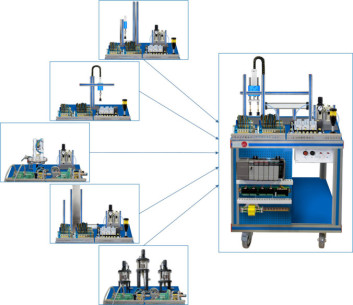

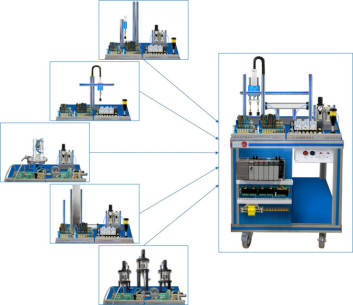

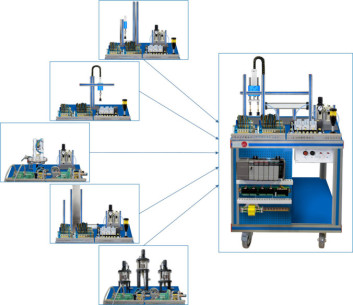

The "AE-PLC-MR1" is an automatic rotary table with a feeder, quality control and mounting system integrated into it. The "AE-PLC-MR1" has a vertical storage, the system provides pieces one by one to the rotary table, then, a quality control system checks that the piece has the correct dimensions. Finally, if the piece is appropriated, is mounted inside another piece. If the piece has not the correct dimensions is discarded by the rotary table.

The "AE-PLC-MR1" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU limit and all extra modules needed to perform a corrent working of the workstation and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, the pressure components, the filters and regulators to assure the appropriate working of the unit.

- The workstation: it is composed by real industrial components used by the rotary table systems such as reed sensors, presence sensors, DC motor, inductive sensors, rotary table with 8 positions, etc.

The "AE-PLC-MR1" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

Preferensi cookie

Preferensi cookie