TIFCC Computer Controlled Cross Flow Heat Exchanger

INNOVATIVE SYSTEMS

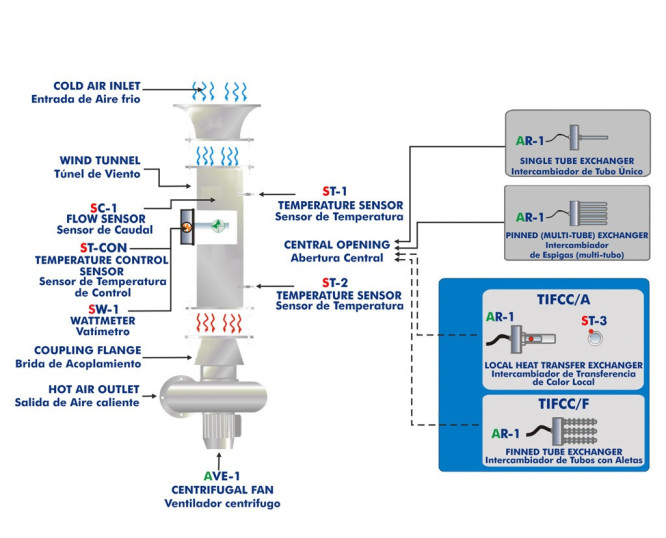

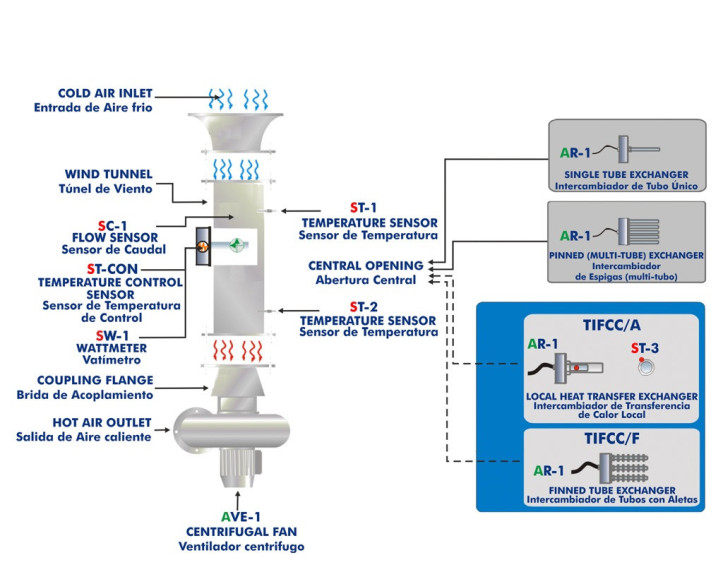

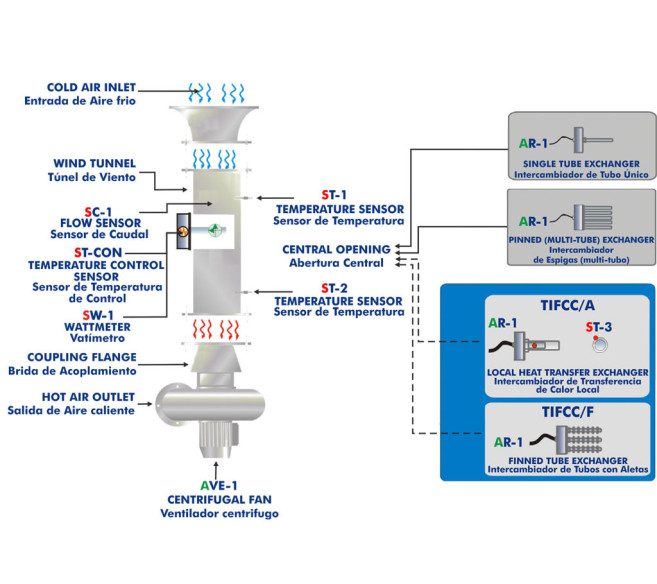

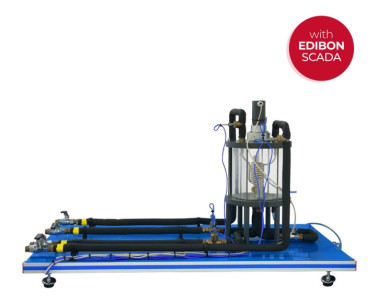

The Computer Controlled Cross Flow Heat Exchanger, "TIFCC", consists of a rectangular wind tunnel made of stainless steel, resistant to corrosion. It has a bell-shaped inlet and a central opening arranged longitudinally with two supporting elements made of stainless steel to retain the plates with the different exchangers.

Expansions

Laboratories

RELATED NEWS

General Description

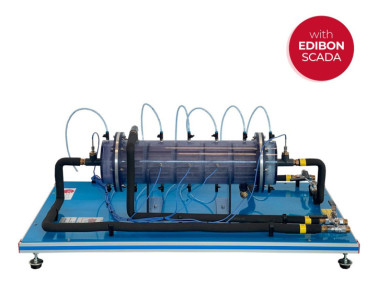

The Computer Controlled Cross Flow Heat Exchanger (TIFCC) basically consists of a rectangular wind tunnel made of stainless steel, resistant to corrosion. It has a bell-shaped inlet and a central opening arranged longitudinally with two supporting elements made of stainless steel to retain the plates with the different exchangers.

The tunnel is installed over the inlet of a powerful centrifugal fan and connected to it by an elastic coupling flange. This fan aspirates air from the tunnel and expels it outside, making air flow along the tunnel. There is a variable speed drive to control the air flow through the tunnel with the fan control through the computer.

The TIFCC unit includes two types of exchangers: a pinned (multi-tube) exchanger and a single tube exchanger, where the heating element is lodged, which is controlled through the computer.

To perform all the practical exercises the unit has two temperature sensors to measure the air temperature in the tunnel, before and after passing through the heat exchanger, a control temperature sensor lodged in the heating element and a flow sensor that allows the user to determine the air flow along the tunnel.

Available two optional exchangers: Local Heat Transfer Exchanger (TIFCC/A) and Finned Tube Exchanger (TIFCC/F).

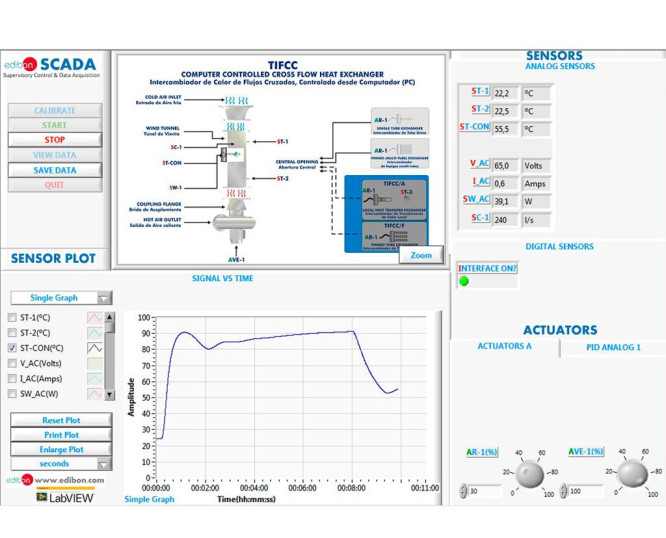

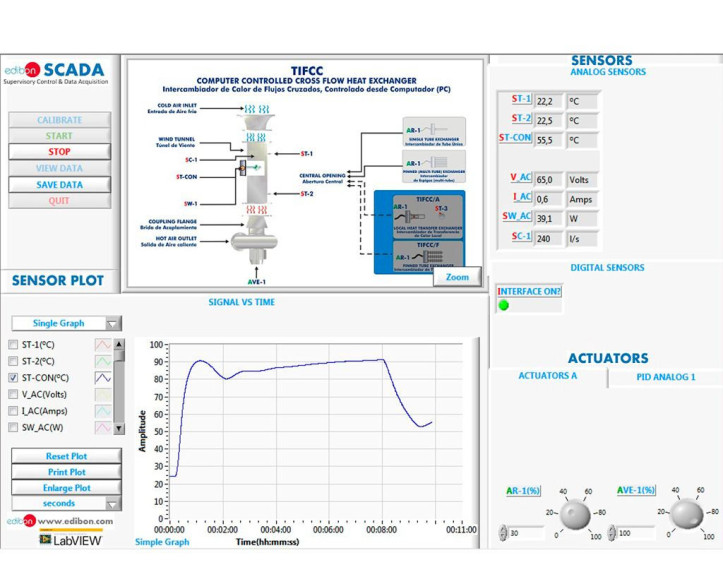

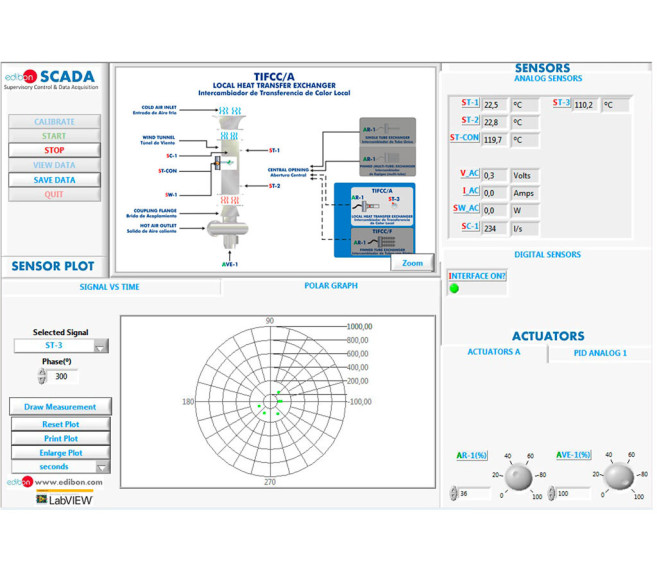

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Investigation of convective processes.

- Determination of heat transfer in a single tube exchanger.

- Determination of heat transfer in a pinned (multi-tube) exchanger.

- Determination of the average heat transfer in a pinned (multitube) exchanger.

- Deduction of the relationship between Nusselt, Reynolds and Prandtl numbers.

- Sensors calibration.

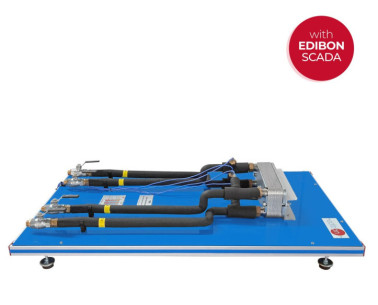

Practical possibilities with the optional TIFCC/A exchanger:

- Determination of the existing relationship between Nusselt and Reynolds number using the direct heat transfer element.

- Determination of the local variation in the convective heat transfer coefficient, using the direct heat transfer element.

Practical possibilities with the optional TIFCC/F exchanger:

- Effect produced by the external fins in the heat transfer process.

- Determination of the heat transfer in a finned tube exchanger.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TIFCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TIFCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Base Service Unit (Common for all available Heat Exchangers type "TI")

Concentric Tube Heat Exchanger for TICC

Extended Concentric Tube Heat Exchanger for TICC

Plate Heat Exchanger for TICC

Extended Plate Heat Exchanger for TICC

Shell & Tube Heat Exchanger for TICC

Jacketed Vessel Heat Exchanger for TICC

Coil Vessel Heat Exchanger for TICC

Turbulent Flow Heat Exchanger for TICC

Cross Flow Heat Exchanger for TICC

Heat exchanger Training System

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences