TFUC Peralatan Filtrasi Kontinu dan Diskontinu, Dikendalikan dari Komputer (PC)

SISTEM INOVATIF

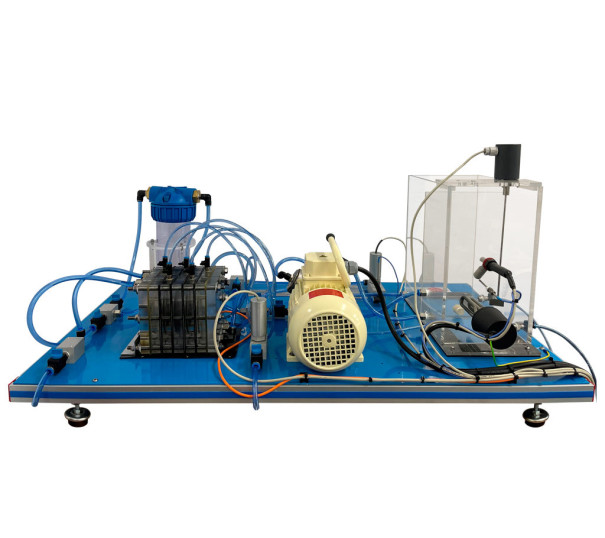

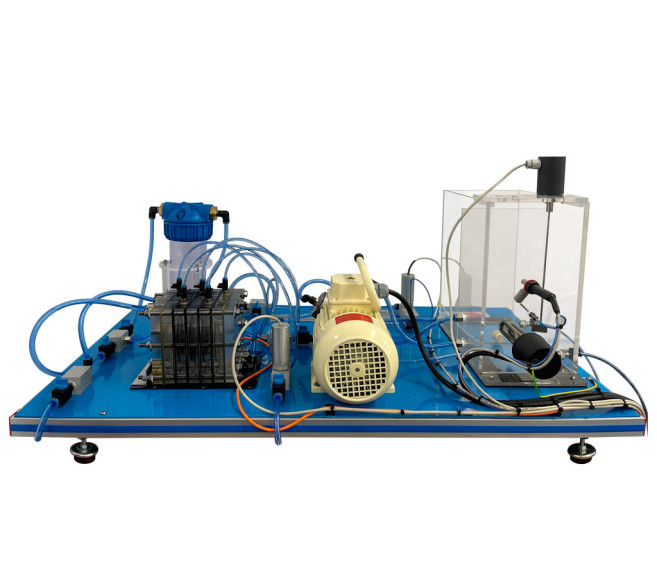

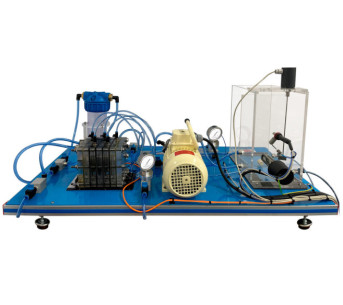

The Computer Controlled Continuous and Batch Filtration Unit, "TFUC", has been designed to understand the principles of continuous and batch filtration at constant pressure and constant flow operation.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

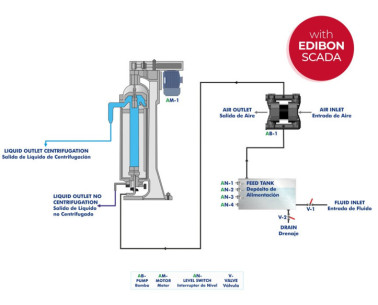

This filtration unit has been designed to study the filtration process with two different types of filters. On one hand, there is a vertical plate filter consisting of nylon plates with a diameter of 5 microns, used to filter a known concentration CaCO3 suspension. On the other hand, there is a cartridge filter, more suitable for continuous filtration of larger size materials. It will be used to filter and "clean" a water sample with small pieces of paper.

To carry out the experiments, the mixture will be taken from a tank by a computer controlled centrifugal pump and send to one of the filters depending on the position of the valves. A motor driven stirrer will make the sample inside the tank more homogeneous.

Along its way, the mixture goes through two pressure sensors and a flow sensor, which will help us to determine the flow through the circuit. The initial temperature of the sample can be controlled by a heating element and a temperature sensor (PID Control), which will provide the temperature value at any time.

There are two operation modes with the unit: the filtered product can be sent to the initial tank to be filtered again or to a "product tank" to be analyzed after passing through the filters only once. Besides, the unit can work at constant flow and at constant temperature.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Understanding the principles of continuous and batch filtration using both constant pressure and constant flow operating modes (vertical plates and cartridge filters).

- Study of the plates filter at a constant pressure.

- Study of the plates filter at a constant flow.

- Study of the cartridge filter at constant pressure.

- Study of the cartridge filter at constant flow.

- Demonstrating filtration through membrane technology.

- Precoat and body aid filtration.

- Optimisation of filtration performance using body aid.

- Determination of medium and cake resistances.

- Effect of body aid on medium and cake resistances.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

Additional practical possibilities to be done by the end customer:

- Mass balancing.

- Demonstration of Darcy’s Law.

- Filter cake washing and dewatering.

- Study of commercial aspects of filtration and optimisation of filtration operations.

Oher possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TFUC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TFUC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

PERALATAN SIMILAR TERSEDIA

PERALATAN KOMPLEMENTER

Pemisah Sentrifugal Semi-Kontinu 60 L, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pemisah Sentrifugal Semi-Kontinu 1000 L, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Peralatan Filtrasi Kontinu dan Diskontinu

Filter Press Pelat dan Bingkai, Dikendalikan dari Komputer (PC)

Peralatan Filtrasi Lapisan Dalam, Dikendalikan dari Komputer (PC)

Peralatan Filtrasi Lapisan Dalam

Peralatan Studi Sedimentasi

Tangki Sedimentasi, Dikendalikan dari Komputer (PC)

Tangki Sedimentasi

Tangki Filtrasi dan Drainase, Dikendalikan dari Komputer (PC)

Tangki Filtrasi dan Drainase

Peralatan Osmosis Terbalik/Ultrafiltrasi, Dikendalikan dari Komputer (PC)

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie