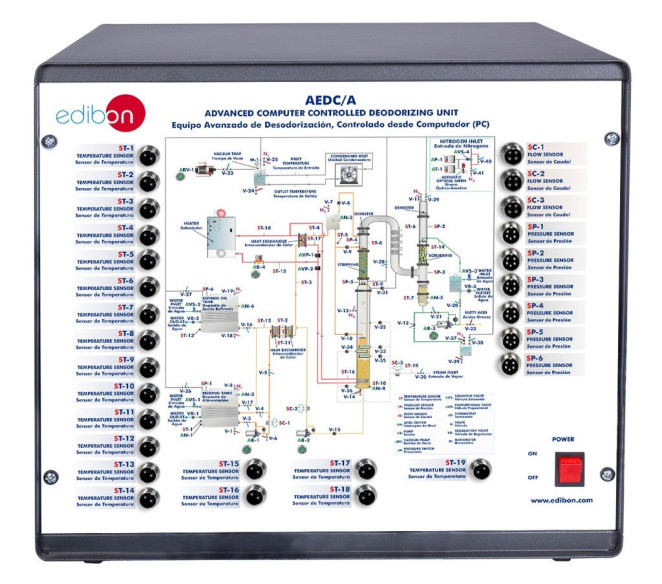

The Advanced Computer Controlled Deodorizing Unit, "AEDC/A", designed by EDIBON is a unit that allows the study and research of the continuous deodorization operation capable of performing a vacuum and high temperature distillation with steam.

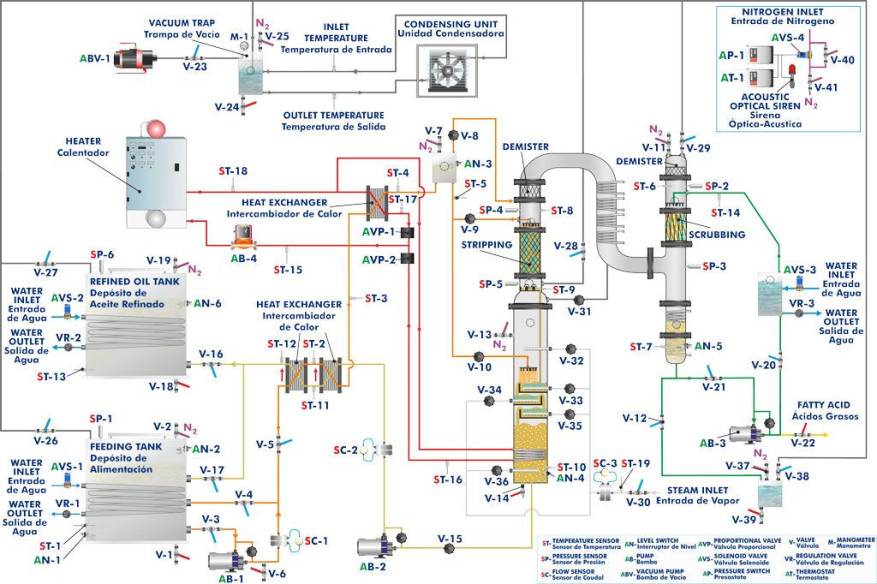

In the deodorization process, natural fatty acids (GFA) are removed from different types of vegetable oils, allowing the study of the main factors that influence the process.

The main element is the column that has structured filling and trays, to carry out the separation of fatty acids (stripping), also to wash the gases generated (scrubbing) has another structured filling fraction. After each operation, two demisters separate the liquids in the form of small particles contained in vapors and gases by coalescence.

The feed to the column is distributed evenly through collectors. To improve the exchange of material, superheated steam is injected into the column. The extracted fatty acids are recirculated through the head of the column to avoid cooling and therefore solidification and the possibility of clogging the ducts. Thermal oil circulates through the column’s coil, providing the necessary energy to keep the vegetable oil warm for the necessary residence time until the deodorization stage is completed. Along the column there are sensors that record the temperature and pressure at the different heights of the column.

Heat exchangers are used to provide the necessary thermal jump to the typical deodorisation temperature of the specific vegetable oil.

The feed tank allows the oil to be deodorised to be stored as well as being de-aerated and heated to suit the process conditions.

The refined oil tank stores the oil that has been deodorised for subsequent analysis.

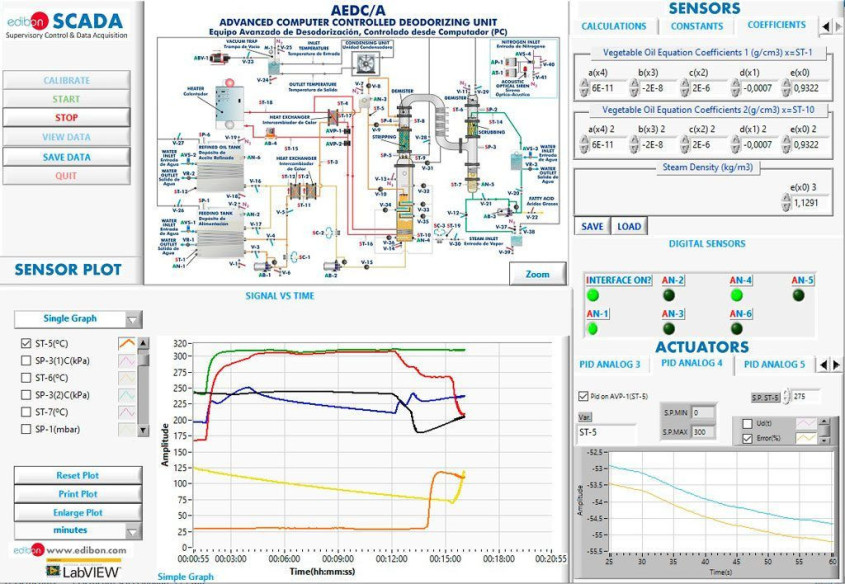

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Preferensi cookie

Preferensi cookie