EFOC Peralatan Fotoelastisitas, Dikendalikan dari Komputer (PC)

SISTEM INOVATIF

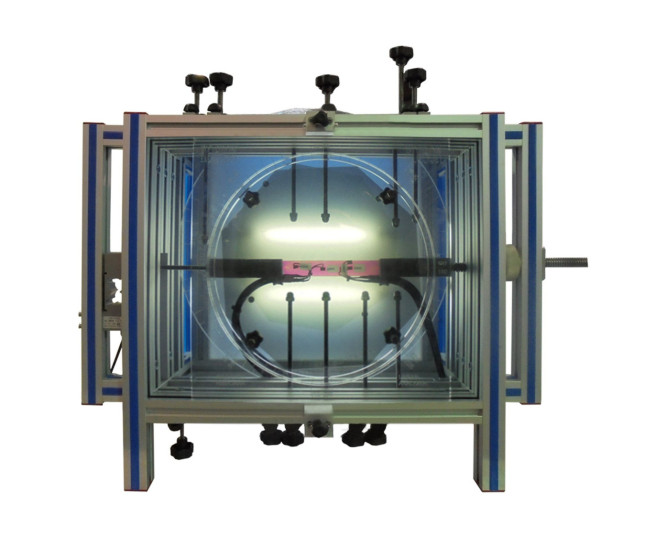

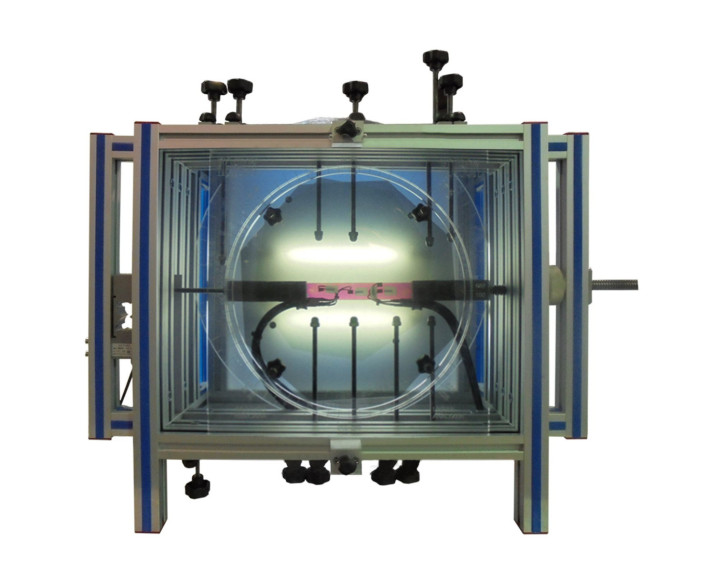

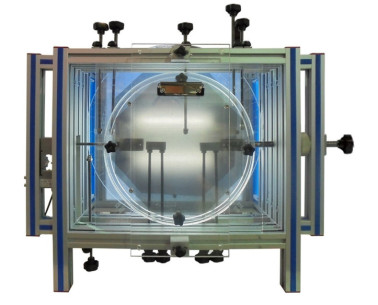

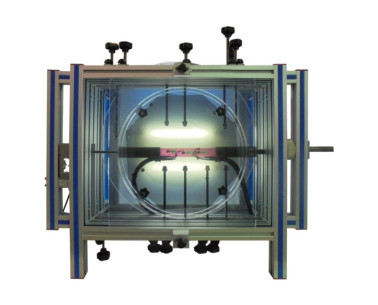

The Computer Controlled Photoelasticity Unit, "EFOC", has been designed by EDIBON for photoelasticity practices, illustrating the subjects of the photoelasticity theory, the elasticity theory, strength of materials, and structure theory.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Computer Controlled Photoelasticity Unit, "EFOC", has been designed by EDIBON for photoelasticity practices, illustrating the subjects of the photoelasticity theory, the elasticity theory, strength of materials, and structure theory.

It is very suitable for the introduction and study of photoelasticity: optical elements, isochromatic, isoclinic, band order, band factor, edge tensionsing, and for strain and stress analysis and measurement with strain gauges.

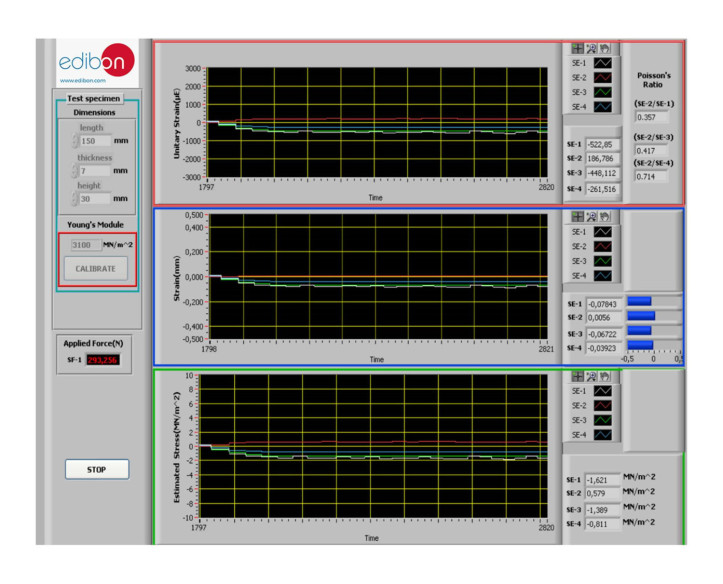

With the aid of the SCADA system it is possible to analyze and process the captured data during test experiments, making measurements with strain gauges.

Using this unit photoelastic experiments and practices of transparent test specimens (models) may be performed.

The different test specimens are subjected to loading by external forces and have poralised light shone through them.

A load application element can apply tensile, bending, compressive, and distributed and punctual loads to the specimen.

The stresses and strains occurring in the test specimen are represented as bright spots or figures of different colours, and we can visualise the distribution of stress.

We offer a wide range of test specimens for making a variety of practices and experiments.

These specimens show a full color and high contrast results and are also made of a special very hard material that avoids breaking during daily use.

The unit includes specimens with strain gauges and the accessories (electronic, mechanical and software) for acquiring all the values in the computer in real time and allows to compare the advantages of one method with the other.

It is also very useful for Young`s module determination of the material and fringe order and band order calculation.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Introduction to photoelasticity: optical elements, isochromatic,isoclinic, band order, band factor, edge tension sign, etc.

- Determination of principal stress difference.

- Isochromatics.

- Illustration of the themes about elasticity, strength of materials and structures using photoelastic tests.

- Pure traction/optical-tensional law.

- Diametrically compressed disc.

- Ring with diametrical compression traction.

- Ring with diametrical compression.

- Plate with circular drill with traction.

- Comparison of the effects from different engraves in piece with traction.

- Pure traction in a piece with section linearly variable.

- Pure flexion.

- Simple flexion.

- Simple flexion, compound beams.

- Compound flexion.

- Compound central core of the section.

- Piece with a great curvature subjected to flexion.

- Arch built-in with a central charge.

- Triangular structure.

- Comparison of the structures.

- Comparison of the effect of different notches.

- Strain and stress analysis and measurements with strain gauges using computer.

- Tardy compensation method (requires EFO-ICL).

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of aprojector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industrieseven to other Technical Education Institutions.

- Visualization of all the sensors values used in the EFOC unit process.

- Several other exercises can be done and designed by the user.

PERALATAN SIMILAR TERSEDIA

Peralatan Fotoelastisitas dengan Sistem Penglihatan Buatan, Dikendalikan dari Komputer (PC)

Peralatan Demonstrasi Fotoelastis Tegangan

PERALATAN KOMPLEMENTER

Peralatan Fotoelastisitas

Peralatan Fotoelastisitas dengan Sistem Penglihatan Buatan, Dikendalikan dari Komputer (PC)

Peralatan Pelatihan Strain Gauge

Peralatan untuk Penentuan Faktor Strain Gauge

Peralatan Demonstrasi Fotoelastis Tegangan

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie