The Chemical Reactors, "QR", has been designed by EDIBON for the study and comparison of different types of chemical reactors in an easy and simple way and thus allowing, on a small scale, to carry out the necessary studies and practices to understand the operation of the reactors.

These reactors allow for the comparison of different types of chemical reactors, and with each type of reactor, the study of the influence of reaction temperature and residence time is enabled, thanks to the thermostatic bath, two 1 l tanks, and two regulation pumps of up to 3 l/min included in the supply.

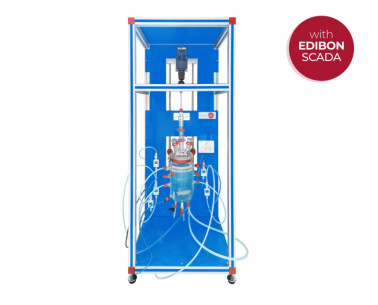

The Service Unit for QR, "QUS", provides the necessary elements for the operation of the different reactors. It performs the following functions:

- Reagent supply: consisting of two 1 liter pyrex containers each located at the back, two dosing pumps and all the necessary connections.

- Temperature control: consisting of a thermostatic bath and an impulsion pump.

- Quick and easy to perform reactor exchange and positioning system.

- This unit allows feeding reagents and temperature control of reactors with a volume up to 1.5 l.

Required elements (at least one) (Not included):

- QRCA. Continuous Stirred Tank Reactor for QR.

The Continuous Stirred Tank Reactor for QR, "QRCA", designed by EDIBON, provides a controlled environment for detailed kinetic study of homogeneous liquid-liquid chemical reactions. This type of reactor, also known as CSTR (Continuous Stirred-Tank Reactor), is characterized by having the reactants in a tank where they are constantly stirred.

Through a series of practices, it allows for the determination of ionic conductivity, obtaining the reaction order with respect to different compounds, calculating rate constants, formulating rate equations, and analyzing the variation of kinetics with temperature. Additionally, it offers the possibility to compare theoretical and experimental results, study mixing effects, and perform operations both in batch and continuous modes. With the ability to calibrate temperature and conductivity sensors, the "QRCA" is a comprehensive and versatile unit for training and research in chemical engineering, contributing to the advancement of knowledge in this field.

To work with this reactor, the Base and Service Unit, "QUS", is required, which supplies the necessary reagents and thermostatic water for proper operation.

- QRT. Tubular Flow Reactor for QR.

The Tubular Flow Reactor for QR, "QRT", has been designed by EDIBON to conduct the kinetic study of homogeneous liquid-liquid reactions. In this unit, a continuous stream of reactants is passed through, which mix and react as they flow through the unit.

This unit allows for a wide range of practices, including determining kinetic equations, calculating constants, and comparing theoretical and experimental values of reactor conversion. Additionally, it enables the study of residence time effects and mixing effects on chemical reactions.

To work with this reactor, the Base and Service Unit, "QUS", is required, which supplies the necessary reagents and thermostatic water for proper operation.

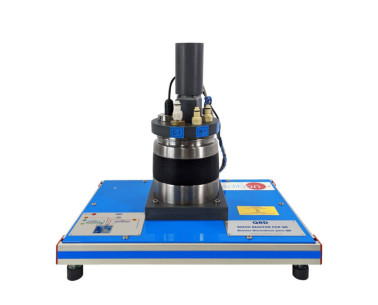

- QRD. Batch Reactor for QR.

The Batch Reactor for QR, "QRD", designed by EDIBON, enables the study and kinetic analysis of homogeneous liquid-liquid reactions, as well as the demonstration of adiabatic and isothermal reactions.

This unit offers a wide range of opportunities for investigating reaction kinetics, ranging from sensor calibration to the formulation of velocity equations and the determination of ionic conductivities. Its ability to operate in both batch and continuous modes facilitates detailed analysis of effects such as mixing, variation of kinetic constants with temperature, and comparison of theoretical and experimental data.

Moreover, the discontinuous reactor is ideal for studying various chemical reactions, such as chemical synthesis, precipitation, neutralization, and oxidation-reduction. It also allows for demonstrating the impact of different reaction parameters, such as reactant concentration, temperature, and reaction time. Especially in adiabatic reactions, where there is no heat transfer with the surroundings, the adiabatic discontinuous reactor ensures ideal conditions for studying reactions in detail.

To work with this reactor, the Base and Service Unit, "QUS", is required, which supplies the necessary reagents and thermostatic water for proper operation.

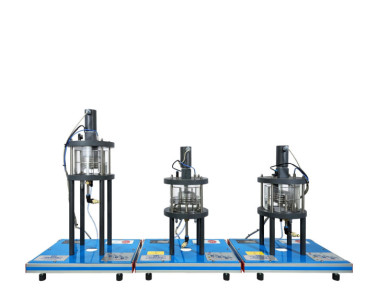

- QRS. Stirred Tank Reactors in Series for QR.

The Stirred Tank Reactors in Series for QR, "QRS", designed by EDIBON, are versatile units for the kinetic study of liquid-liquid homogeneous reactions. This type of reactor allows the outlet flow from one reactor to become the inlet flow for another, optimizing processes and enabling flexible experimentation with one, two, or three reactors, facilitating a comprehensive understanding of the process.

These reactors enable a wide variety of practices, such as temperature sensor calibration, determination of ionic conductivities, and simulation of different reactor configurations. With the ability to operate with one or up to three reactors in series, in continuous mode and with mixing effects, the "QRS" facilitates detailed analysis of the effects of reaction parameters on chemical kinetics, thus contributing to the advancement of knowledge in this field.

To work with this reactor, the Base and Service Unit, "QUS", is required, which supplies the necessary reagents and thermostatic water for proper operation.

- QRL. Laminar Flow Reactor for QR.

The Laminar Flow Reactor for QR, "QRL", designed by EDIBON, allows determining the kinetic equations of various reactions, such as the basic hydrolysis of ethyl acetate, and calculating key kinetic constants. Laminar flow reactors, a variant of tubular reactors, are characterized by the movement of fluids in parallel layers with a constant velocity and without significant turbulence. Additionally, the Laminar Flow Reactor for QR, "QRL" is particularly used for demonstrating flow patterns and studying step disturbances for flow characterization and conversion in steady state.

This reactor facilitates the comparative analysis between theoretical and experimental conversion values, contributing to enhancing the understanding of chemical transformation processes. It is also used to investigate the effect of variables such as flow rate and feed concentration on steady-state conversion, as well as to study the influence of temperature on laminar flow characterization.

Through visual techniques, such as color tracer tracking, the reactor’s response to different disturbances can be observed, providing valuable information on system behavior under variable conditions. In summary, the laminar flow reactor offers a versatile and precise platform for research and development in the field of chemical engineering and fluid dynamics.

To work with this reactor, the Base and Service Unit, "QUS", is required, which supplies the necessary reagents and thermostatic water for proper operation.

- QRP. Plug Flow Reactor for QR.

The Plug Flow Reactor for QR, "QRP", designed by EDIBON, allows studying and investigating the kinetics of reactions and flow behavior in chemical systems. A plug flow reactor is a type of tubular reactor that assumes the assumption of no axial mixing of components along its length. This type of reactor requires the application of a series of specific formulas over a volume differential instead of over the total volume, as is the case with perfectly mixed reactors. This reactor enables the determination of key kinetic equations, such as the basic hydrolysis of ethyl acetate, which is fundamental for the design and optimization of industrial processes.

It facilitates comparative analysis between theoretical and experimental conversion values, enhancing understanding of chemical processes. Additionally, it examines the effect of flow rate and feed concentration on reaction efficiency and selectivity. Its ability to investigate the influence of temperature on laminar flow characterization is essential for optimizing chemical processes under variable conditions. Furthermore, it studies the reactor’s response to disturbances, such as pulses and step changes, providing vital information for the design and control of industrial chemical processes.

In summary, the piston flow reactor enables a wide range of practices and experiments, making it an invaluable tool for researchers, educators, and industry professionals seeking to understand and optimize complex chemical processes.

To work with this reactor, the Base and Service Unit, "QUS", is required, which supplies the necessary reagents and thermostatic water for proper operation.

쿠키 기본 설정

쿠키 기본 설정