Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st century, its availability and quality are increasingly at risk. Population growth, industrial and agricultural pollution, water scarcity in vulnerable...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

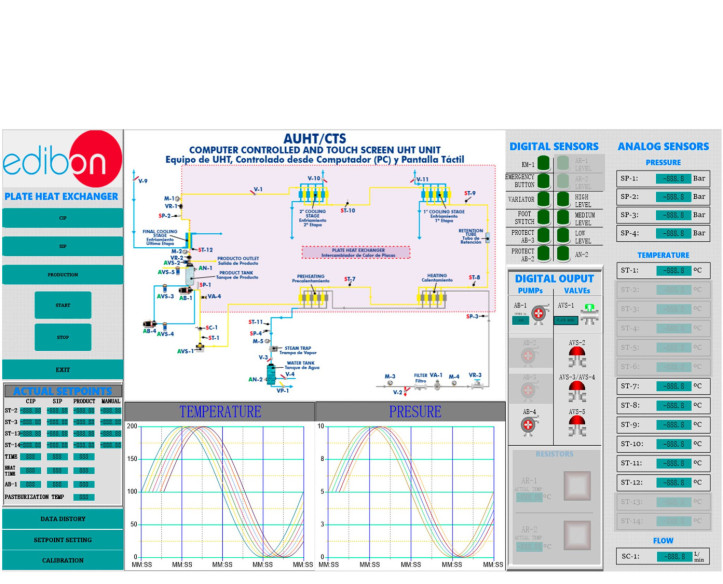

Food Technology is a branch of Food Science based on multidisciplinary knowledge of nutrition, chemical analysis, physics, biochemistry and engineering. Water treatment technologies obtain drinking water, so necessary for our life.

Both disciplines have become in recent years an indispensable...

Настройки cookie

Настройки cookie