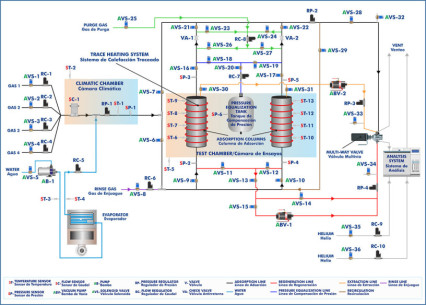

The Double Column Gas Absorption Unit, "CAG/CD", designed by EDIBON, allows a complete study of gas absorption and desorption processes in packed columns, accurately reproducing the operating conditions used in the chemical and environmental industries. The unit enables the absorption of gases such as carbon dioxide (CO₂) from a gas mixture with air, using an aqueous solution that flows downward in countercurrent through the absorption column.

The unit consists of two packed glass columns, one intended for absorption and the other for desorption. Both are filled with glass Raschig rings as packing material, providing a large contact surface between the gas and liquid phases. Each column includes glass ends for gas and liquid inlet and outlet, as well as sampling points that allow observation and analysis of the process. The sampling points in the gas and liquid lines make it possible to perform comparative analyses at different positions in the system, facilitating graphical representation of the gas-liquid equilibrium and the experimental determination of absorption efficiency.

The liquid circuit (water) is composed of a storage tank, a centrifugal pump with adjustable flow rate, a flowmeter, a glass diffuser shower, and control valves that allow regulation and measurement of the flow circulating through the unit. The liquid enters the column from the top and, after the absorption process, can be recirculated or directed to the desorption column, where, in countercurrent with clean air, the dissolved gas is released, continuously regenerating the solvent. The desorption process can be studied by varying the solvent temperature through a controlled heating system, allowing analysis of temperature influence on the efficiency of gas regeneration.

The gas circuit (air and CO₂) includes a compressor (blower) that supplies air to the system and a connection for the addition of another gas, such as CO₂. Both streams are mixed before entering the bottom of the absorption column to obtain a homogeneous gas mixture. Gas flow rates are measured by independent flowmeters, and the system includes a temperature sensor to monitor the inlet conditions of the gas mixture.

The unit allows the analysis of pressure losses along the packed columns through separate pressure taps, facilitating the evaluation of the hydrodynamic behavior of the gas-liquid system and the characterization of pressure drop as a function of flow rate and packing properties. The unit includes temperature, pressure, and flow sensors in both the gas and liquid circuits, whose values can be visualized and recorded for quantitative study of operating conditions and the development of mass and energy balances.

Настройки cookie

Настройки cookie