UCP-P Peralatan Pengendalian Proses untuk Studi Tekanan (Udara), Dikendalikan dari Komputer (PC)

SISTEM INOVATIF

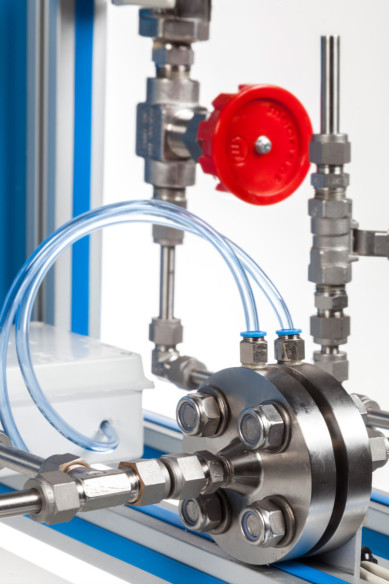

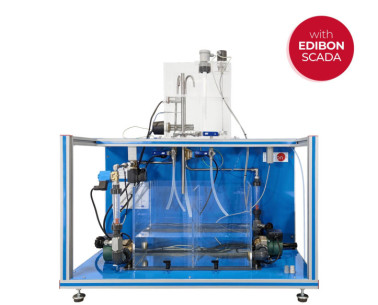

The Computer Controlled Process Control Unit for the Study of Pressure (Air), "UCP-P", consists of a compressed air duct whose flow is controlled by a pneumatic valve (the compressed air or gas source is not included).

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Computer Controlled Process Control Unit for the Study of Pressure (Air), "UCP-P", consists of a compressed air duct whose flow is controlled by a pneumatic valve (the compressed air or gas source is not included).

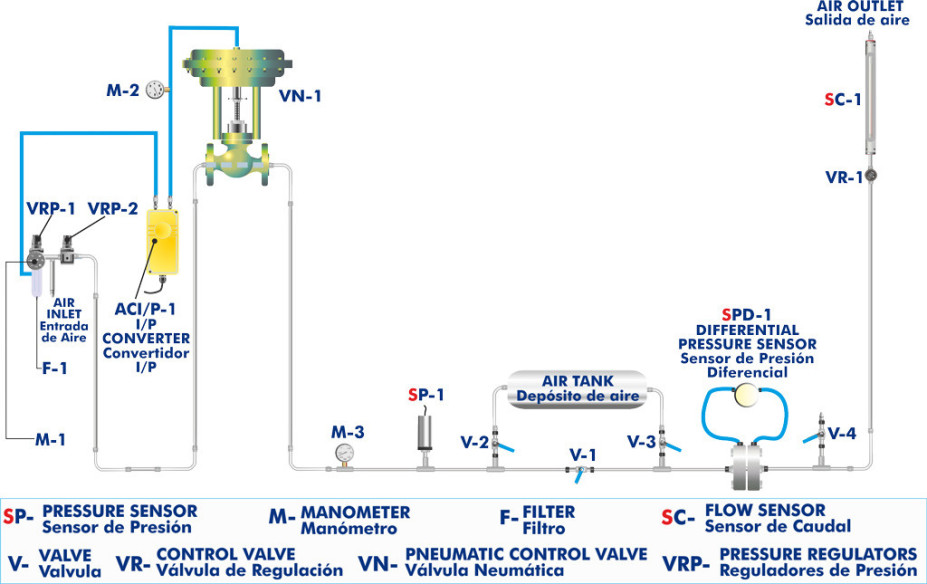

The air is supplied through the air inlet and it can be diverted with two pressure regulators toward the circuit which controls the valve or the circuit where the pressure and flow will be controlled.

The valve control circuit is composed by an I/P converter, which transforms the electrical signal send by the computer in a pneumatic signal, and a manometer placed between the I/P converter and the valve.

The main circuit, whereby the flow and pressure will be controlled, is composed by an absolute pressure sensor and a manometer to control the pressure, an orifice plate with a differential pressure sensor and a flowmeter to control the flow and four manual valves to introduce disturbances in the system and to change its configuration adding an air tank to the duct for the study of the volume effect in the control system.

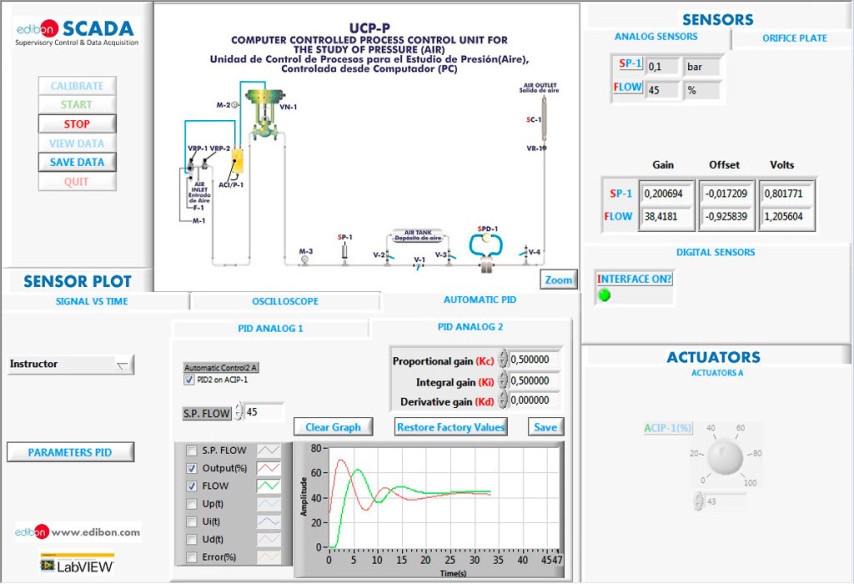

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Analysis of non-linear behaviors in control systems: hysteresis, death zone, saturation, etc.

- Study of the effect caused by the volume in flow and pressure control systems.

- Characterization of the pressure and flow behavior of an air duct.

- Study of the structure and operation of a PID controller.

- Flow and pressure control using different configurations of a PID controller (P, PI, PID).

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the UCP-P unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the UCP-P unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

PERALATAN KOMPLEMENTER

Kontrol Proses (Katup Elektronik), Dikendalikan dari Komputer (PC)

Kontrol Proses (Katup Pneumatik), Dikendalikan dari Komputer (PC)

Kontrol Proses (Inverter Kecepatan), Dikendalikan dari Komputer (PC)

Kontrol Proses (Katup Elektrik + Pneumatik dan Inverter), Dikendalikan dari Komputer (PC)

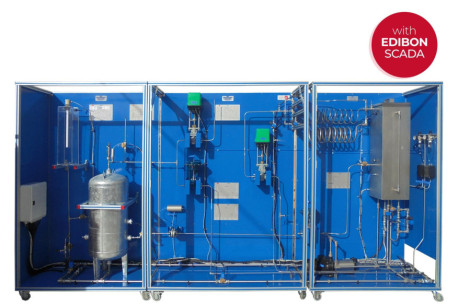

Pabrik Kontrol Proses Industri, Dikendalikan dari Komputer (PC)

Pabrik Kontrol Proses Industri (hanya Aliran), Dikendalikan dari Komputer (PC)

Pabrik Kontrol Proses Industri (hanya Suhu), Dikendalikan dari Komputer (PC)

Pabrik Kontrol Proses Industri (hanya Tingkat), Dikendalikan dari Komputer (PC)

Pabrik Kontrol Proses Industri (hanya Tekanan), Dikendalikan dari Komputer (PC)

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie