature in the process of maturation.

- Preparation of meatballs and croquettes.

- Study of the preparation of cooked food from meat products.

- Study of the operation of a temperature chiller.

- Study of the functioning of a thermosealing machine.

- Study the operation of a thermosealing machine with inert gas injection.

- Influence of the frying time on cooked food.

- Weighing and labeling of processed foods.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Sensors calibration.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

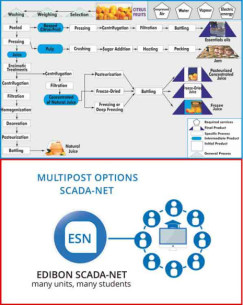

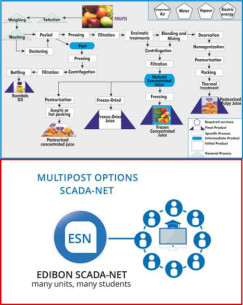

Пилотные установки для фруктов, управляемые компьютером (ПК) и сенсорный экран

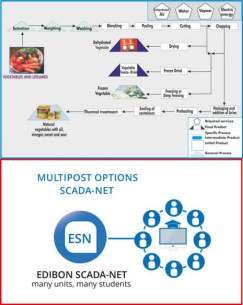

Пилотный завод для овощей и бобовых, управляемый с компьютера (ПК) и сенсорным экраном

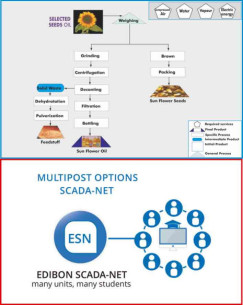

Пилотный завод для производства масла из семян, управляемый с помощью компьютера (ПК) и сенсорного экрана

Пилотный завод для производства масел, управляемый с помощью компьютера (ПК) и сенсорного экрана

Пилотный завод для томатов, управляемый с компьютера (ПК) и сенсорным экраном

Пилотный завод для обработки винограда, управляемый с компьютера (ПК) и сенсорным экраном

Пилотные заводы для производства зерновых культур, управляемые с помощью компьютера (ПК) и сенсорного экрана

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Оборудование для экстракции растворителя и десорбции, управляемое компьютером (ПК)

Оборудование для гидрирования, управляемое с компьютером (ПК)

Оборудование для дезодорации, управляемое компьютером (ПК)

Учебная холодильная камера, управляемая с ПК

Обучающее устройство для розлива воды в пластиковую тару, управляемое с ПК

Учебное оборудование для упаковки твердых веществ, управляемое компьютером (ПК)

Фильтр-пресс с пластинами и рамами, управляемый с компьютера (ПК)

Установка для производства масла в непрерывном цикле, управляемая с компьютера (ПК)

Пилотный завод по цитрусовым, управляемый с компьютера (ПК) и сенсорным экраном

Пилотные установки для фруктов, управляемые компьютером (ПК) и сенсорный экран

Пилотный завод для овощей и бобовых, управляемый с компьютера (ПК) и сенсорным экраном

Пилотный завод для производства масла из семян, управляемый с помощью компьютера (ПК) и сенсорного экрана

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie