The Batch Distillation Unit, "UDDB", designed by EDIBON, allows the practical and detailed study of the batch distillation process, widely used in the chemical industry for separating liquid mixtures containing components with different boiling points. Through its design, the unit facilitates understanding of the principles governing mass and energy transfer during the distillation operation, allowing observation of how process variables directly affect the composition of both the distillate and the residue.

The batch distillation process is characterized by the introduction of the feed into the boiler at the beginning of the operation, with separation taking place sequentially until the desired composition is achieved or the process is completed. This type of distillation is fundamental in applications where production is not continuous, or when high product purity is required. Therefore, studying this process is essential to understand the relationship between temperature, pressure, reflux ratio, and the composition of vapor and liquid along the column.

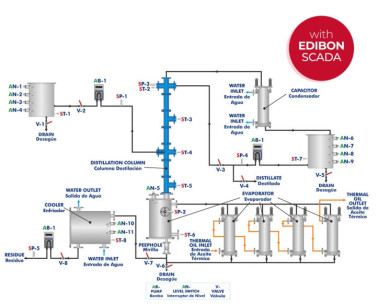

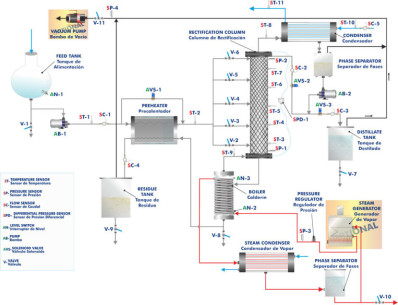

The "UDDB" consists of a stainless steel boiler that serves as a reboiler for the liquid mixture, on which different types of interchangeable columns can be mounted. This feature allows the comparison of performance and behavior of various column configurations within the same equipment. A standard eight-plate column is included, enabling the study of distillation in discrete stages, as well as a packed column, which allows the analysis of continuous mass transfer operation. In this way, it is possible to evaluate the advantages and characteristics of both column types.

Additionally, to expand experimental possibilities, several optional accessories can be incorporated:

- Raschig Rings Column, "CAR1", for studying distillation in packed columns.

- 8-Bubble Cap Tray Column (1 Temperature Sensor), "C8P1", for analyzing the basic behavior of a tray column.

- 10-Bubble Cap Tray Column (10 Temperature Sensors), "C10P10", for a more detailed analysis of temperature profiles.

- 14-Bubble Cap Tray Column (14 Temperature Sensors), "C14P14", designed for advanced studies of efficiency and mass transfer.

At the top of the column, a total condenser is located to liquefy the rising vapor. The cooling water flow is regulated by a valve and measured with a flowmeter, allowing precise control of condensation conditions. The condensate is directed to a reflux system that enables adjustment of the ratio between the liquid returning to the column and the one collected as distillate. This reflux control is essential to study the vapor-liquid equilibrium and its influence on product purity and composition.

The unit includes temperature sensors strategically placed at key points (boiler, column head, condenser inlet and outlet), allowing the recording of thermal profiles during operation and real-time process monitoring. In addition, the pressure drop along the column can be determined using a differential manometer, which helps to understand the effects of vapor flow and friction on separation efficiency.

쿠키 기본 설정

쿠키 기본 설정