In an increasingly globalized world, where eating habits evolve at the same pace as technology, Food Technology has become an essential pillar of our...

In an increasingly globalized world, where eating habits evolve at the same pace as technology, Food Technology has become an essential pillar of our...

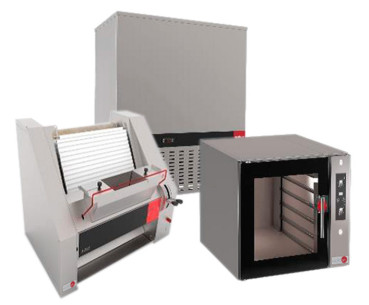

Pilot plants are small-scale processing plants designed to simulate industrial or research processes before large-scale implementation. They are essential for testing technologies, optimizing processes, and validating models before investing in mass production. These plants allow researchers and...

In a world where energy demand continues to rise and non-renewable resources are rapidly depleting, the need for sustainable, environmentally friendly solutions has never been more urgent. The circular economy and the use of organic biomass to produce biofuels are emerging as key answers to...

Direct Air Capture (DAC) adalah teknologi inovatif yang menghilangkan CO₂ langsung dari udara menggunakan reaksi kimia dengan pelarut cair atau penyerap padat. Meskipun menghadapi tantangan seperti biaya tinggi dan konsumsi energi, DAC menawarkan solusi potensial untuk mengurangi konsentrasi CO₂...

Discover how our innovative and sustainable pilot plants can transform food production. Ensure quality, efficiency, and sustainability at every stage of the production process.

We are back at the Teagasc In Ireland! We have travelled to the centre to expand the Pilot Plant for Cereal Malting. We made this pilot plant specifically to meet the needs of the centre.

At Edibon we had the honor of making a very important installation in the Department of Agriculture and Food development Authority (TEAGASC) of Carlow, Leinster (Ireland) For them, we have custom designed and manufactured this Pilot Plant for Cereal Malting. We are sure that it will help students...

Preferensi cookie

Preferensi cookie