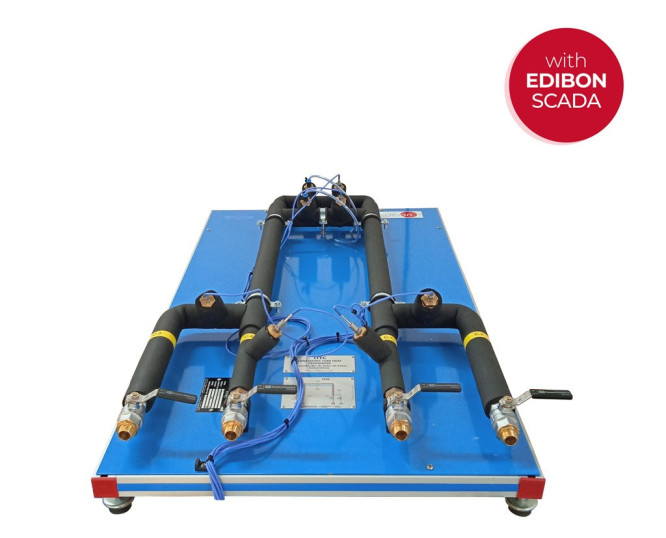

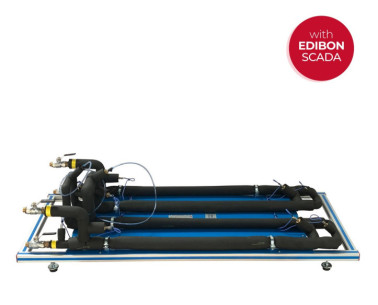

TITC Concentric Tube Heat Exchanger for TICC

혁신적인 시스템

The Concentric Tube Heat Exchanger for TICC, "TITC", designed by EDIBON, allows for the study of heat transfer between two fluids: the hot water flowing through the inner tube and the cold water flowing through the annular zone between the inner and outer tubes. This unit enables analysis of how heat transfer varies under different conditions, such as changes in flow rate, temperature, and flow type (counterflow or parallel flow).

확장

실험실

관련 뉴스

일반적인 설명

The Concentric Tube Heat Exchanger for TICC, "TITC", designed by EDIBON, allows for the study of heat transfer between two fluids: the hot water flowing through the inner tube and the cold water flowing through the annular zone between the inner and outer tubes. This unit enables analysis of how heat transfer varies under different conditions, such as changes in flow rate, temperature, and flow type (counterflow or parallel flow).

A concentric tube heat exchanger allows for the study and analysis of heat transfer between two fluids flowing through concentric tubes, one inside the other. This includes investigating the efficiency of the heat exchanger, studying the effectiveness of heat exchange, the influence of flow rate on heat transfer, and comparing different flow configurations, such as counterflow and parallel flow.

Additionally, this unit allows for the development of specific practices to determine the overall energy balance in the heat exchanger, calculate the effectiveness of the heat exchanger using the NTU method, and study the influence of Reynolds number on heat transfer.

In summary, the TITC offers students, teachers, and researchers the opportunity to understand and practice the fundamental principles of heat transfer and its application in the industry.

To work with this unit, the Base and Service Unit, "TIUS", is required, which provides key functions such as heating water using a thermostatic bath, pumping hot water, regulating and measuring the flow rates of cold and hot water, measuring the inlet and outlet temperatures of cold and hot water, as well as measuring the pressure drop in the heat exchanger.

These Computer Controlled Units are supplied with EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Global energy balance in the heat exchanger and the study of losses.

- Exchanger effectiveness determination. NTU Method.

- Study of the heat transfer under counter-current and co-current flow conditions.

- Flow influence on the heat transfer. Reynolds number calculation.

- Sensors calibration.

장비로 수행 할 수있는 더 많은 실용적 연습

- Study of the hysteresis of the flow sensor.

Additional practical possibilities:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TICC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TICC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

비슷한 제품

Plate Heat Exchanger for TICC

Shell & Tube Heat Exchanger for TICC

Jacketed Vessel Heat Exchanger for TICC

Coil Vessel Heat Exchanger for TICC

Extended Concentric Tube Heat Exchanger for TICC

Extended Plate Heat Exchanger for TICC

Cross Flow Heat Exchanger for TICC

보완 장비

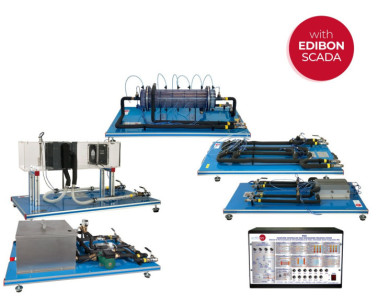

Computer Controlled Heat Exchangers Training System

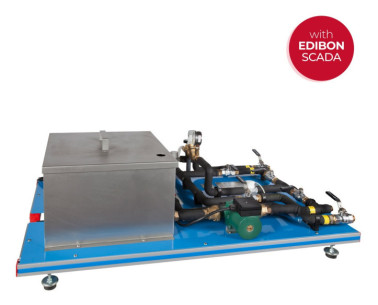

Base Service Unit (Common for all available Heat Exchangers type "TI")

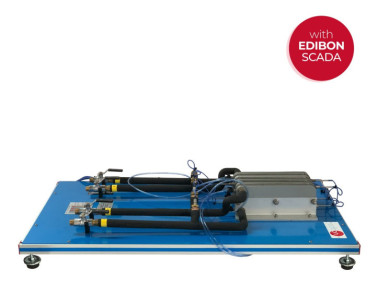

Extended Concentric Tube Heat Exchanger for TICC

Plate Heat Exchanger for TICC

Extended Plate Heat Exchanger for TICC

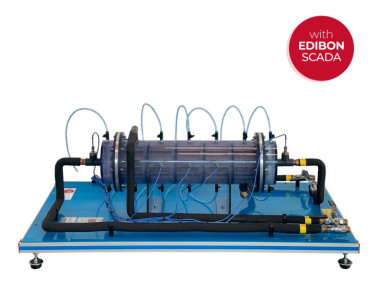

Shell & Tube Heat Exchanger for TICC

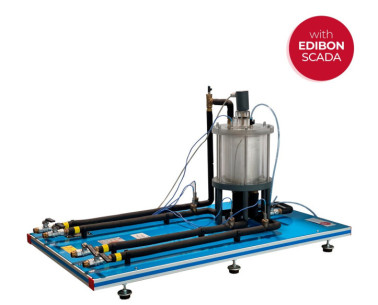

Jacketed Vessel Heat Exchanger for TICC

Coil Vessel Heat Exchanger for TICC

Turbulent Flow Heat Exchanger for TICC

Cross Flow Heat Exchanger for TICC

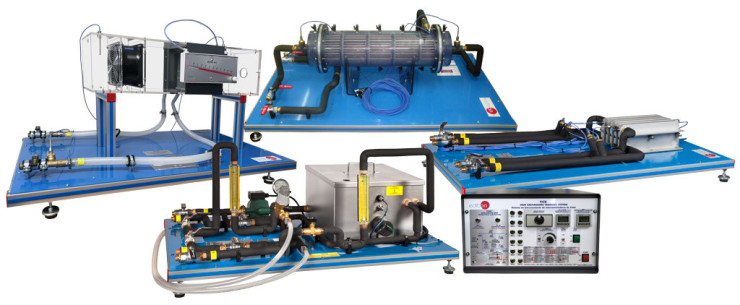

Heat exchanger Training System

Base Service Unit (Common for all available Heat Exchangers type "TI..B")

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정