Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of Fluid Mechanics and learn about #fluids properties. #DiscoverEdibon #Engineering.

PDDRC Gerät für transiente Abflussvorgänge in Speicherbecken, computergesteuert.

INNOVATIVE SYSTEME

The Computer Controlled Unit for Transient Drainage Processes in Storage Reservoirs, "PDDRC", allows to simulate transient drainage processes between storage reservoirs and the operation of a surge chamber.

Erweiterungen

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Unit for Transient Drainage Processes in Storage Reservoirs, "PDDRC", allows to investigate transient drainage processes in storage reservoirs, to simulate a rainwater retention basin and to study the operation of a surge chamber.

The unit includes two reservoirs and a transparent surge chamber. The upper reservoir includes an adjustable weir and the lower reservoir includes an overflow and a drainage line with two valves. The surge chamber is installed in this line. The drainage line of the surge chamber includes a gate to generate water hammers.

The water inlet line to the upper reservoir includes a computer controlled pump, a valve to regulate the inlet flow and a flow sensor. The overflow and the surge chamber include two drains.

The unit allows to study three different configurations and several experiments: consecutive storage reservoirs, rainwater retention basin and surge chamber.

In the first configuration, the transient drainage processes are shown in two storage reservoirs, where the lower reservoir is behind the upper reservoir. The upper reservoir simulates a storage reservoir, where the adjustable weir is used as a free overfall. The lower reservoir simulates a storage reservoir with overflow.

The delayed drainage processes can be studied in the "rainwater retention basin" configuration. The upper reservoir simulates a drainage channel with a gate, which is simulated with the adjustable weir. The lower reservoir simulates a rainwater retention basin and the discharge is adjusted by using two valves in the drainage line.

A water hammer is produced in the "surge chamber" configuration by rapidly closing the gate in the drainage pipe. The oscillation can be seen as a pendulum movement of the water level in the surge chamber.

The water level in the two reservoirs and the water level fluctuations in the surge chamber are measured by three pressure sensors. These measurements allow to represent the pressure curves and course of the water levels.

The unit includes a protective cover to prevent spillages.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the main drainage processes between storage reservoirs.

- Demonstration of transient drainage processes in two consecutive storage reservoirs.

- Determination of discharge in two consecutive storage reservoirs.

- Demonstration of transient drainage processes in a rainwater retention basin.

- Measure of the oscillations of the surge chamber.

- Measure of the natural frequency of the surge chamber.

- Measure of the water level fluctuations.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PDDRC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PDRRC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

8.9.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

PVFA

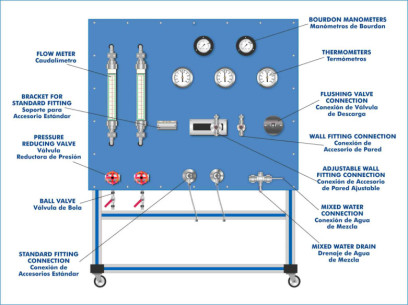

The Pipes, Valves and Fittings Assembly Unit, "PVFA", designed by EDIBON, consists of a solid and rigid U-shaped frame where a series of real pipes and fittings are mounted to form a complete hydraulic system. A filter, a sight glass and a...

8.9.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

BFPT

Backflow Prevention Training Unit

The Backflow Prevention Training Unit, "BFPT", allows verifying the operation of multiple non-return devices. The system contains the most common backflow prevention devices used in the industry. The main objective is to recognize each element...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TEV3V

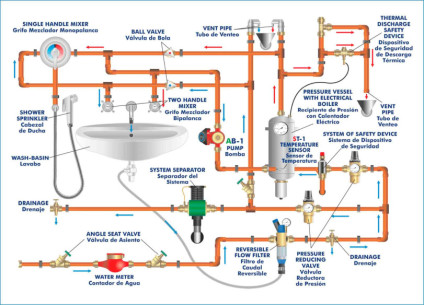

Three-Way Mixing Valve Training Unit

The Three-Way Mixing Valve Training Unit, "TEV3V", allows to demonstrate the function of a three-way mixing valve in a hot water heating system. The three-way mixing valve in the heating system regulates the supply water temperature to a heating...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TEV4V

Four-Way Mixing Valve Training Unit

The Four-Way Mixing Valve Training Unit, "TEV4V", allows to demonstrate the function of a four-way mixing valve in a hot water heating system. The four-way mixing valve in the heating system regulates the circulation and feed flow temperatures of...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TEIS

Sanitary Fittings Training Unit

The Sanitary Fittings Training Unit, "TEIS", has been designed by EDIBON for training in the plumbing sector. It consists of an anodized aluminum frame and panels in painted steel in which tests can be carried out with the most common systems of...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TIAP

Drinking Water Installation Unit

The Drinking Water Installation Unit, "TIAP", has been designed to demonstrate domestic water heating from the cold water supply. A typical domestic drinking water system is attached to the front panel of the unit. The unit includes the most...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TPAP

Protection of Drinking Water Training Unit

The Protection of Drinking Water Training Unit, "TPAP", has been designed by EDIBON to study cases in which the drinking water system is contaminated with wastewater. It is specially designed for the training of students in the plumbing sector.The...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TELT

Pipe Cleaning Training Unit

The Pipe Cleaning Training Unit, "TELT", designed by EDIBON, simulates a real house piping system, so original components used in plumbing systems are employed.The objective of this unit is to study the cleaning of pipes from the sanitation...

9.10.3.- INSTALLATIONS- UND WARTUNGSPRAXIS

TSID

Sewerage Unit

With the Sewerage Unit, "TSID", tests about a wastewater sanitation system can be made and the flow in a sewage system can be observed.A complete sewage system can be observed with the "TSID" unit. The collection of wastewater from a series of...

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen