QCCC Колонна крекинга, управляемая с компьютера (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

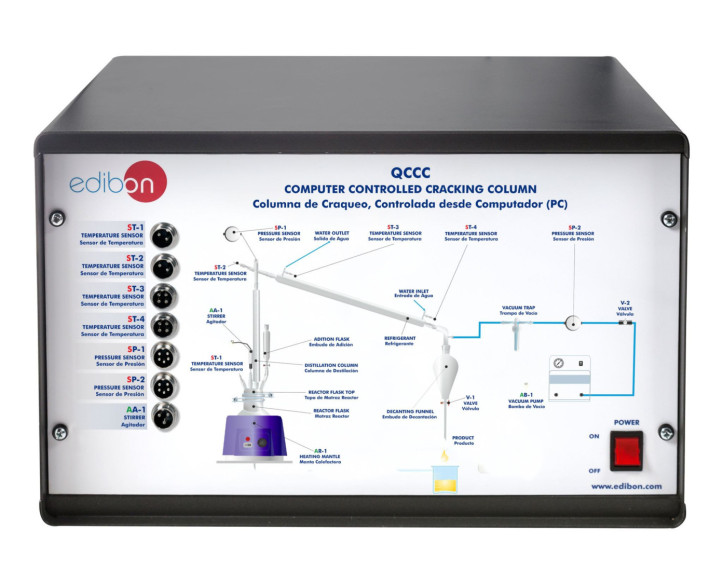

The Computer Controlled Cracking Column, "QCCC", has been designed by EDIBON to cracking and distilling oil is a complete lab tool that allows to the students to carry out a cracking reaction, and the study and the control of different variables that condition it.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

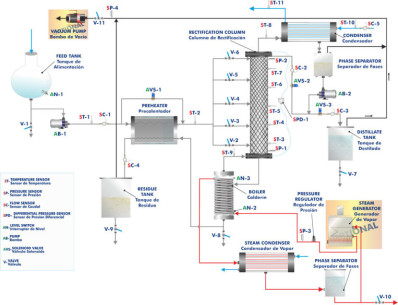

The Computer Controlled Cracking Column, "QCCC", has been designed by EDIBON to cracking and distilling oil is a complete lab tool that allows to the students to carry out a cracking reaction, and the study and the control of different variables that condition it. Also, the production cycle will be completed by means of a separation, purification and analysis of the obtained products in that cracking reaction.

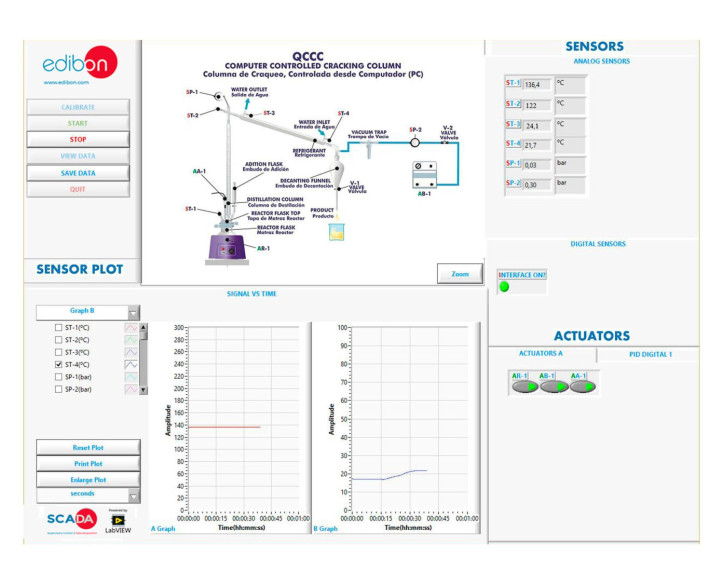

This unit is controlled from a computer. That allows a register of temperature and pressure data and the control of the cracking and distillation processes. Control software is easy and intuitive.

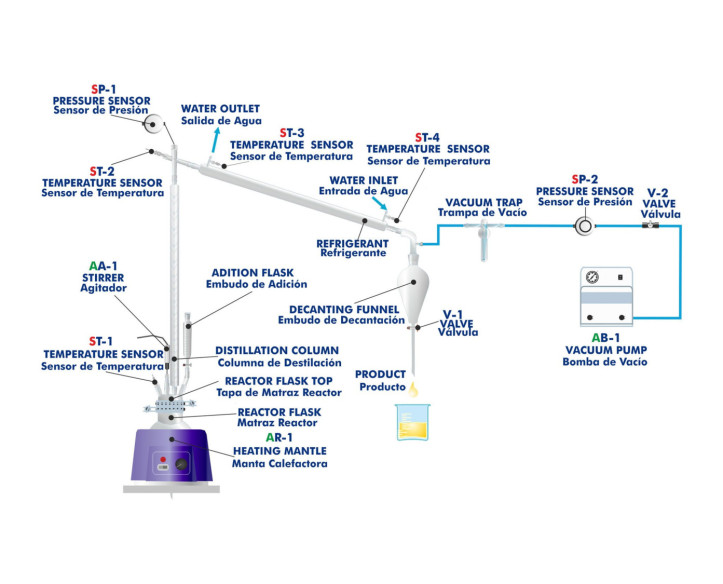

It consists of a glass body, perfectly fixed to an aluminum structure, which allows its handling with complete security, and several systems that allow to control the reaction: stirring, cooling, emptying and heating.

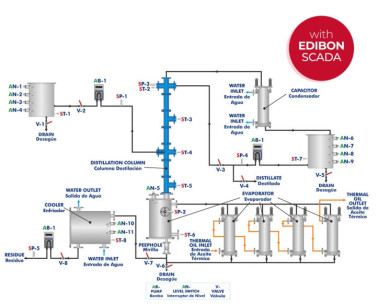

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Carry out cracking reactions.

- Influence of the temperature in the Ricinoleic Acid cracking reaction (gradual increment of temperature).

- Influence of the temperature in the Ricinoleic Acid cracking reaction (sudden increment of temperature).

- Influence of the pressure in the Ricinoleic Acid pyrolysis reaction (working pressure too low).

- Influence of pressure in the Ricinoleic Acid pyrolysis reaction (low working pressure).

- Work with different heating gradients, regulated through the computer.

- Work with different pressures, regulated through the computer.

- Pitch as a catalyst.

- Simple distillation. Separation in its components of the product mixture of cracking.

- Heptanal purification.

- Undecylenic acid purification.

- Application of samples on TLC plates.

- Thin layer chromatography plates analysis.

- Study of several parameters that influence the analysis by thin layer chromatography.

- Other simple practices as calibration of instruments, preparation of samples, etc.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Cleaning the system.

- Monogram of pressure.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QCCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QCCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Дистилляция для Восстановления Коррозионных Растворителей 12 л/ч, Управляемая с Компьютера (ПК) и Сенсорным Экраном

Продвинутое оборудование для непрерывной дистилляции, управляемое компьютером (ПК)

Оборудование непрерывной дистилляции с компьютерным управлением

Оборудование непрерывной дистилляции

Оборудование для периодической дистилляции, управляемое компьютером (ПК)

Оборудование для периодической дистилляции

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie