PBOC 멀티펌프 테스트 스탠드 (4가지 펌프 유형), 컴퓨터(PC) 제어

혁신적인 시스템

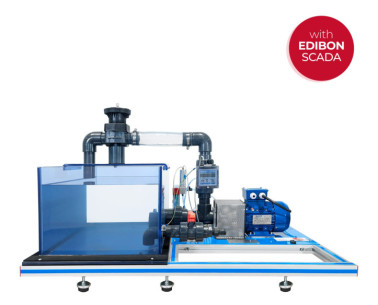

The Computer Controlled Multipump Testing Bench (4 types of pumps), "PBOC", designed by EDIBON, allows the students to study the operating characteristics of several types of pumps.

확장

실험실

관련 뉴스

일반적인 설명

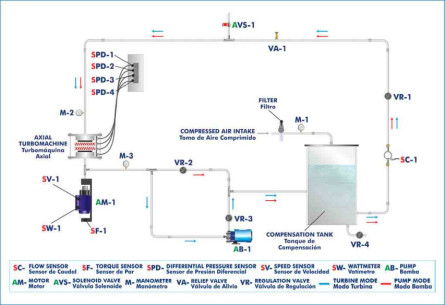

The Computer Controlled Multipump Testing Bench (4 types of pumps), "PBOC", designed by EDIBON, allows the students to study the operating characteristics of several types of pumps. This unit allows to control and to measure the most representative parameters of the pumps.

The measurements that can be taken using the unit are: admission and discharge pressure of the pump, impelled water flow, torque and turning speed of the pump and the manometric height, the hydraulic and mechanic power and the efficiency can be determined.

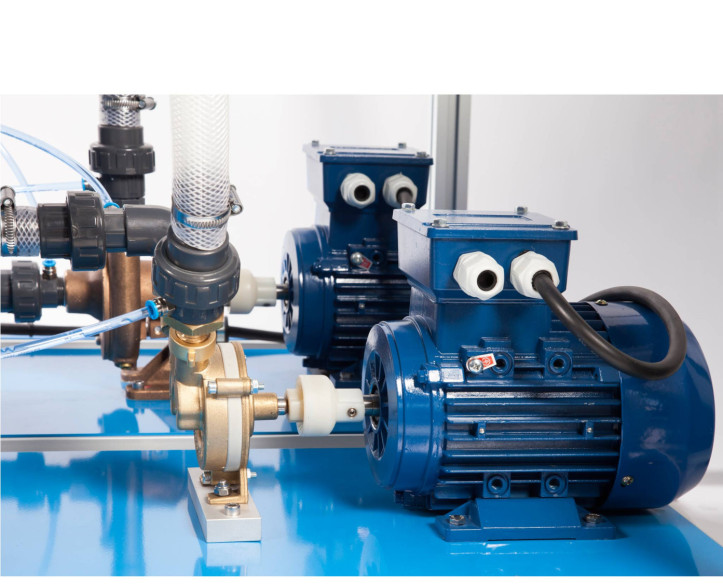

The unit is mounted on a structure with a working surface covered by a plastic sheet. Two different parts can be distinguished in the unit: the pumps, with their motors, connections and flexible hoses and the tanks to store and recycle water, with their measuring elements.

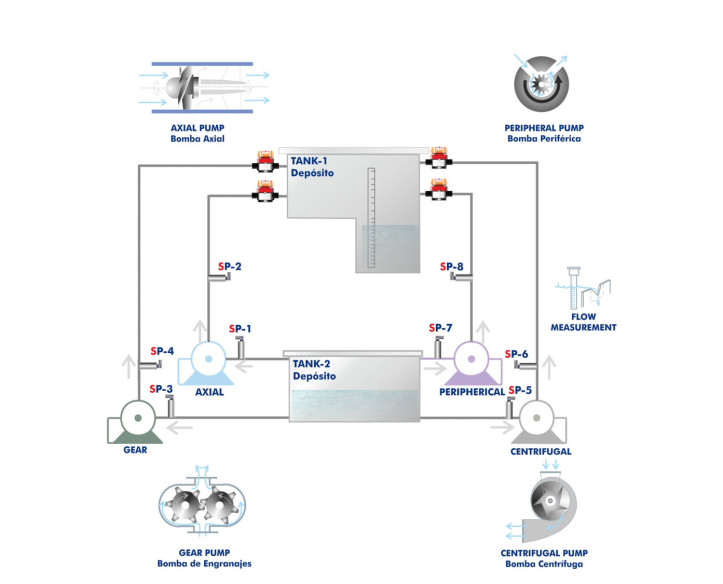

The minimum supply includes four types of pumps: one centrifugal pump, one axial flow pump, one gear pump and one peripheral pump. There are several optional pumps (not included in the minimum supply) that can be connected to the unit through valves and flexible hoses in order to demonstrate the operating behavior of these pumps.

Each pump is activated by a separate motor that allows the direct measurement of the torque. The speed is changed by a frequency converter, located in the control interface box, and computer controlled.

The pump under study impels water in a closed circuit. There are two pressure tappings in each pump, one at the admission and other at the discharge of the pump, to determine the manometric head of the different pumps. These tappings are connected to their corresponding pressure sensor.

The pumps included in the minimum supply are connected through flexible hoses to the volumetric tank and to the storage tank. The connection of the optional pumps to the volumetric tank and the storage tank are done through valves, connections and flexible hoses.

The unit includes two tanks, located at different levels, to recycle the water. The upper volumetric tank, located just over the water storage tank, is equipped with two weirs and two stilling baffles and includes a discharge valve and an activator.

The volumetric tank has been designed to accommodate low or high flows and it includes a level sensor to determine the water flow and the water level in the volumetric tank, an indicating transparent tube and a graduated scale. It has a safety overflow system that directly pours water into the storage tank if an incorrect use is made. The storage tank includes an indicating transparent tube.

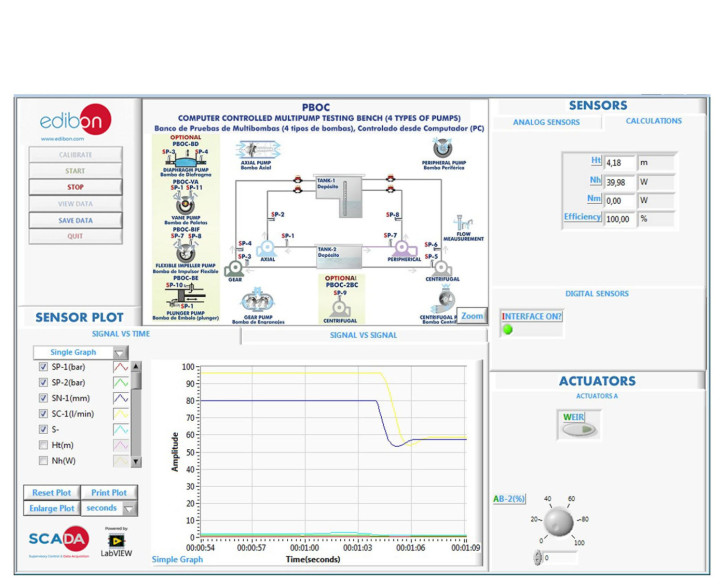

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Determination of the flow by a weir of thin wall in U-shape.

- Determination of discharge coefficient of a weir of thin wall in U-shape.

- Determination of the curve Q vs r.p.m. of the centrifugal pump.

- Determination of the curve Q vs r.p.m. of the peripherical pump.

- Determination of the curve Q vs r.p.m. of the gear pump.

- Determination of the curve Q vs r.p.m. of the axial pump.

- Determination of the curve H vs Q for different r.p.m. of the centrifugal pump.

- Determination of the curve H vs Q for different r.p.m. of the peripherical pump.

- Determination of the curve H vs Q for different r.p.m. of the gear pump.

- Determination of the curve H vs Q for different r.p.m. of the axial pump.

- Determination of the mechanical power vs flow for different r.p.m. of the centrifugal pump.

- Determination of the mechanical power vs flow for different r.p.m. of the peripherical pump.

- Determination of the mechanical power vs flow for different r.p.m. of the gear pump.

- Determination of the mechanical power vs flow for different r.p.m. of the axial pump.

- Determination of the curve η vs the flow for different r.p.m. of the centrifugal pump.

- Determination of the curve η vs the flow for different r.p.m. of the peripherical pump.

- Determination of the curve η vs the flow for different r.p.m. of the gear pump.

- Determination of the curve η vs the flow for different r.p.m. of the axial pump.

- Determination of the map of a centrifugal pump.

- Determination of the map of a peripherical pump.

- Determination of the map of a gear pump.

- Determination of the map of an axial pump.

- Determination of the adimensional characteristic curves for different types of pumps.

- Determination of the specific speed of different types of pumps.

- Verification of the similarity rules for pumps of different geometry.

장비로 수행 할 수있는 더 많은 실용적 연습

- Sensors calibration.

Additional practical possibilities to be done with the Recommended elements: (Not included)

Second Centrifugal Pump (PBOC-2BC):

- Coupling in series of two centrifugal pumps of different characteristics.

- Coupling in series of two centrifugal pumps with the same characteristics.

- Parallel coupling of two centrifugal pumps with similar characteristics.

- Parallel coupling of two centrifugal pumps of different characteristics.

Flexible Impeller Pump (PBOC-BIF):

- Determination of the curve Q vs r.p.m. of the flexible impeller pump.

- Determination of the curve H vs Q for different r.p.m. of the flexible impeller pump.

- Determination of the mechanical power vs flow for different r.p.m. of the flexible impeller pump.

- Determination of the curve η vs the flow for different r.p.m. of the flexible impeller pump.

- Determination of the map of a flexible impeller pump.

Diaphragm Pump (PBOC-BD):

- Determination of the curve Q vs r.p.m. of the diaphragm pump.

- Determination of the curve H vs Q for different r.p.m. of the diaphragm pump.

- Determination of the mechanical power vs flow for different r.p.m. of the diaphragm pump.

- Determination of the curve η vs the flow for different r.p.m. of the diaphragm pump.

- Determination of the map of a diaphragm pump.

Plunger Pump (PBOC-BE):

- Determination of the curve Q vs r.p.m. of the plunger pump.

- Determination of the curve H vs Q for different r.p.m. of the plunger pump.

- Determination of the mechanical power vs flow for different r.p.m. of the plunger pump.

- Determination of the curve η vs the flow for different r.p.m. of the plunger pump.

- Determination of the map of a plunger pump.

Vane Pump (PBOC-VA):

- Determination of the curve Q vs r.p.m. of the vane pump.

- Determination of the curve H vs Q for different r.p.m. of the vane pump.

- Determination of the mechanical power vs flow for different r.p.m. of the vane pump.

- Determination of the curve η vs the flow for different r.p.m. of the vane pump.

- Determination of the map of a vane pump.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PBOC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PBOC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

비슷한 제품

보완 장비

Computer Controlled Multipump Testing Bench (2 types of pumps)

Computer Controlled Series/Parallel Pumps Bench

Series/Parallel Pumps Bench

Computer Controlled Gear Pump Bench

Computer Controlled Axial Pump Bench

Computer Controlled Piston Pump Bench

Computer Controlled Axial Flow Turbomachines Unit

펌프 연구 및 시험 벤치

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정