EBMC Оборудование для переработки биомассы, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

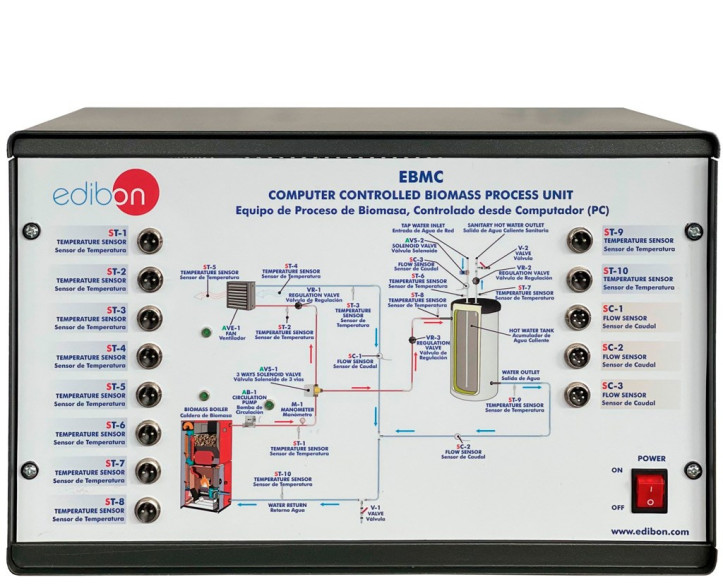

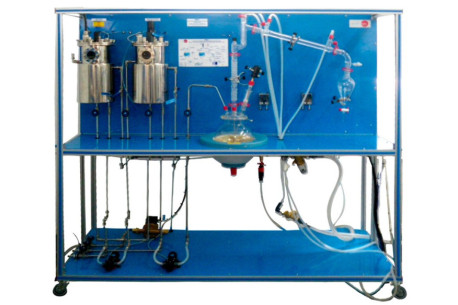

The Computer Controlled Biomass Process Unit "EBMC", designed by EDIBON, is a unit that allows the user to study heating systems and how to obtain domestic hot water with a biomass boiler.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

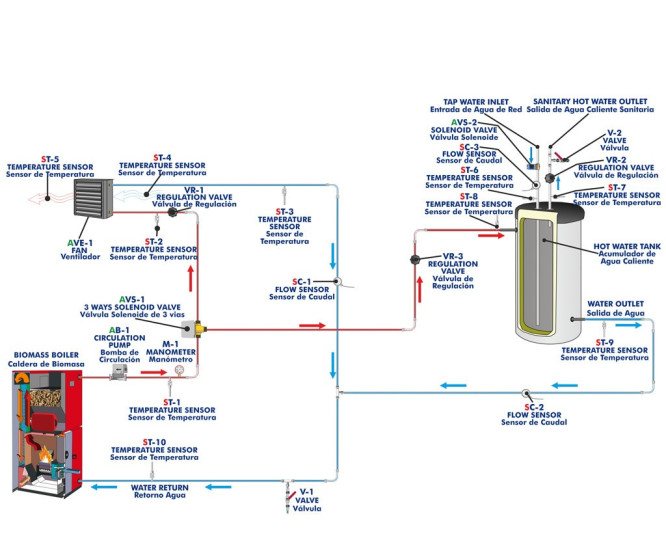

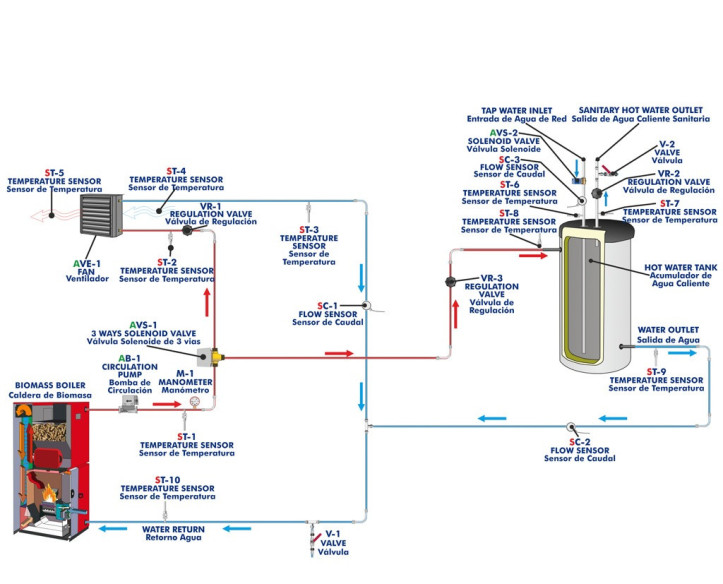

The main element of the unit is the biomass boiler, which will heat the water that will flow through the other components transferring its heat.

The boiler is a biomass boiler of 16 kW that works with pellet and other granulated fuels. The body of the boiler is made of steel with a thickness of 5 mm that guarantees a long operating life. It includes a burner made of high temperature stainless steel with self-cleaning system, which allows the use of several granulated fuels apart from Pellet.

The boiler has ashes extraction boxes, besides it facilitates the access to cleaning and maintenance areas.

The boiler heats water that is impelled by a computer controlled circulating pump through the circuit.

The unit also includes a computer controlled three-ways solenoid valve that distributes the water heated by the biomass boiler towards two primary circuits: one towards the double jacket of the storage tank to obtain domestic hot water and the other towards the unit heater to generate heating.

This valve, when activated, allows the passage of water towards both directions. On the other hand, when deactivated, it closes the water passage towards the unit heater and increases the water flow towards the hot water storage tank.

The capacity of the storage tank is 60 l and it is made of AISI 316 Ti stainless steel. This material has an excellent behavior against corrosion and high temperatures. It has a double jacket through which the water previously heated in the boiler flows, constituting the primary circuit. There is a computer controlled solenoid valve, located in the tap water inlet line towards the storage tank to be heated, that will be opened or closed according to the requirements.

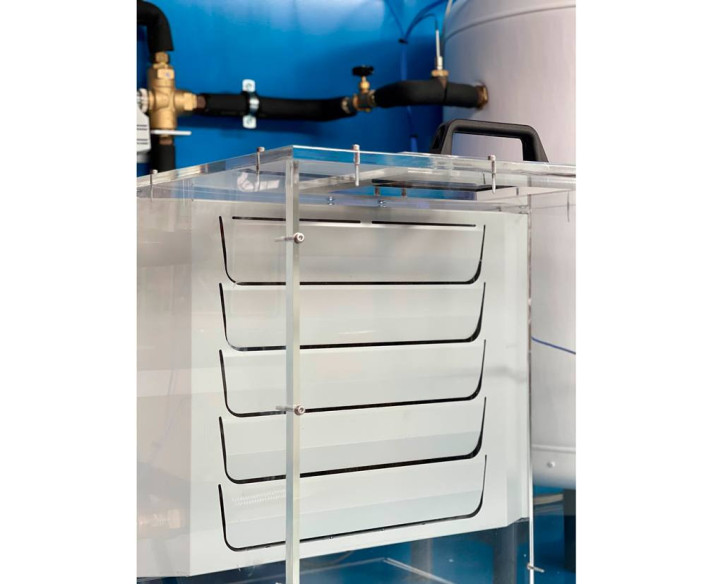

The part of the unit where the heating generation is studied is formed by a computer controlled unit heater, located inside a PMMA box.

It allows the student to control the time required to heat the box up to the required temperature. The temperature control of that box is possible thanks to a PID control via software that acts on the three-ways solenoid valve.

The primary circuit is closed with the recycling of both the water from the circuit that has already given its heat in the storage tank and the water leaving the unit heater. Both lines are joined and enter the boiler again, thus closing the primary circuit.

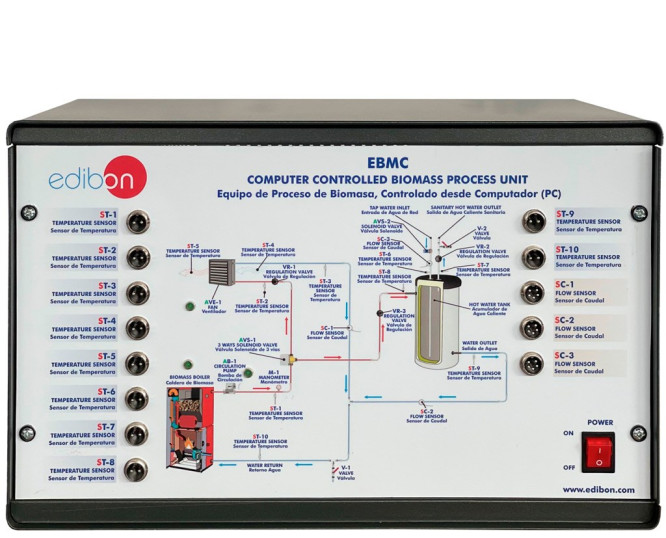

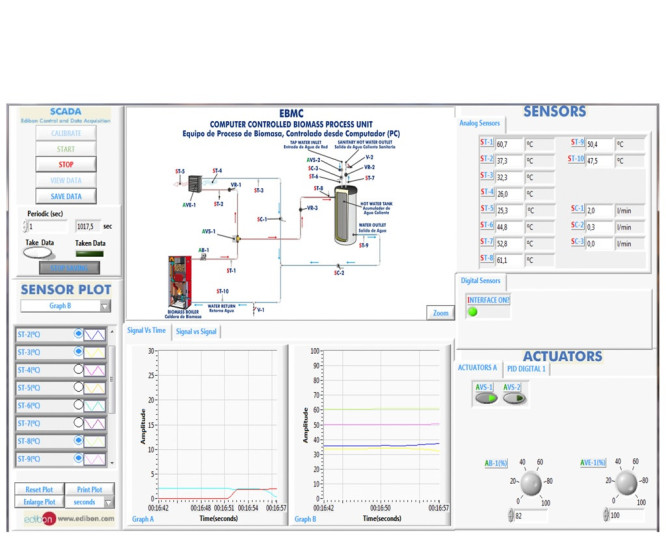

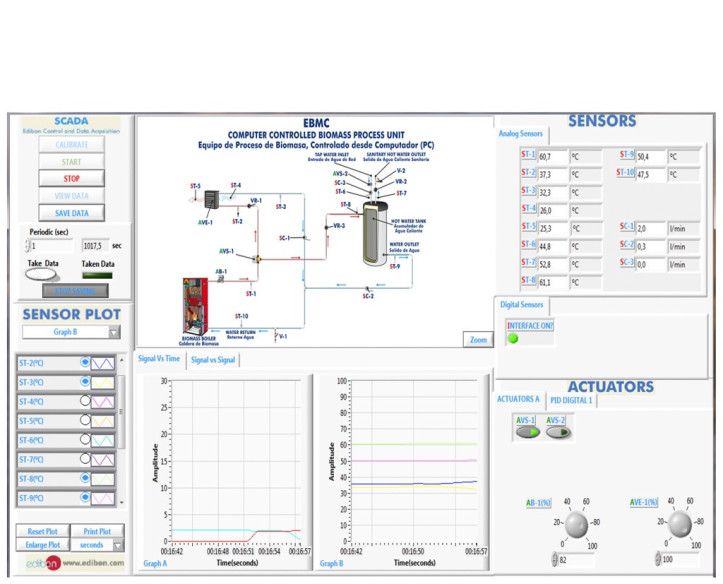

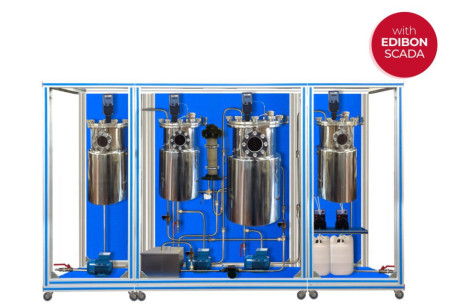

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Familiarization with the operation of a heating and DHW system with biomass boilers.

- Start-up of a biomass boiler.

- Energy balance in the heating circuit (unit heater) with different types of biomass fuels.

- Energy balance in the sanitary water circuit with different types of biomass fuels.

- Influence of the heating water flow variation in the heat transfer.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Determining the inlet and outlet temperature of the heating water.

- Determining the temperature of the domestic hot water.

- Measurement of the heat transfer of different biomass fuels to the heating water.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EBMC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EBMC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Полуконтинентальный центробежный сепаратор объемом 60 л, управляемый с ПК и сенсорного экрана

Полуконтинентальный центробежный сепаратор объемом 1000 л, управляемый с ПК и сенсорного экрана

Оборудование для производства биоэтанола, управляемое компьютером (ПК)

Оборудование для производства биоэтанола

Установка по переработке биогаза, управляемая компьютером (ПК) и сенсорным экраном

Оборудование для производства биогаза, управляемое компьютером (ПК)

Оборудование для производства биогаза

Оборудование для производства биодизеля, управляемое компьютером (ПК)

Оборудование для производства биодизеля

Оборудование для переработки биомассы

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie