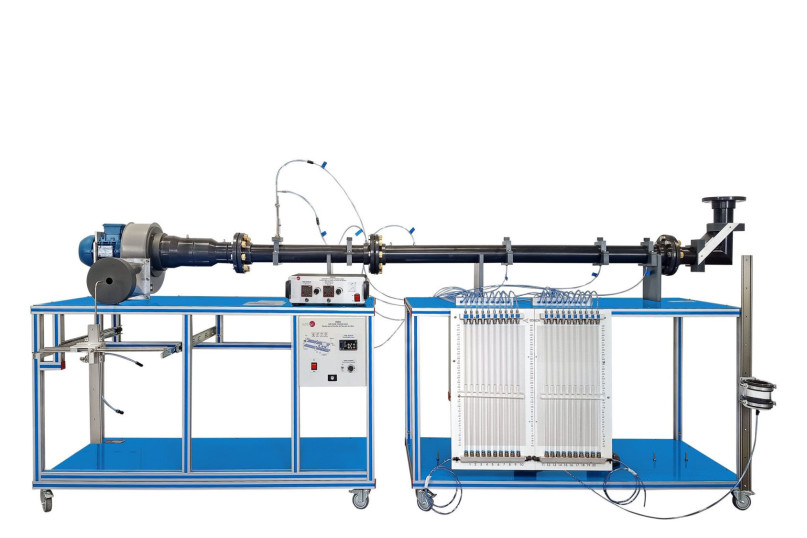

HECA Air Flow Studies Unit

INNOVATIVE SYSTEMS

The Air Flow Studies Unit, "HECA", designed by EDIBON, allows to study the basic principles of fluid mechanics that are applied to analyze the air flow in order to determine the pressure distribution and the velocity profile of a flow.

Laboratories

RELATED NEWS

General Description

The Air Flow Studies Unit, "HECA", designed by EDIBON, is a floor standing unit that allows to measure different characteristics of air distribution systems and to demonstrate certain basic principles of fluid mechanics in ducts and jets.

The unit is mounted on a metal frame with wheels and consists of two modules connected one to each other.

One module includes an electrical centrifugal fan, with speed control.

The other module includes a long and smooth test pipe that is connected to the suction side of the centrifugal fan. A deflector in the inlet prevents air separation from the wall of the pipe and reduce the formation of vortices, and the pipe diameter minimizes the presence of turbulence. Several pressure tappings are included along the length of the pipe to determine the pipe friction factor, pressure losses and velocity profiles.

The unit has two Pitot tubes:

- One located at the discharge of the fan, attached and properly protected. It can be situated at different distances from the discharge orifice to study free jet velocity profiles.

- The other one can be located in any of the different points of the test tube to perform an air flow analysis of the velocity profile inside the pipe section. This Pitot tube can also be located at different distances in the pipe to demonstrate the boundary layer growth.

The air flow rate can be measured with various measuring devices, such as iris diaphragm, a Pitot tube, an orifice plate and two nozzles with different diameters.

The unit includes two bends and an angle to fit to the pipe for comparison of pressure losses.

The measuring devices and the Pitot tubes are connected via tubes to a multi-tube inclinable manometer where the pressure differences can be measured. This manometer can be inclined to increase its resolution and can be locked into different positions.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Utilization of manometers to measure pressure drops.

- Measurement of air flow rate with an iris diaphragm.

- Measurement of air flow rate with a Pitot tube.

- Measurement of air flow rate with an orifice plate.

- Measurement of air flow rate with a nozzle.

- Determination of pressure losses in straight pipes.

- Determination of pressure losses in pipe bends and angles.

- Determination of the velocity profile in a pipe which air is flowing.

- Determination of the velocity profile in a free jet with the Pitot tube.

- Demonstration of the boundary layer growth.

- Understanding the use of Reynolds’ numbers.

- Measuring the air flow via a Venturi nozzle (requires the additional recommended element HECA-1).

- Determination of the exact section of the Venturi tube. Study of Bernoulli’s Theorem (requires the additional recommended element HECA-1).

- Study of the velocity profile above a flat plate (requires the optional accessory HECA-2).

- Study of the boundary layer on a flat plate (requires the additional recommended element HECA-2).

- Study of the drag forces in different shapes. (requires the additional recommended element HECA-3).

SUPPLEMENTARY EQUIPMENT

Fluid Friction in Pipes Unit, with Hydraulics Bench (FME00)

Fluid Friction in Pipes Unit, with Basic Hydraulics Feed System (FME00/B)

Fluid Friction in Pipes Unit

Computer Controlled Pipe Network Unit, with Hydraulics Bench (FME00)

Pipe Network Unit, with Hydraulics Bench (FME00)

Pipe Network Unit, with Hydraulics Bench (FME00/B)

Mesh in Pipe Unit

Unit to Study the Pressure Drop of Compressible Fluids in Pipes

Computer Controlled Water Hammer Unit

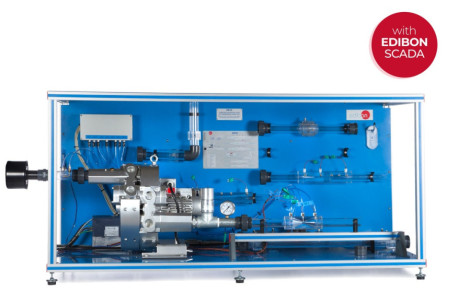

Computer Controlled Flow of Compressible Fluids Unit

Computer Controlled Unit for Transient Drainage Processes in Storage Reservoirs

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences