TSPC Computer Controlled Saturation Pressure Unit

SISTEM INOVATIF

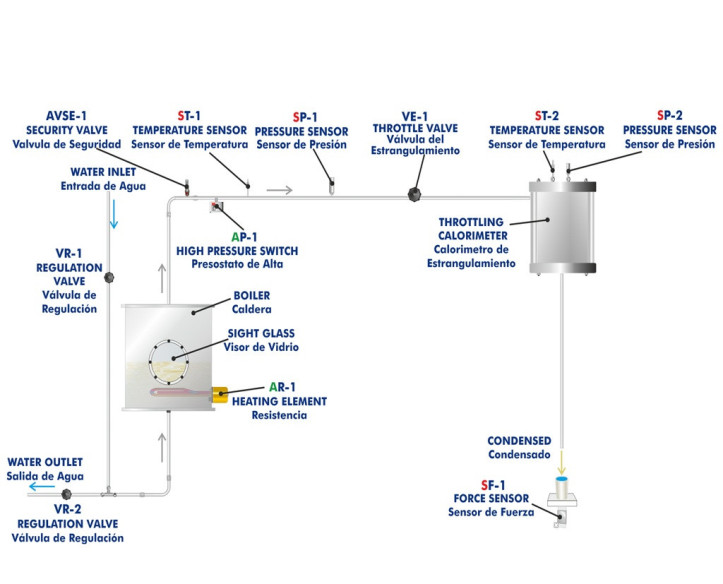

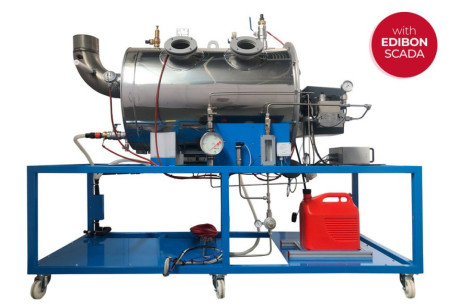

The Computer Controlled Saturation Pressure Unit, "TSPC", consists of a water boiler, including a computer controlled immersion heating element, and a sight glass to observe the boiling patterns in the water surface and control the water level in the boiler.

Ekspansi

Laboratorium

GAMBARAN UMUM

The Computer Controlled Saturation Pressure Unit, "TSPC", consists of a water boiler, including a computer controlled immersion heating element, and a sight glass to observe the boiling patterns in the water surface and control the water level in the boiler.

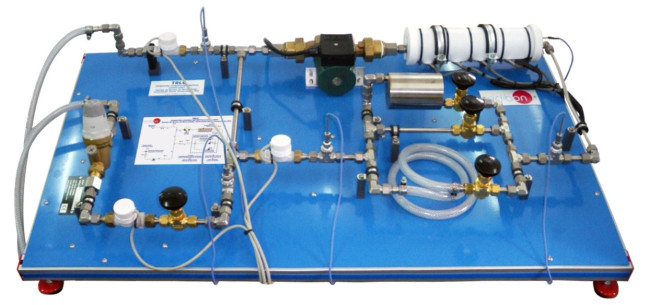

The saturated steam formed in the boiler passes through a throttle valve and is expanded to atmospheric pressure in a throttling calorimeter with the purpose of determining the dryness fraction of the saturated steam.

The temperature and pressure are measured after the boiler to determine the properties of the saturated steam, and after the expansion in the throttling calorimeter. In addition, a force sensor measures the weight of the condensed water.

The unit includes all the safety measures required for a safe operation, such as relief valve and pressure switch to limit the working pressure, and transparent protection panels.

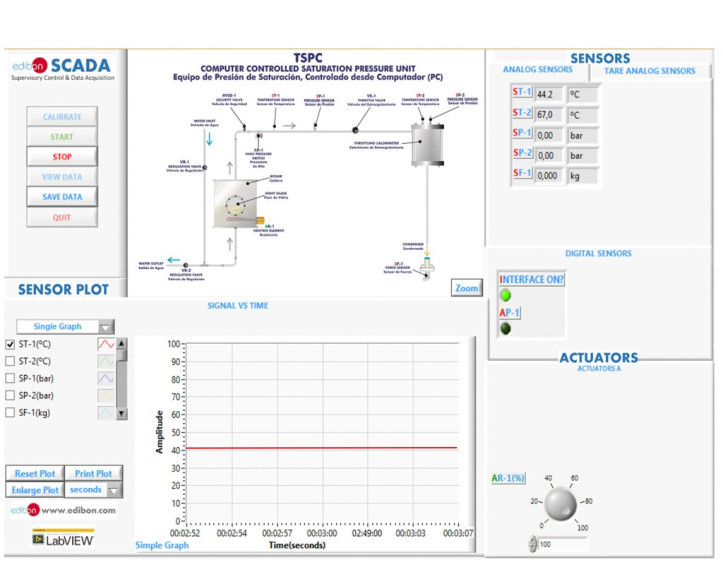

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Measurement of the relationship between temperature and pressure of the saturated vapour in the outlet of the boiler.

- Understanding the origin and use of steam tables.

- Understanding saturation curves.

- To study the characteristics of a two phase fluid.

- Using a throttling calorimeter to determine the quality of wet steam.

Saturation Loop:

- Observation of the patterns of boiling at the surface of the water.

- Measurement of the temperature of saturated steam over the range of pressures 0 to 8 bar gauge.

- Comparison of the saturation curves obtained with those published in steam tables.

- Determination of the describing equation and linearisation.

- Study the concept of the saturation line.

- Determination of the percentage of error between experimental and theoretical data.

- Effect of the rate of response on the accuracy of the measurement.

- To study the characteristic behavior of a two phase fluid.

- Gauge and absolute pressures.

- Temperature scales.

Throttling Calorimeter:

- Determination of the dryness fraction (quality of the steam) produced by the saturation pressure unit at different operating pressure.

- Use of steam tables.

- Use of the steady flow energy equation.

- Study the difference in enthalpy between phases - enthalpy of vaporization.

Other practical possibilities:

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TSPC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TSPC unit process.

- Several other exercises can be done and designed by the user.

PERALATAN KOMPLEMENTER

Thermal Expansion Training Unit

Computer Controlled Expansion Processes of a Perfect Gas Unit

Bomb Calorimeter

Computer Controlled Separating and Throttling Calorimeter

Computer Controlled Marcet Boiler Unit

Computer Controlled Temperature Measurement Unit

Temperature Measurement Unit

Temperature Measurement Training Unit

Computer Controlled Gas Laws Unit (Boyle and Gay-Lussac Laws)

Computer Controlled Recycle Loops Unit

Recycle Loops Unit

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie