At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-CRS 코르크 마개 교육용 스테이션

혁신적인 시스템

관련 뉴스

일반적인 설명

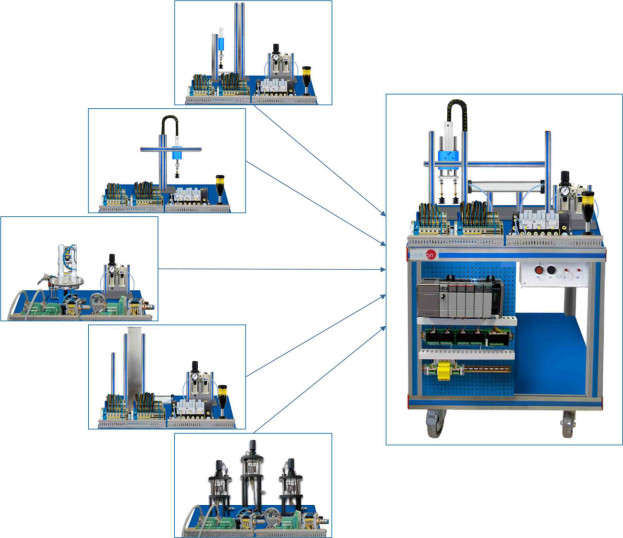

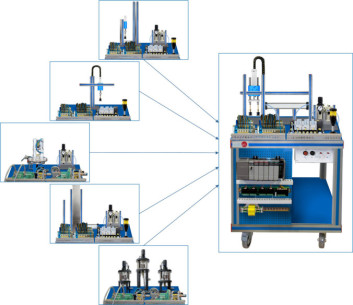

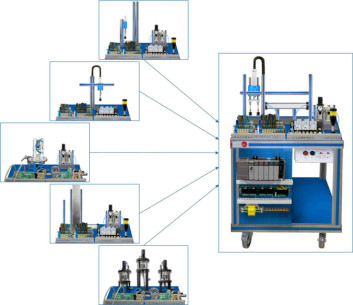

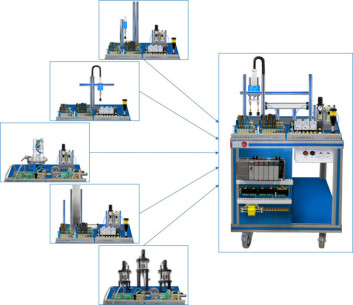

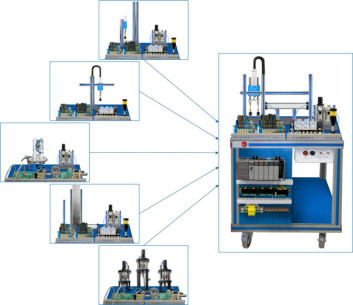

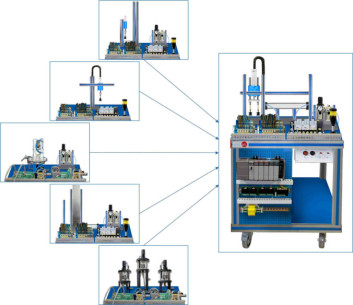

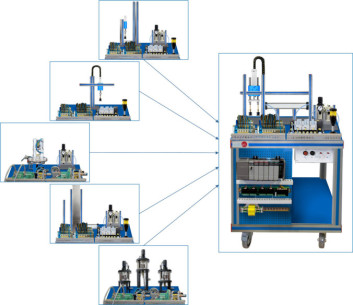

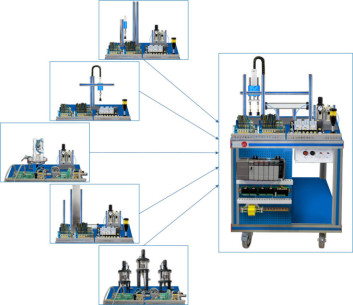

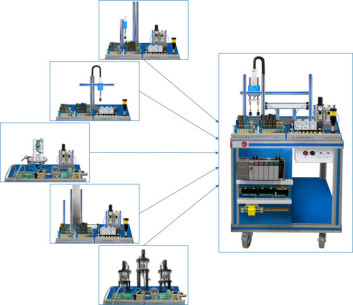

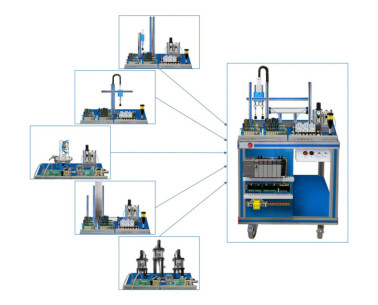

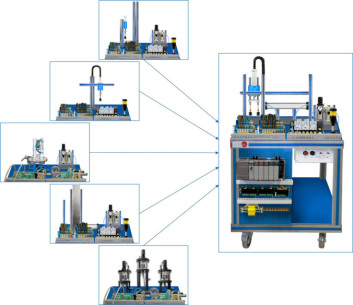

The "AE-PLC-CRS" is a corking system commanded by a PLC. The workstation detects the bottles that arrives on a conveyor belt to the corking position and closes them with a cap using a pressing cylinder. The "AE-PLC-CRS" also includes different sensors in order to check if the amount of liquid in the bottles is correct.

The "AE-PLC-CRS" workstation has been designed as a modular system to facilitate the understanding of the equipment operation:

- The PLC: is composed of an AE-PLCB that contains a HMI device, analog and digital input/output modules, etc, and the required extra modules to put into operation the workstation successfully.

- The control panel: emergency stop push button switch, start/stop button, reset button, light indicator to show the state of the workstation, etc.

- The workstation: is composed of real components used by the industrial automatic conveyor systems such as: capacitive sensors, limit switch sensors, position sensor, etc.

The "AE-PLC-CRS" workstation can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at the "60.-MECHATRONICS, AUTOMATION AND COMPUMECHATRONICS" area.

비슷한 제품

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-FT

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-MS

혼합 교육용 스테이션

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-PHD

펀칭 교육용 스테이션

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-FS

충전 교육용 스테이션

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-APB

캔 개봉 교육용 스테이션

The "AE-PLC-APB" is a bottles opening system commanded by a PLC. The unit is equipped with different containers and a retention system based on a cylinder, in order to allow the Robotic Arm Workstation "AE-BR" or the SCARA Arm Workstation "AE-SCA"...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-M

조립 교육용 스테이션

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-P

자동 프레스 교육용 스테이션

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-AT

자동 나사 조임 교육용 스테이션

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-MEMB

병입 교육용 스테이션

The Bottling Workstation, "AE-PLC-MEMB", designed by EDIBON, is an automatic rotary table with a vessel feeding system, a controlled water filling system, a cap feeder, a vessel closing system, and finally, an extraction system to a complete...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-MET

라벨링 교육용 스테이션

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-ST

드릴링 교육용 스테이션

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-SMOLD

성형 교육용 스테이션

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-SCOR

절단 교육용 스테이션

The Cutting Workstation "AE-PLC-SCOR", designed by EDIBON, is an automatic cutting workstation commanded by a PLC. The "AE-PLC-SCOR" also includes a conveyor system to transport the incoming pieces to the cutting zone where the cutting machine...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-CP

공정 제어 교육용 스테이션

The "AE-PLC-CP" is a process control workstation commanded by a PLC that coordinates the work of 3 industrial controllers that regulates in parallel the level, flow rate, temperature and pressure processes. The "AE-PLC-CP" workstation has been...

보완 장비

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-M

조립 교육용 스테이션

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-P

자동 프레스 교육용 스테이션

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-AT

자동 나사 조임 교육용 스테이션

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-MEMB

병입 교육용 스테이션

The Bottling Workstation, "AE-PLC-MEMB", designed by EDIBON, is an automatic rotary table with a vessel feeding system, a controlled water filling system, a cap feeder, a vessel closing system, and finally, an extraction system to a complete...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-MET

라벨링 교육용 스테이션

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-ST

드릴링 교육용 스테이션

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-SMOLD

성형 교육용 스테이션

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-SCOR

절단 교육용 스테이션

The Cutting Workstation "AE-PLC-SCOR", designed by EDIBON, is an automatic cutting workstation commanded by a PLC. The "AE-PLC-SCOR" also includes a conveyor system to transport the incoming pieces to the cutting zone where the cutting machine...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-FT

여과 교육용 스테이션

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-MS

혼합 교육용 스테이션

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-PHD

펀칭 교육용 스테이션

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- 프로세스 워크 스테이션 애플리케이션

AE-PLC-FS

충전 교육용 스테이션

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정